2025 Industry Trends: Unlocking the Potential of the Best Flexo Printing Machines

As we look ahead to 2025, the flexo printing industry is poised for significant transformation, driven by technological advancements and evolving market demands. According to a recent report by Smithers Pira, the flexographic printing market is expected to grow at a CAGR of 3.8%, reaching an estimated value of $50 billion by 2025. This surge is largely attributed to the increasing adoption of eco-friendly inks and the demand for high-quality, quick-turnaround packaging solutions. Flexo printing machines are at the forefront of this evolution, offering versatility, efficiency, and superior print quality. In this blog, we will delve into the detailed technical specifications of the best flexo printing machines on the market, while also exploring best practices for their operation to maximize productivity and unlock their full potential in modern manufacturing.

The Evolution of Flexo Printing Technology: Key Developments to Watch in 2025

The flexographic printing industry is poised for substantial advancements in 2025, largely driven by technological innovations and evolving market demands. According to Smithers Pira’s latest report, the global flexographic printing market is expected to grow at a CAGR of 4.7%, reaching a valuation of $20 billion by 2025. This growth is propelled by the rising popularity of sustainable printing processes and the increasing need for high-quality packaging solutions, particularly in sectors like food and beverage, where consumer preferences are shifting towards eco-friendly materials.

Key developments to watch include the integration of digital technologies into flexo printing, creating a hybrid model that combines speed and efficiency with high-quality output. The introduction of smarter anilox technology, which allows for more precise ink transfer, will also enhance productivity and reduce waste. Furthermore, advancements in automation and AI-driven systems are set to streamline operations, leading to faster turnaround times and greater flexibility for manufacturers. As companies prioritize innovation, the potential of the best flexo printing machines will be unlocked, allowing them to meet the growing demands of a dynamic marketplace.

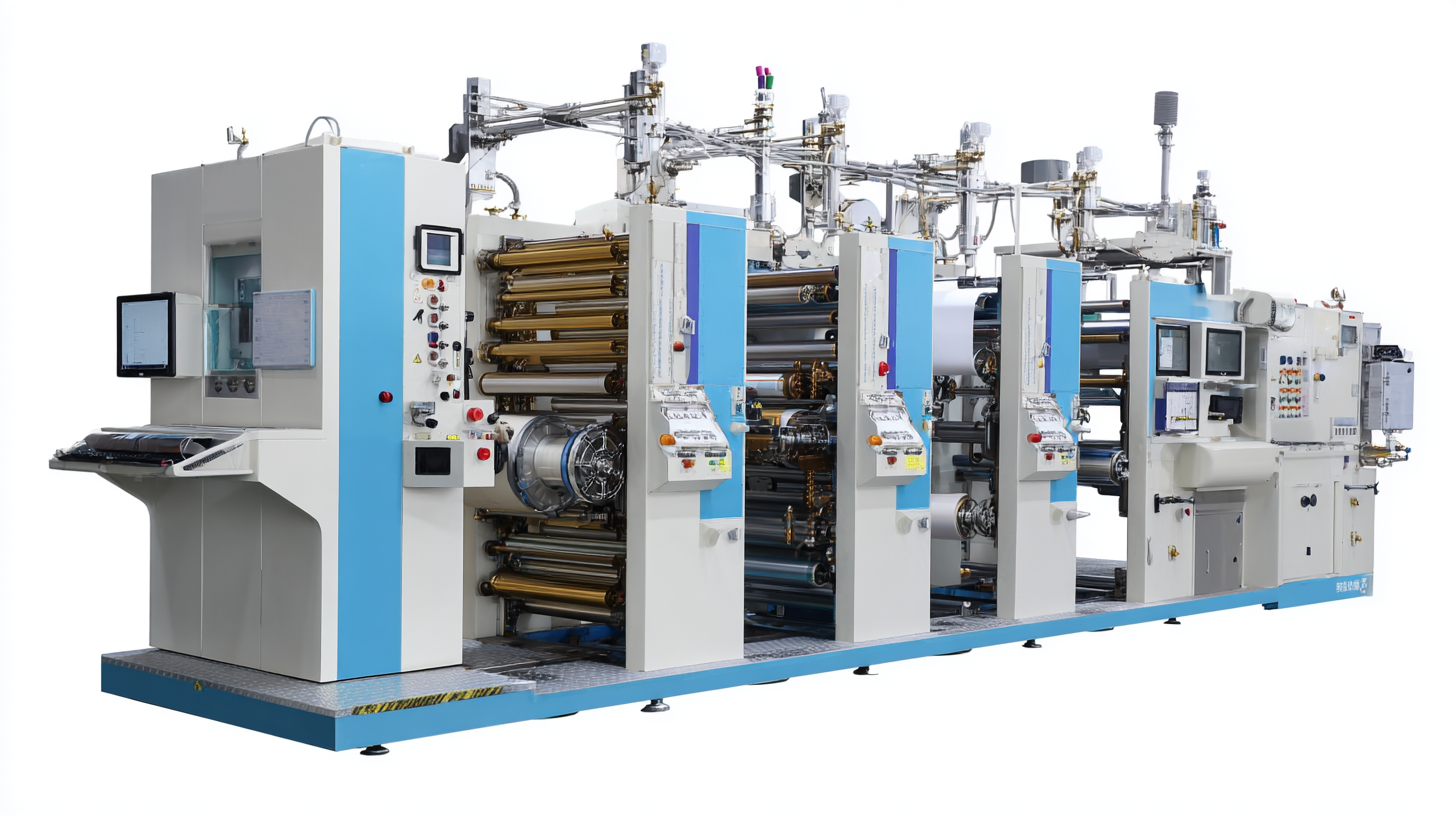

Top Features of the Best Flexo Printing Machines: What Sets Them Apart?

As the flexographic printing industry continues to evolve, identifying the top features of the best flexo printing machines becomes essential for businesses aiming to enhance efficiency and quality. According to a recent market research report by Smithers Pira, the global flexographic printing market is expected to reach $32 billion by 2025, highlighting the increasing demand for high-quality printing solutions. Features such as substrate versatility, speed capabilities, and automation play crucial roles in differentiating leading flexo machines from their competitors.

One standout feature of contemporary flexo printing machines is their adaptability to a variety of substrates, including flexible film, paper, and label stock. A 2022 report by the Technical Association of the Pulp and Paper Industry (TAPPI) found that machines designed to handle diverse materials without compromising print quality are favored by 67% of industry professionals. Additionally, advancements in automation technology, such as AI-driven quality control and ink management systems, have been shown to reduce operational costs by up to 20%, as noted in a study published by the Flexographic Technical Association (FTA). These capabilities not only streamline production processes but also ensure consistent, high-quality outputs that can meet the demands of modern consumers.

Sustainability Trends in Flexo Printing: Eco-Friendly Innovations on the Horizon

As the flexo printing industry evolves, sustainability is becoming a crucial focus area. A report by Smithers Pira indicates that the global market for eco-friendly printing solutions is set to reach $300 billion by 2025, reflecting a growing inclination towards sustainable practices.

Flexo printing, known for its versatility and efficiency, is at the forefront of this transformation, with innovations aimed at reducing waste and carbon footprints.

Flexo printing, known for its versatility and efficiency, is at the forefront of this transformation, with innovations aimed at reducing waste and carbon footprints.

One significant trend is the adoption of water-based inks, which not only offer lower VOC emissions but also enhance recyclability. According to a 2023 analysis by Market Research Future, the use of water-based inks in flexo printing is projected to grow by 15% annually as manufacturers and brands prioritize eco-friendly materials.

Additionally, advancements in plate technology are enabling better ink transfer and reducing the amount of material used, thereby decreasing overall waste. By embracing these eco-friendly innovations, the flexo printing industry is unlocking new potentials while meeting the pressing demands of sustainability.

Market Demand for Flexo Printing: Industries Driving Growth in 2025

In 2025, the flexo printing industry is poised for significant growth, driven by surging demand across diverse sectors such as packaging, labels, and textiles. According to a recent report by Smithers Pira, the global flexographic printing market is expected to reach approximately $42 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.5%. This expansion is fueled by the rising preference for sustainable printing solutions, as industries increasingly prioritize eco-friendly materials and practices.

Key players in the food and beverage packaging sector are leading this demand, with a projected increase in flexo printing usage by 30% in this field alone. Additionally, the e-commerce boom is propelling the need for flexible packaging solutions, as brands seek to enhance their supply chain efficiency. The shift towards digital printing technologies, complementary to flexo systems, is also influencing market growth, allowing for higher customization and reduced turnaround times. As industries adapt to these trends, the capabilities of advanced flexo printing machines will be pivotal in meeting evolving market demands and unlocking new opportunities for innovation.

Future Challenges for Flexo Printing: Navigating Competition and Technology Changes

As the flexo printing industry continues to evolve, businesses face the challenge of navigating intense competition and rapid technological advancements. Staying ahead requires a keen understanding of market trends and customer preferences. Adapting to changes not only ensures survival but also drives innovation.

Tip: Invest in training and continuous education for your workforce. As technology evolves, so do the skills required to operate advanced flexo printing machines. By upskilling employees, companies can maintain a competitive edge and optimize machine performance.

Moreover, integrating cutting-edge technology can streamline operations and enhance product quality. Companies must evaluate and incorporate smart solutions like automation and data analytics to improve production efficiency.

Tip: Regularly assess your equipment and consider upgrades. Investing in the latest flexo printing machines can result in superior output and lower long-term operating costs. This proactive approach equips businesses to tackle future challenges while maximizing growth potential.

2025 Industry Trends: Unlocking the Potential of the Best Flexo Printing Machines - Future Challenges for Flexo Printing: Navigating Competition and Technology Changes

| Trend | Description | Impact on Industry | Challenges |

|---|---|---|---|

| Sustainable Printing | Increased demand for eco-friendly materials and processes. | Higher customer loyalty and reduced environmental impact. | Cost of sustainable materials and regulatory compliance. |

| Automation | Integration of automated systems in flexo printing. | Increased efficiency and reduced labor costs. | Initial investment costs and training needs. |

| Digital Integration | Using digital technologies to enhance printing capabilities. | Flexibility in printing short runs and custom designs. | Integration complexities with existing systems. |

| Supply Chain Optimization | Improving supply chain efficiency and reducing lead times. | Increased competitiveness and customer satisfaction. | Dependency on suppliers and market fluctuations. |

| Advanced Inks | Development of high-performance, specialized inks. | Enhanced print quality and durability. | R&D costs and customer education on benefits. |