Exploring the 2026 Top Trends in the Automation Industry

The automation industry is experiencing rapid growth. Innovations are shaping how businesses operate daily. In 2026, we can expect pivotal trends that could redefine efficiency.

One major trend is the rise of AI-driven solutions. These tools automate existing processes, reducing human error. Yet, reliance on technology raises concerns about job displacement. Companies must find a balance between efficiency and employment.

Another crucial shift is the integration of Internet of Things (IoT) in automation. Smart devices connect seamlessly, boosting productivity. However, security issues persist. Protecting data is more important than ever in this evolving landscape. As the automation industry advances, reflection is essential for sustainable growth and responsibility.

The Rise of Artificial Intelligence in Automation Industry

The automation industry is undergoing a significant transformation, heavily influenced by the rise of artificial intelligence (AI). By 2026, it's predicted that AI will drive a 35% reduction in operational costs in automation processes. This statistic highlights the effectiveness of AI in enhancing efficiency and productivity. Companies are leveraging machine learning and AI algorithms to optimize workflows and reduce human error.

However, the rapid growth of AI presents challenges. Many organizations are still grappling with integrating these technologies into their existing systems. A report from the Global Automation Alliance noted that 70% of businesses face obstacles in AI adoption. This underscores the need for effective training and change management strategies. The fear of job displacement remains a significant concern, with many employees unsure about their future roles.

Another aspect of AI in automation is data security. As automation becomes more reliant on AI, the risk of cyber threats increases. According to Cybersecurity Ventures, cybercrime damages are expected to reach $10.5 trillion annually by 2025. This situation demands urgent attention. Many companies must invest more in cybersecurity measures alongside AI integration. Balancing innovation with security is crucial as the automation landscape evolves.

Integration of Internet of Things (IoT) in Automated Systems

The integration of the Internet of Things (IoT) in automated systems is reshaping industries. In 2022, the global IoT market was valued at approximately $300 billion, with growth projected at over 25% annually until 2026. This surge reflects the increasing reliance on connected devices to enhance operational efficiency and accuracy.

IoT-enabled automation allows real-time data collection and analytics. Systems can monitor their performance continuously. However, challenges remain. Interoperability between different IoT devices is often complex. Data security concerns also arise, with many firms reporting breaches. A recent study indicated that 30% of companies lack adequate cybersecurity measures for their IoT devices.

Despite these hurdles, the benefits of IoT in automation cannot be overlooked. Enhanced productivity is noticeable. In warehouses, automated systems reduce manual tasks, increasing efficiency by up to 40%. However, not all businesses are reaping these rewards equally. Small and medium enterprises often struggle with the initial investment. Balancing costs and benefits becomes a critical task for decision-makers. As industries evolve, the path forward will require thoughtful integration strategies.

Advancements in Robotics and Machine Learning Technologies

The automation industry is witnessing rapid advancements in robotics and machine learning technologies. According to a recent report from McKinsey, the global automation market is expected to reach $500 billion by 2026. This growth is driven by innovations that enhance productivity and efficiency in various sectors. However, challenges remain, particularly in integrating new technologies effectively.

Robotics today not only enhances manufacturing but also impacts logistics, healthcare, and even agriculture. A significant trend is the rise of collaborative robots, or cobots, which work alongside humans. About 70% of companies report increased interest in these systems. Yet, there are concerns regarding the adaptability of current workforces. Training initiatives often lag behind the speed of technological advancements.

Machine learning continues to revolutionize data analytics. Organizations are harnessing vast amounts of data to improve decision-making. However, reliance on automated insights can lead to overconfidence. A report from Gartner indicates that around 60% of AI projects fail to deliver expected results. This raises critical questions about accountability and transparency in automation applications.

Exploring the 2026 Top Trends in the Automation Industry

| Trend | Description | Impact | Expected Growth (%) |

|---|---|---|---|

| AI-Driven Robotics | Robots enhanced with AI capabilities for better problem-solving. | Increased efficiency and effectiveness in manufacturing processes. | 45% |

| Collaborative Robots (Cobots) | Robots designed to work alongside humans in shared workspaces. | Enhancing human-robot collaboration and productivity. | 35% |

| Edge Computing | Decentralizing data processing closer to the source for real-time decision-making. | Improvement in latency and operational efficiency. | 50% |

| Machine Learning Automation | Utilization of machine learning algorithms for process automation. | Reduction in human error and increased automation rates. | 60% |

| Smart Manufacturing | Leveraging IoT devices for efficient manufacturing processes. | Greater resource management and operational transparency. | 70% |

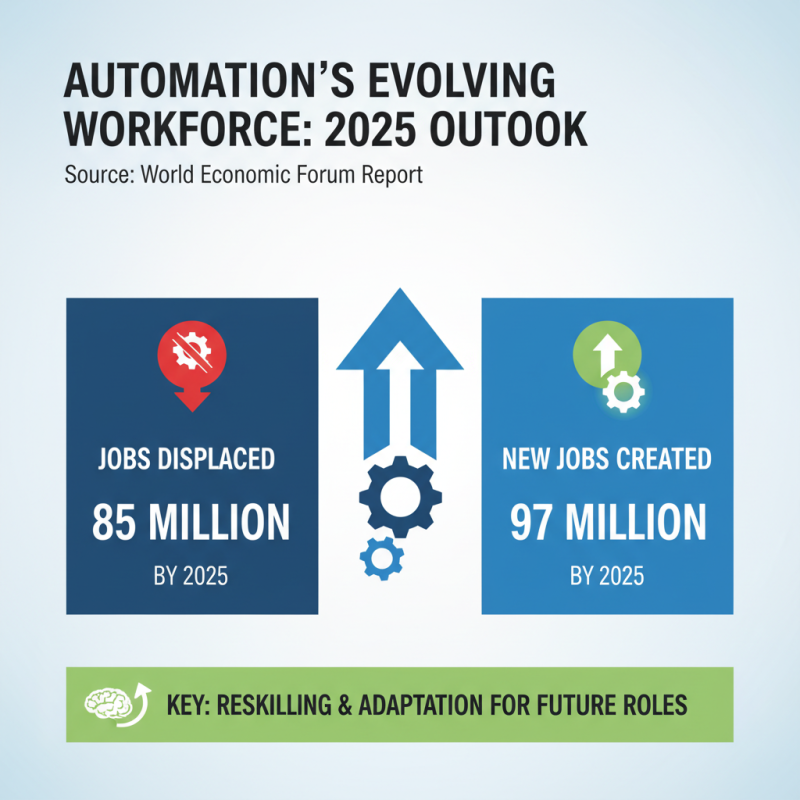

Impact of Automation on Workforce Dynamics and Employment Trends

The automation industry is rapidly evolving, reshaping workforce dynamics and employment trends. According to a report from the World Economic Forum, automation could displace 85 million jobs by 2025. However, it also creates 97 million new roles, emphasizing the need for reskilling. Workers must adapt to these changes to remain relevant in the job market.

Automation enhances efficiency but raises concerns. Many industries experience a skills gap due to the swift adoption of technology. For example, manufacturing and logistics sectors are integrating robots for tasks like assembly and delivery. This shift creates a demand for tech-savvy employees who can operate and maintain these systems. Yet, not everyone is equipped to meet these new challenges.

The transition is not seamless. Workers in routine jobs often feel anxious about their future. A recent survey indicated that 60% of employees fear automation will endanger their positions. This uncertainty necessitates a collective effort from industry leaders and educators to address workforce readiness. Ensuring equitable access to training programs can mitigate disparities and safeguard livelihoods.

Sustainability Practices and Energy Efficiency in Automation Solutions

Sustainability in the automation industry is gaining considerable attention. Companies are increasingly focusing on reducing energy consumption. Innovative technologies are being developed to create more energy-efficient solutions. For instance, smart sensors can optimize energy use in real-time. This reduces waste and minimizes environmental impact.

Energy-efficient automation solutions are not just about technology. They entail a shift in mindset. Organizations are starting to see the importance of green practices. However, some still struggle with implementation. There are challenges in integrating sustainability into existing systems. Employees may resist changes, fearing disruption. This resistance must be addressed thoughtfully.

Despite these hurdles, the potential benefits are significant. Improved energy efficiency leads to cost savings over time. It also enhances brand reputation. Industry leaders are likely to push for cleaner solutions. This effort might still be a work in progress, but the direction is clear. The future of automation must harmonize with sustainability. Only then can we achieve lasting improvements.

Related Posts

-

How to Implement Robotic Automation in Your Business for Maximum Efficiency

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

Understanding the Essence of Robotics: What Defines a Robot in Today’s Tech Landscape

-

What is Robotics and Automation and How It Transforms Industries Today

-

10 Best Robot Machines for Efficient Automation in 2023

-

Top 5 Reasons Why Fanuc Robots Lead the Automation Industry with 20 Percent Market Share