Exploring Alternatives to the Best Slitting Machine: Innovative Options That Enhance Efficiency and Precision

The demand for precision and efficiency in manufacturing processes has driven significant advancements in slitting technology, with the global slitting machine market projected to reach USD 2.1 billion by 2026, growing at a CAGR of 5.2% (Source: Market Research Future). Slitting machines play a crucial role in industries ranging from packaging to automotive, where exact cutting is essential for producing high-quality end products. However, as manufacturers face increased pressures for productivity and cost-effectiveness, exploring innovative alternatives to traditional slitting machines has become imperative. This blog will delve into various types of slitting machines and alternative options that not only enhance efficiency and precision but also cater to diverse product characteristics and applications. By understanding these innovations, businesses can better adapt to the evolving marketplace and optimize their production processes.

Understanding Slitting Machines: Types and Technologies Available

Slitting machines are essential in various industries for processing materials into desired widths and lengths, and understanding their types and technologies is crucial for businesses looking to enhance efficiency and precision. The advancements in slitting machines, particularly in laser cutting technology, have revolutionized how materials are cut and shaped. Laser-cutting machines utilize focused, high-powered beams to deliver precise cuts, allowing for intricate designs and a smoother finish, making them a highly sought-after option in sectors ranging from garment manufacturing to jewelry creation.

Moreover, the rise of CNC plasma cutting machines illustrates the growing demand for automated solutions that enhance productivity. The global market for these machines is projected to grow significantly, reflecting the trend towards automation in manufacturing processes. As we delve deeper into the technological landscape, innovations such as advanced robotics and AI are also transforming the garment industry, streamlining cutting and sewing processes. This shift emphasizes the importance of exploring alternative slitting technologies that not only increase operational efficiency but also adapt to the evolving needs of industries.

The Importance of Precision in Slitting: Why Alternative Solutions Matter

Precision is paramount in the slitting process, influencing the quality and performance of the final product. Traditional slitting machines, while effective, often come with limitations such as high maintenance costs and the inability to accommodate diverse material types. In today’s fast-paced manufacturing landscape, businesses are seeking alternatives that not only enhance efficiency but also ensure precise cuts tailored to specific applications. This shift is driven by the need to minimize waste and optimize production times, making innovative solutions more attractive.

Alternative slitting technologies, such as rotary knife systems or advanced laser cutting, offer unique advantages. These methods reduce mechanical wear and tear, resulting in lower operational costs and less downtime. Moreover, modern alternatives are designed with adaptability in mind, allowing manufacturers to easily switch between different slitting configurations. By investing in these innovative options, companies not only improve their cutting precision but also position themselves competitively in a market that increasingly prioritizes quality and efficiency. Embracing these advancements can lead to significant gains in productivity and a stronger product offering.

Exploring Alternatives to the Best Slitting Machine: Innovative Options That Enhance Efficiency and Precision

| Alternative Solution | Efficiency Improvement (%) | Precision Level (μm) | User Satisfaction Rating (1-10) |

|---|---|---|---|

| Laser Slitting Technology | 30 | 10 | 9.5 |

| Rotary Shear Blades | 25 | 15 | 8.7 |

| Water Jet Cutting | 20 | 8 | 9.0 |

| Ultrasonic Cutting | 15 | 12 | 9.2 |

| Die Cutting Machines | 10 | 20 | 8.0 |

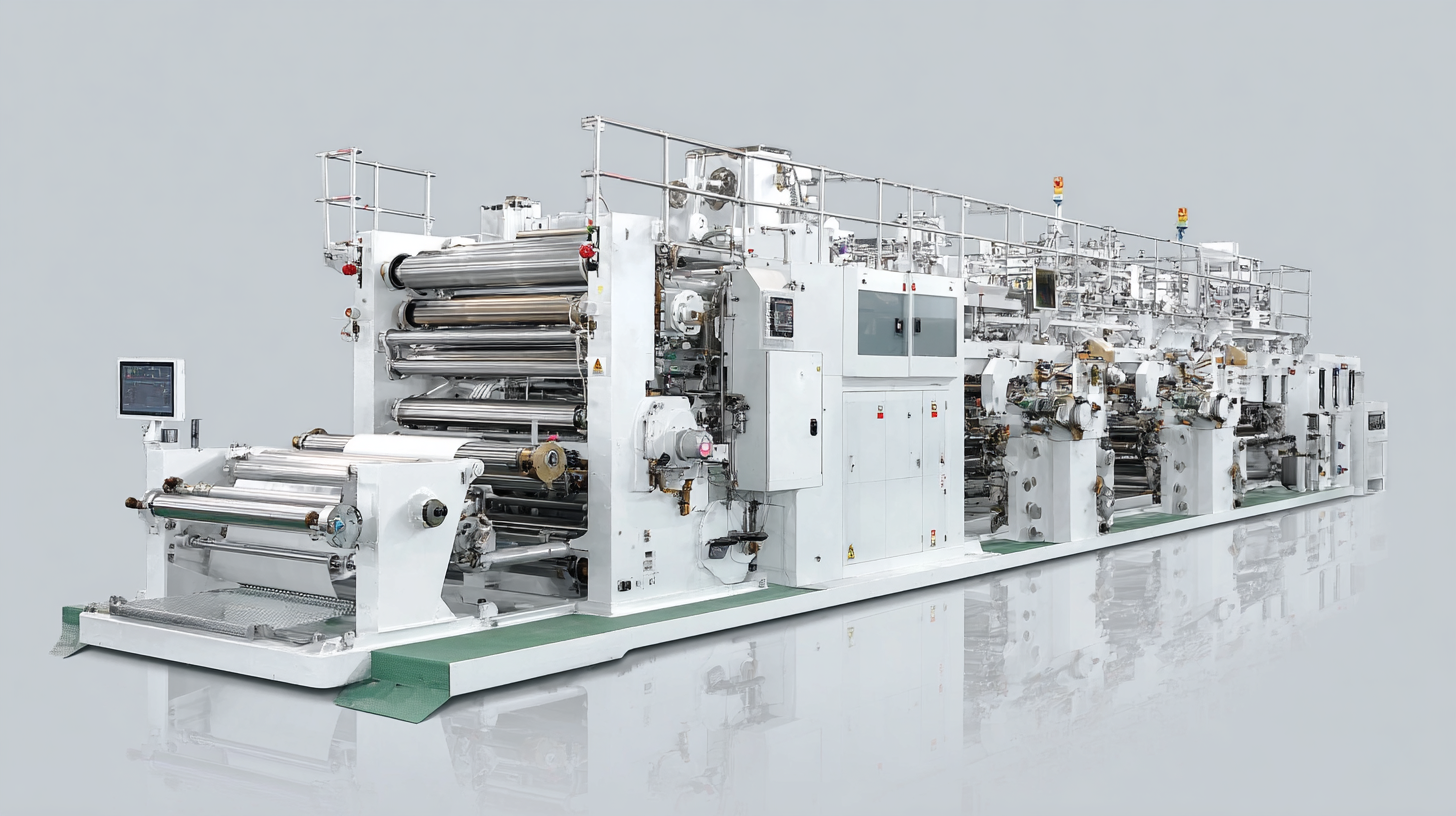

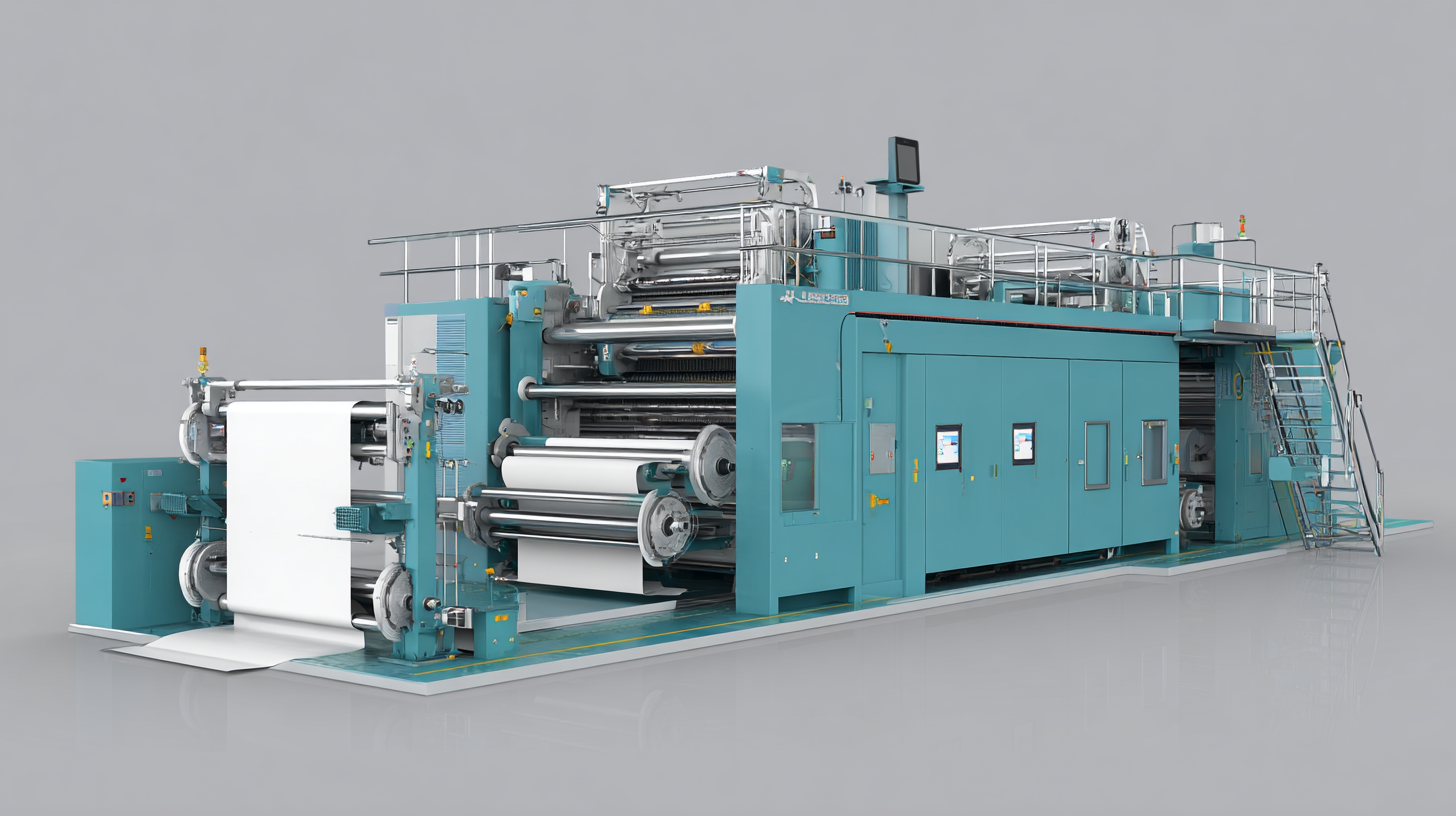

Innovative Design Features of Modern Slitting Machines

Modern slitting machines have undergone significant transformations, incorporating innovative design features that enhance both efficiency and precision. One of the standout advancements is the integration of automated blade height adjustment systems, which allow for quick and accurate modifications. This not only reduces downtime but also ensures that the slitting process remains consistent across various materials and thicknesses. The ability to fine-tune blade positions without manual intervention is a game-changer, especially in environments that require high-volume production runs.

Another remarkable feature is the implementation of advanced control systems that leverage real-time monitoring and data analytics. These systems provide operators with detailed feedback on the slitting process, allowing for immediate adjustments and minimizing waste. By utilizing sensors and automated feedback loops, modern slitting machines can detect irregularities in material flow and adapt accordingly. This level of precision not only improves product quality but also enhances operational efficiency, enabling manufacturers to meet tight production deadlines while maintaining exacting standards.

Additionally, the use of lightweight yet durable materials in the construction of slitting machines contributes to their efficiency. These innovative materials reduce the machine's overall weight, making installation and mobility easier without compromising strength. Together, these design improvements signify a leap forward in slitting technology, emphasizing a future where efficiency and precision go hand in hand.

Evaluating Efficiency: The Best Practices in Slitting Machine Alternatives

In the competitive landscape of manufacturing, efficiency often dictates success, prompting businesses to seek alternatives to traditional slitting machines. Evaluating efficiency in slitting operations begins with understanding various practices that enhance both productivity and precision. One increasingly popular practice is the integration of advanced automation systems that minimize human error and optimize workflow. By incorporating sensors and data analytics, manufacturers can monitor cutting processes in real-time, allowing for immediate adjustments that lead to improved output quality.

Another effective alternative is the shift towards modular slitting technology, which allows companies to customize their setups based on specific production needs. This adaptability means that businesses can swiftly switch between different materials and specifications without significant downtime, ensuring that they remain agile in responding to market demands. Furthermore, investing in high-quality knife materials and coatings can substantially enhance the lifespan and performance of slitting blades, reducing costs associated with replacements and maintenance. By embracing these best practices, manufacturers can unlock new levels of efficiency and precision in their slitting operations.

Exploring Alternatives to the Best Slitting Machine

This chart evaluates the efficiency ratings of various alternatives to traditional slitting machines. The ratings are based on observed performance during production processes, illustrating the strengths of each technology in enhancing precision and efficiency in materials processing.

Future Trends in Slitting Technology: What to Expect Next

As slitting technology continues to evolve, several innovative trends are emerging that promise to enhance both efficiency and precision within the industry. One significant advancement lies in the integration of laser technology into traditional slitting processes.

Laser slitting machines are gaining traction due to their ability to provide intricate cuts with minimal material waste. This shift not only reduces operating costs but also enhances the quality of the final product—an essential factor for manufacturers who strive to meet increasingly stringent quality standards.

Laser slitting machines are gaining traction due to their ability to provide intricate cuts with minimal material waste. This shift not only reduces operating costs but also enhances the quality of the final product—an essential factor for manufacturers who strive to meet increasingly stringent quality standards.

Another trend is the adoption of automation and smart technology in slitting machines. With the advancement of Industry 4.0, machines are becoming smarter, incorporating IoT capabilities for real-time monitoring and analytics. This allows operators to optimize production schedules, predict maintenance needs, and enhance overall efficiency through data-driven decision-making. As the demand for more agile and responsive manufacturing systems grows, the next generation of slitting technology will likely prioritize these smart features, making it easier for manufacturers to adapt to changing market conditions and consumer preferences.