Top 10 Benefits of Robotic Automation Process in Modern Industry?

In the rapidly evolving world of industry, the adoption of the robotic automation process has become paramount. Experts like Dr. Linda Chen, a leading figure in automation technology, emphasize, "Robotic automation is not just the future; it’s the present transforming how we operate." This sentiment highlights the growing significance of robotic automation in enhancing operational efficiency.

Today’s industries face unique challenges, including labor shortages and increased demand for precision. The robotic automation process addresses these issues effectively. For instance, in manufacturing, robots enhance production rates and reduce human error. This transformation allows for more consistent quality and timely output.

However, as beneficial as it is, the robotic automation process raises some concerns. Workers might feel threatened or uncertain about job security. Furthermore, the reliance on automation can lead to complacency. Industries must balance efficiency with the human element to create an ideal working environment. This nuanced perspective is vital as we navigate the future of industrial automation.

Benefits of Robotic Automation in Increasing Operational Efficiency

Robotic automation is transforming modern industry, particularly in improving operational efficiency. Automation reduces human involvement in repetitive tasks. This shift allows companies to allocate human resources to more strategic roles. As machines handle boring tasks, workers can engage in innovation and problem-solving.

Efficient robotic systems minimize errors. They can work tirelessly, leading to increased production rates. This speed boosts overall productivity, which is crucial for today’s competitive landscape. However, integrating robotics can present challenges. Staff may resist new technologies. Training is often required to ensure smooth transitions.

Another aspect worth considering is maintenance. Automated systems require regular checks to ensure they function optimally. Sometimes, unexpected breakdowns can cause delays. Despite these issues, the long-term benefits of increased efficiency often outweigh the drawbacks. Many industries are leaning toward automation, realizing its potential to optimize operations and enhance profitability.

Top 10 Benefits of Robotic Automation Process in Modern Industry

| Benefit | Description | Impact (%) |

|---|---|---|

| Increased Efficiency | Robots can operate continuously without breaks, leading to higher output. | 30% |

| Cost Reduction | Automation reduces labor costs and minimizes human error. | 25% |

| Improved Quality | Consistency in manufacturing processes leads to fewer defects. | 20% |

| Enhanced Safety | Automation decreases the risk of injury by taking over dangerous tasks. | 15% |

| Scalability | Easy to scale production up or down based on market demand. | 10% |

| Data Collection | Robots gather data for analysis, improving decision-making. | 10% |

| Flexibility | Robotic systems can be programmed for various tasks. | 8% |

| Improved Work Environment | Automation allows human workers to focus on more complex tasks. | 5% |

| Faster Response Time | Robots can respond quicker to production changes or needs. | 7% |

| Sustainability | Automation often results in less waste and better resource usage. | 5% |

Reduction of Human Error through Robotic Automation Technologies

The rise of robotic automation in industries has significantly reduced human error. In traditional manufacturing, mistakes can stem from fatigue, distraction, or even lack of training. Robots, however, operate consistently at peak efficiency. They follow precise algorithms, ensuring tasks are completed accurately, leading to more reliable production outcomes.

Consider an assembly line where robots handle repetitive tasks. These machines do not lose focus. They don’t suffer from the same physical or mental limitations as humans. As a result, the rate of defective products declines. Yet, the shift to robotic automation isn’t flawless. Initial programming errors can still lead to issues. Additionally, the reliance on robots can create challenges if they malfunction.

There are also concerns about job displacement and the skills gap. Workers may feel threatened by automation. This creates a need for retraining and adaptability. Industries must address these human aspects while embracing robotic excellence. Balancing automation and workforce needs can foster a more efficient and harmonious workspace. Such considerations are vital as technology continues to advance.

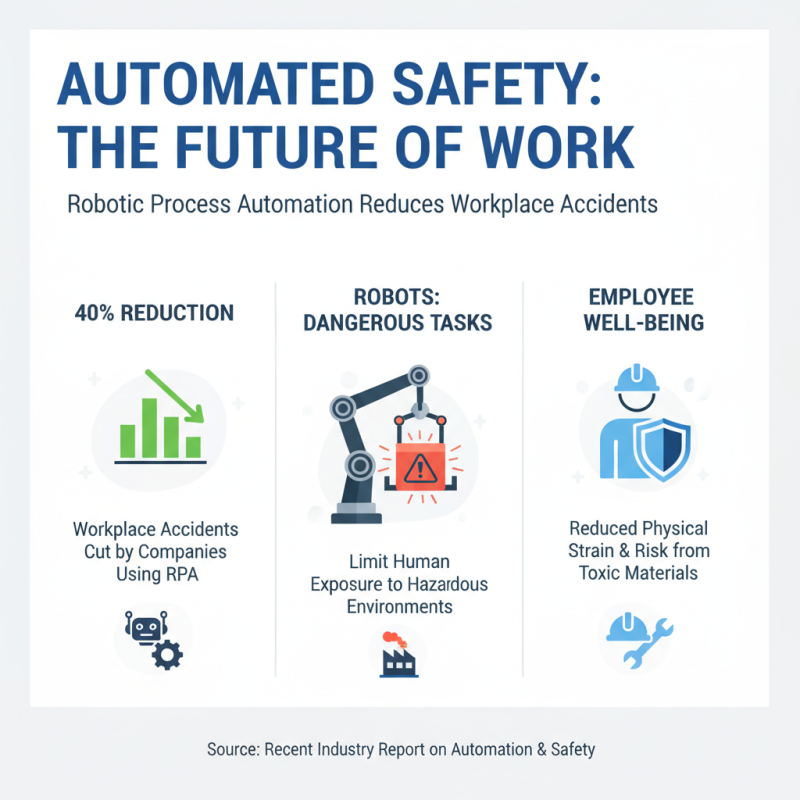

Enhancement of Workplace Safety with Automated Processes

Automated processes are transforming workplace safety in modern industries. According to a recent report, companies that incorporate robotic process automation can reduce workplace accidents by 40%. Robots take on dangerous tasks, limiting human exposure to hazardous environments. For instance, in manufacturing, robots handle heavy lifting or work with toxic materials. This minimizes physical strain and risk for employees.

One major benefit is the reduction of human error. A study indicated that 90% of industrial accidents are caused by human mistakes. Robotic systems operate with precision, lowering the chances of mishaps significantly. This reliability is crucial in environments where safety is paramount. Workers can focus on oversight and management instead of performing risky tasks.

Tips: Regularly assess robotic systems for performance. Ensure that maintenance schedules are strictly followed. Engage your workforce in discussions about safety improvements. Feedback from experienced employees can uncover overlooked risks. Investing in training programs that emphasize safe interactions with robots is essential. These steps foster a culture of safety and awareness.

Cost Savings Achieved through Robotic Automation Implementation

Robotic automation has transformed modern industries significantly. One of the key benefits is cost savings. By implementing robotic systems, companies can reduce labor costs. This is especially vital in low-margin industries where every penny counts. Robots can work tirelessly without breaks or overtime pay. This leads to higher production efficiency while minimizing operational expenses.

Additionally, robotic automation enhances precision and reduces errors. Human workers can make mistakes, especially in repetitive tasks. Robots, on the other hand, maintain high levels of accuracy. This decrease in errors often translates into less waste and lower costs. However, some businesses may struggle with the initial investment in automation technology. It requires careful planning and consideration. A hasty investment may not yield the expected savings.

Robots also offer scalability. Companies can quickly adjust production levels to meet demand. This flexibility can lead to cost-effective operations. Despite these advantages, not every business is ready for automation. Some sectors may find the transition difficult. These challenges highlight the need for thoughtful implementation strategies. Addressing concerns about workforce displacement is also crucial. Thus, while robotic automation can drive substantial savings, careful execution is essential.

Top 10 Benefits of Robotic Automation Process in Modern Industry

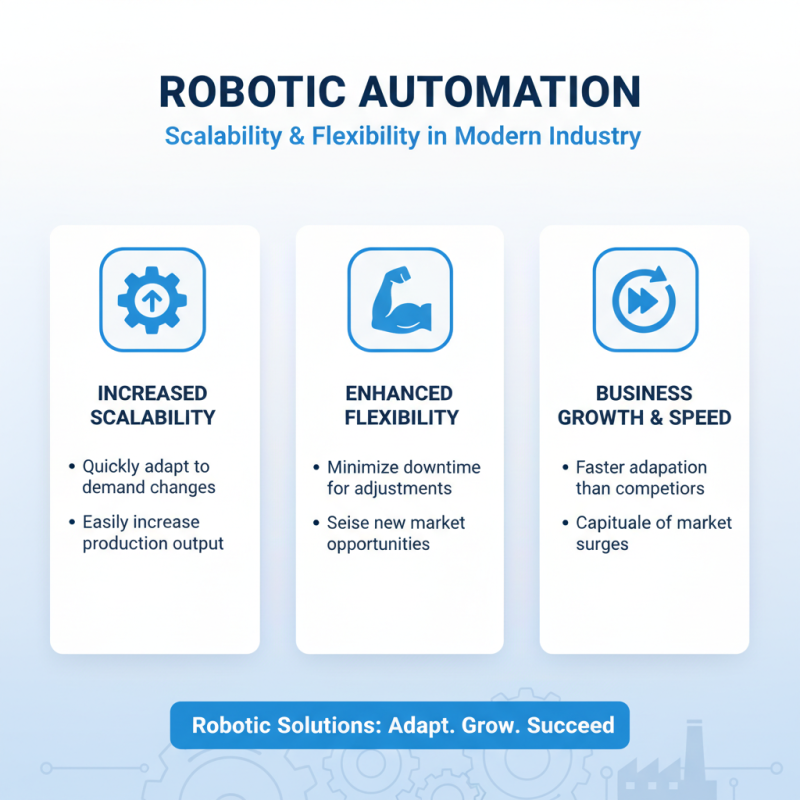

Scalability and Flexibility Offered by Robotic Automation Solutions

Robotic automation solutions significantly enhance scalability and flexibility in modern industry. Businesses can quickly adapt to changing demands. For example, if production needs surge, robotic systems can easily increase output without major downtime. This capability allows companies to seize new market opportunities faster than ever.

Flexibility is another key benefit. Robots can be reprogrammed for diverse tasks. This means a single robotic arm can handle different products throughout the day. Imagine a factory where one machine works on assembly in the morning and shifts to packaging in the afternoon. This versatility is appealing, but it can lead to challenges. Workers may need time to adjust to new workflows, creating initial disruption.

Moreover, implementing robotic automation is not without its hurdles. Companies need to invest time and resources in training. An incorrect setup could result in inefficiencies. Sometimes, managers might underestimate the complexity of integrating robotics with existing systems. Balancing automation with human talent requires ongoing reflection and adaptation, but the potential rewards can transform production landscapes.

Related Posts

-

What is Robotics and Automation and How It Transforms Industries Today

-

Top 5 Reasons Why Fanuc Robots Lead the Automation Industry with 20 Percent Market Share

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

Top 10 Robotic Automation Solutions Transforming Businesses Today

-

10 Essential Tips for Implementing Robotic Automation in Your Business

-

How to Implement Robotic Automation in Your Business for Maximum Efficiency