Top 10 Benefits of Using Robotic Welders in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the integration of technology is crucial for enhancing efficiency and productivity. One remarkable innovation that has transformed welding processes is the adoption of robotic welders. As noted by industry expert Dr. Emily Chen, a leading figure in automation technology, "The precision and consistency offered by robotic welders have not only streamlined operations but also significantly improved product quality." This sentiment reflects the growing recognition of robotic welders as indispensable assets in factories across various sectors.

The benefits of utilizing robotic welders extend far beyond mere automation; they encompass increased speed, reduced labor costs, and enhanced safety measures. By employing advanced algorithms and state-of-the-art sensors, robotic welders can perform tasks with a level of accuracy that human welders may find challenging to achieve. This technological advancement enables manufacturers to meet stringent quality standards and fulfill high-volume orders with ease. As the demand for customized and high-quality products rises, the role of robotic welders in meeting these challenges becomes ever more prominent.

Moreover, as manufacturers look to stay competitive in a global market, investing in robotic welding technology is not just a trend; it’s a necessity. As Dr. Chen aptly puts it, "Embracing robotic welding is a strategic move that can set companies apart from their competitors." This outlook sets the stage for exploring the top 10 benefits of using robotic welders and their profound impact on modern manufacturing practices.

Advantages of Precision: How Robotic Welders Enhance Manufacturing Accuracy

Robotic welders are revolutionizing modern manufacturing by enhancing precision and accuracy in welding processes. Unlike traditional welding methods, robotic welders can maintain consistent quality with minimal variation. This is particularly critical in industries such as automotive manufacturing, where exact dimensions and strong welds are essential for safety and performance. The precision offered by robotic welders not only reduces defects but also improves the overall reliability of the products being manufactured.

**Tips:** When integrating robotic welders into your manufacturing process, consider conducting thorough training for your workforce. This ensures that operators can effectively work alongside these advanced machines, maximizing their benefits. Additionally, assess your production line to identify areas where robotic welding can be most impactful, allowing for smoother transitions and optimal use of resources.

Collaborative robots, or cobots, further enhance manufacturing accuracy by working alongside human operators. Their design allows for flexibility and adaptability in various production environments. This collaborative approach not only increases efficiency but also enhances safety, as cobots can take over repetitive or hazardous tasks, allowing skilled workers to focus on more complex processes. Investing in robotic welders and cobots is a forward-thinking strategy that positions manufacturing companies at the cutting edge of technology.

**Tips:** To fully leverage the capabilities of cobots, engage employees in the implementation phase. Their input can provide insights into the workflow, leading to better alignment between human skills and robotic functions.

Top 10 Benefits of Using Robotic Welders in Modern Manufacturing - Advantages of Precision: How Robotic Welders Enhance Manufacturing Accuracy

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Increased Precision | Robotic welders achieve higher accuracy in welding, reducing defects. | Enhances product quality and reduces rework costs. |

| Consistency and Uniformity | Robots provide consistent welding results over large production runs. | Ensures uniformity across products, increasing overall satisfaction. |

| Reduced Labor Costs | Automation reduces the need for manual labor in welding operations. | Lower operational costs and potential for reallocating human resources. |

| Enhanced Safety | Robotic welders minimize human exposure to dangerous environments. | Improves workplace safety and reduces injury rates. |

| Higher Production Speed | Robotic systems can operate continuously and at faster rates than humans. | Increases overall productivity and meets demand quickly. |

| Flexibility and Adaptability | Robots can be reprogrammed for different tasks without significant downtime. | Allows quick adaptation to changing manufacturing needs. |

| Quality Control | Integrated sensors and vision systems monitor weld quality in real-time. | Further ensures product quality and compliance with standards. |

| Lower Material Waste | Precision welding reduces spillage and waste of materials. | Cost savings on materials and improved sustainability. |

| Data Collection and Analysis | Robots can gather data on performance and quality consistently. | Enables manufacturers to improve processes and decision-making. |

| Long-Term Cost Savings | Initial investment in robotics often pays off through efficiency gains. | Improves competitiveness and profitability over time. |

Boosting Efficiency: The Role of Automation in Reducing Production Time

The integration of robotic welders into modern manufacturing processes has revolutionized the industry, particularly in enhancing efficiency and reducing production time. According to a report by the International Federation of Robotics, companies utilizing automation have seen productivity gains of up to 30%. This significant increase comes from the ability of robotic welders to operate continuously, performing precise welds faster than human operators while minimizing the likelihood of errors or rework.

Moreover, a recent study by Deloitte emphasizes that automation can reduce manufacturing cycle times by nearly 50%. With robotic welders performing repetitive tasks, human workers can focus on more complex aspects of production, leading to better resource allocation and increased throughput. The ability to quickly adapt to changes in production demands—such as switching between different welding tasks without extensive downtime—further bolsters the competitive advantage of companies that embrace robotic welding technology.

As such, the role of automation is pivotal not only in streamlining operations but also in positioning companies for future growth and innovation.

Cost-Effectiveness: Analyzing the Economic Benefits of Robotic Welding Solutions

Robotic welding solutions deliver significant economic advantages to modern manufacturing, particularly through their cost-effectiveness. By integrating welding robots and collaborative robots (cobots) into production lines, companies can streamline operations and reduce labor costs. These automated systems not only enhance precision and consistency in welding processes but also minimize material waste, leading to substantial savings. As manufacturers strive to meet growing consumer demand while maintaining profitability, the adoption of robotic welding technologies becomes an attractive option.

Moreover, the financial benefits extend beyond direct cost savings. Robots enhance production speed and reduce downtime through reliable performance and maintenance. For instance, predictive maintenance powered by AI can foresee equipment issues before they lead to costly breakdowns, thereby maintaining operational efficiency. The investment in robotic welding technology translates into a competitive edge that allows manufacturers to scale operations efficiently, respond to market changes swiftly, and ultimately drive profitability in an increasingly demanding landscape.

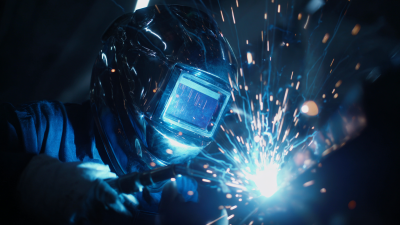

Safety First: How Robotic Welders Minimize Workplace Hazards

Robotic welders are revolutionizing modern manufacturing by enhancing safety standards in the workplace. One of the primary benefits of using these automated systems is their ability to operate in hazardous environments where human workers may be at risk. Robotic welders can handle dangerous tasks such as welding in confined spaces or high-temperature zones, significantly reducing the likelihood of accidents and injuries. By taking on the more perilous aspects of welding, robots create a safer atmosphere for human employees, allowing them to focus on oversight and quality control without the same level of exposure to danger.

Moreover, the implementation of robotic welding technology minimizes human error, which is often a significant contributor to workplace hazards. With precise programming and advanced sensors, robotic welders ensure consistent weld quality and reduce the chances of defects that could lead to unsafe conditions. This precision not only enhances the overall product quality but also strengthens structural integrity, which is vital in industries like automotive and construction. By prioritizing safety through automation, businesses can not only protect their workforce but also bolster their operational efficiency and productivity.

Versatility in Production: Adapting Robotic Welders to Diverse Manufacturing Needs

The versatility of robotic welders in modern manufacturing is one of their most significant advantages, allowing businesses to adapt to a wide array of production needs. According to a report by the International Federation of Robotics, the use of welding robots is projected to grow at a compound annual growth rate (CAGR) of 10% from 2020 to 2025. This growth is driven by advancements in technology that enable robots to be easily integrated into different manufacturing processes, whether for automotive assembly, aerospace components, or even intricate electronics production.

In addition to their adaptability, robotic welders enhance production efficiency across various industries. A study by Deloitte found that manufacturing companies that implement robotic welding can improve output by 30% while significantly reducing error rates and material waste. This capability allows manufacturers to maintain high-quality standards while being agile enough to respond to changing market demands, ultimately leading to better customer satisfaction and competitiveness in the global market. The ability to switch between different welding processes seamlessly makes robotic welders an invaluable asset for modern production lines.

Top 10 Benefits of Using Robotic Welders in Modern Manufacturing

Related Posts

-

Unlocking Business Efficiency with Robotic Process Automation Software Insights from Recent Industry Trends

-

Wisconsin Automation Leading the Future of Robotics in Manufacturing with Industry 4.0 Insights

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

10 Surprising Ways Automation Machines are Transforming Small Businesses in 2023

-

Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency

-

Exploring the Future of Automation Through Fanuc Robots Advancements in Technology