Best 10 Fanuc Robots for Automation in 2023

As we delve into the world of industrial automation in 2023, the role of robotic systems has become increasingly pivotal. Among the leading players in this field is the Fanuc robot, renowned for its versatility, precision, and reliability. In an era where efficiency and productivity are paramount, the integration of these advanced robots into manufacturing processes is transforming how businesses operate. This article highlights the best 10 Fanuc robots for automation, showcasing their unique features and applications across various industries.

Fanuc robots are designed to meet the diverse demands of modern automation, ranging from simple tasks to complex assembly operations. With cutting-edge technology, these robots offer unparalleled performance, making them a top choice for companies looking to enhance their operational capabilities. In the following sections, we will explore the top Fanuc robots available in 2023, analyzing their specifications, advantages, and the specific roles they play in boosting efficiency and reducing operational costs in different sectors. Whether you are a seasoned automation expert or a business owner contemplating robotic integration, understanding these innovative systems will equip you with the knowledge to make informed decisions in your quest for automation excellence.

Overview of Fanuc Robots in Automation

Fanuc robots have established themselves as a cornerstone in the automation industry, renowned for their reliability, precision, and versatility. According to a report by Statista, the global industrial robotics market is projected to reach approximately $40 billion by 2025, with Fanuc being one of the leading brands. Their robots serve a wide range of applications, from assembly and welding to material handling, making them pivotal for manufacturing efficiency. The integration of AI and machine learning in Fanuc robots further enhances their productivity, allowing for smarter operations that adapt to real-time changes on the production line.

When considering the implementation of Fanuc robots, it's crucial to evaluate your specific automation needs. Conducting a thorough analysis of your workflow can identify areas where robotics can significantly increase efficiency and reduce labor costs. Additionally, the ongoing support and training provided by Fanuc can help ensure a smooth transition to automated processes.

Tip: Always consider the scalability of your robotic solutions; choosing models that can adapt to future needs will provide long-term benefits. Furthermore, investing in regular maintenance can prevent downtime and extend the life of your robots, ensuring they continue to meet your production demands.

Key Features of Fanuc Robots for Industrial Applications

When exploring the best Fanuc robots for industrial automation in 2023, it's essential to focus on their key features that drive efficiency and productivity. Fanuc robots are known for their versatility, allowing for applications across various sectors such as manufacturing, automotive, and logistics. Their modular design enables easy integration into existing systems, facilitating smooth upgrades and scalability.

Another prominent feature is their advanced precision and speed, which significantly enhance production rates while maintaining high-quality standards. Many Fanuc robots are equipped with AI-driven capabilities, enabling them to learn and adapt to complex tasks over time, thus reducing human intervention and errors.

**Tip:** When selecting a Fanuc robot, consider the payload capacity and reach required for your specific application to maximize operational efficiency. Additionally, investing in models with easy programming interfaces can streamline training and deployment processes. With the right choices, Fanuc robots can be a game-changer in your automation strategy, optimizing performance and minimizing downtime.

Best 10 Fanuc Robots for Automation in 2023

| Model | Payload Capacity (kg) | Reach (mm) | Degrees of Freedom | Key Applications |

|---|---|---|---|---|

| M-20iA | 20 | 1810 | 6 | Pick and Place, Packaging |

| M-10iA | 10 | 1200 | 6 | Assembly, CNC Tending |

| R-2000iC | 210 | 2050 | 6 | Welding, Material Handling |

| LR Mate 200iD | 7 | 717 | 6 | Small Part Handling, Inspection |

| M-1iA | 5 | 600 | 6 | Palletizing, 3D Printing |

| S-2000iC | 150 | 2500 | 6 | High-Speed Applications, Automation |

| Adept Viper 600 | 6 | 600 | 6 | Pick and Place, Packaging |

| Lynx 6-Axis | 8 | 850 | 6 | Automated Quality Control |

| M-430iA | 30 | 1400 | 6 | Heavy Material Handling |

| R-30iB | 120 | 2200 | 6 | Custom Automation Solutions |

Top 10 Fanuc Robot Models for 2023

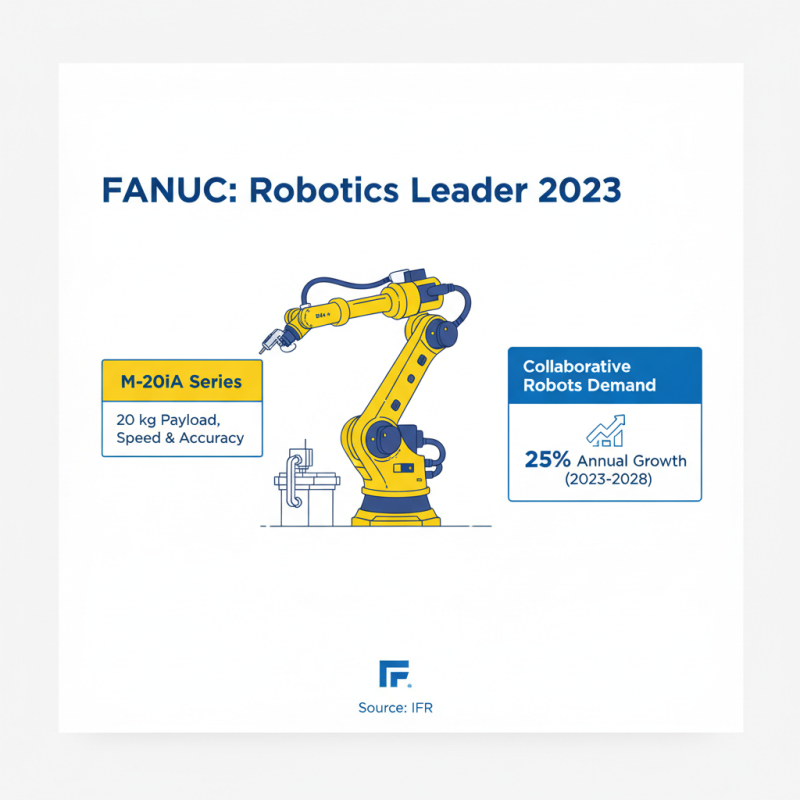

In 2023, Fanuc continues to lead the robotics industry with its advanced automation solutions, showcasing an array of models tailored to diverse manufacturing needs. Notably, the Fanuc M-20iA series stands out for its versatility, handling a payload of up to 20 kg while providing exceptional speed and accuracy. According to the International Federation of Robotics (IFR), the demand for such collaborative robots has grown significantly, with a projected annual growth rate of 25% in the next five years as industries increasingly automate their processes.

Additionally, the Fanuc LR Mate 200iD series has gained attention for its compact design and flexibility, making it ideal for small to medium-sized enterprises. This model boasts a reach of 911 mm and is capable of performing a variety of tasks, from assembly to packaging. The 2023 World Robotics Report highlights that incorporating such robots can enhance productivity by up to 40%, demonstrating the critical role of automation in sustaining competitiveness in an evolving market. As Fanuc's technology evolves, it remains at the forefront of enhancing operational efficiency across various sectors.

Comparative Analysis of Fanuc Robots by Industry

In 2023, automation continues to evolve across various industries, with Fanuc robots leading the charge due to their versatility and precision. A comparative analysis of Fanuc robots by industry shows distinct applications and advantages. For instance, in the automotive sector, the integration of Fanuc's LR Mate series has proven substantial, with a reported 30% increase in production efficiency over traditional methods (International Federation of Robotics, 2022). These robots excel in tasks such as welding, painting, and assembly, where speed and accuracy are paramount.

Meanwhile, in the electronics manufacturing domain, Fanuc's M-20iA model stands out, particularly for its lightweight design and high-speed performance. A study by MarketsandMarkets indicates that the electronics industry is projected to grow at a CAGR of 7.3% from 2022 to 2027, driving demand for robots capable of handling delicate components (MarketsandMarkets, 2021). Fanuc robots are equipped with advanced vision systems that enhance their ability to and are adapted to the intricate needs of handling and assembling electronic devices, thus cementing their role as essential tools for efficiency and quality assurance in this rapidly evolving field.

Future Trends in Fanuc Robotics Technology

The evolution of Fanuc robotics technology in 2023 is characterized by advanced machine learning capabilities and enhanced connectivity. As industries demand more intelligent automation solutions, Fanuc has responded by integrating

artificial intelligence into their robotic systems. This pivot allows robots to learn from their environments, adapt to new tasks without extensive reprogramming, and collaborate more efficiently with human workers. Such advancements not only improve productivity but also significantly reduce downtime in manufacturing processes.

Moreover, the incorporation of IoT (Internet of Things) in Fanuc robots facilitates real-time data exchange and monitoring. This capability enables predictive maintenance, allowing companies to anticipate equipment failures before they occur, thereby optimizing operational efficiency. As Fanuc continues to pioneer in robotics technology, the focus is shifting toward creating more versatile and user-friendly robots that can seamlessly operate in various environments, from assembly lines to service sectors. This trend points towards a future where automation is not only reliable but also intuitive, enhancing overall human-robot collaboration in diverse industrial applications.

Related Posts

-

Unlocking Business Efficiency with Robotic Process Automation Software Insights from Recent Industry Trends

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

Exploring the Future of Automation Through Fanuc Robots Advancements in Technology

-

Wisconsin Automation Leading the Future of Robotics in Manufacturing with Industry 4.0 Insights

-

What is Robotics and Automation and How It Transforms Industries Today

-

10 Best Robot Machines for Efficient Automation in 2023