10 Best Industrial Robots for Automation in Manufacturing?

In the evolving landscape of manufacturing, "robot industrial" solutions play a pivotal role in enhancing efficiency. Experts like Dr. Jane Smith, a renowned figure in automation, believe, "Industrial robots are revolutionizing how we think about production." This technology transforms not just processes but entire industries.

As companies embrace automation, the selection of the right robots becomes crucial. The variety of options can be overwhelming. Factors such as cost, functionality, and integration complexity should be considered. Companies often underestimate the learning curve associated with these advanced systems. The investment, though significant, must be planned carefully to avoid potential setbacks.

Moreover, the impact of "robot industrial" technology isn't solely positive. While efficiency increases, there are concerns about workforce displacement. Industries must navigate these challenges cautiously. Striking a balance between innovation and the human element remains a pressing issue. As we explore the ten best industrial robots for manufacturing, we must reflect on both their potential and their implications.

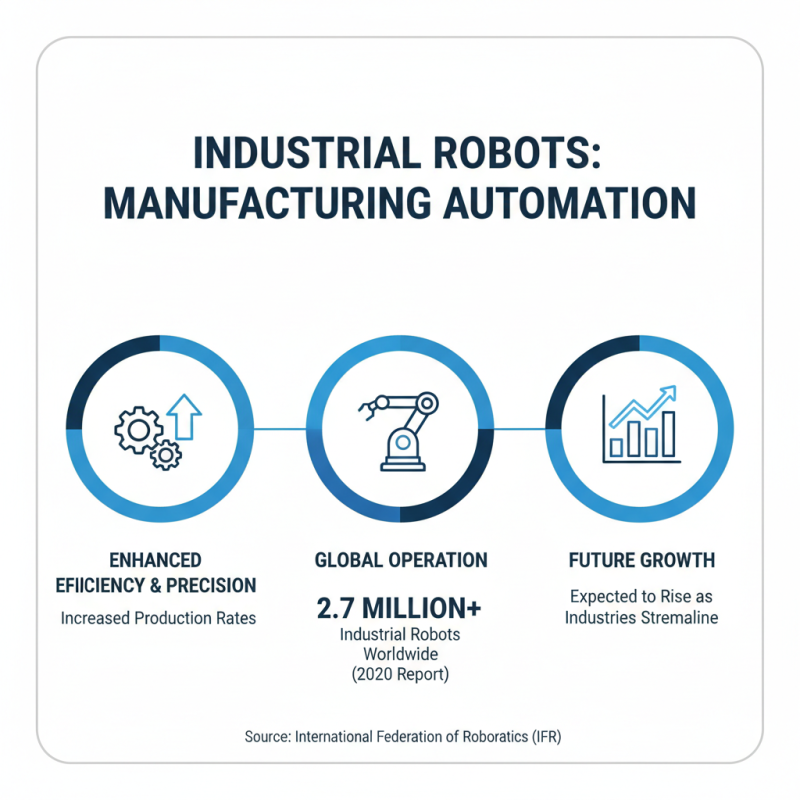

Overview of Industrial Robots in Manufacturing Automation

Industrial robots are revolutionizing manufacturing automation. These machines enhance efficiency and precision, leading to increased production rates. According to a report by the International Federation of Robotics, roughly 2.7 million industrial robots are in operation worldwide. This number is expected to rise as industries seek to streamline processes.

Manufacturers that utilize automation experience significant benefits. A study from McKinsey estimates that automation can increase productivity by up to 30%. However, not all businesses seamlessly adopt this technology. Many face challenges integrating robots into existing systems. Training personnel to work alongside robots remains an ongoing issue.

Cost is a major concern as well. Initial investments in robotic systems can be high. Smaller businesses often struggle to justify these expenses. Yet, the long-term gains can outweigh the initial costs. The key lies in careful planning and understanding the unique needs of the factory. Automation is not a one-size-fits-all solution, and businesses may need to rethink their strategies.

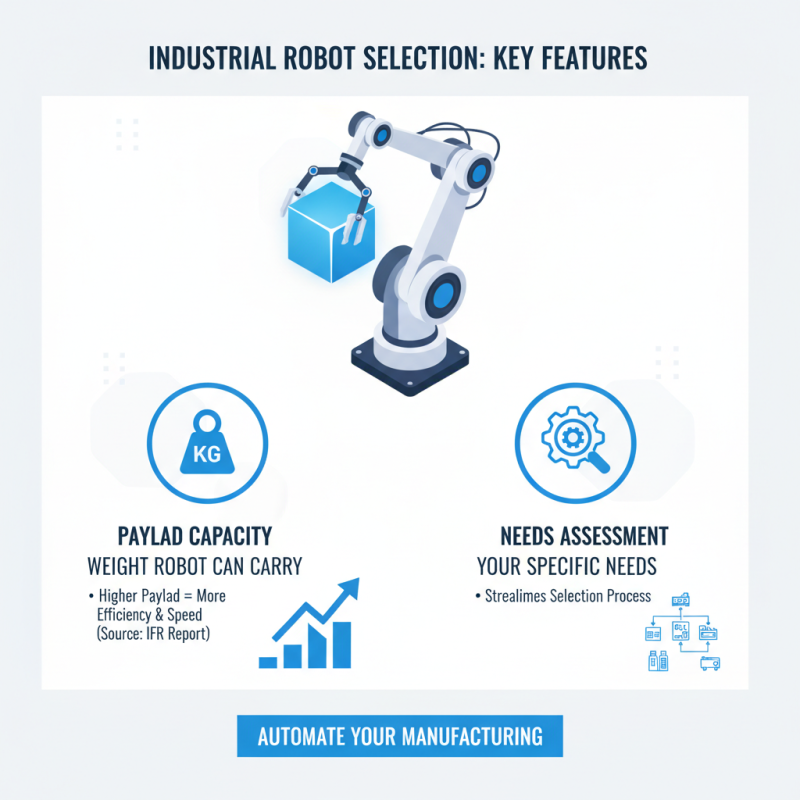

Key Features to Consider When Selecting Industrial Robots

When selecting industrial robots for manufacturing automation, there are key features to consider. Payload capacity is crucial. It refers to how much weight a robot can carry. A recent report by the International Federation of Robotics indicated that robots with higher payloads often outperform their lighter counterparts in efficiency and speed. Understanding your specific needs can streamline the selection process.

Another essential aspect is the robot's reach. The reach determines how far the robot can work from its base. Robots with longer reaches can cover more area, which may eliminate the need for multiple machines. Additionally, consider the robot's precision and repeatability. A 2021 study published in the Journal of Manufacturing Sciences shows that high-precision robots can improve production quality by up to 30%. While these features are vital, companies sometimes overlook their integration into existing systems. Compatibility issues can arise, leading to downtime and increased costs.

Finally, the flexibility of the robot cannot be ignored. Many tasks in manufacturing change frequently. Industries require robots that can be easily reprogrammed or redeployed. Flexibility allows a manufacturer to adapt quickly without significant investments. This adaptability is often reported as a decisive factor by companies aiming to maintain their competitive edge in a rapidly changing market. Manufacturers must carefully evaluate these attributes to avoid common pitfalls and ensure long-term success.

Top 10 Industrial Robots for Enhancing Manufacturing Efficiency

Manufacturing efficiency is increasingly reliant on advanced industrial robots. These machines can work tirelessly, performing repetitive tasks with precision. For instance, robotic arms are commonly used for assembly tasks. They can handle heavy components, reducing manual labor risks. The speed of these robots enhances overall productivity.

However, implementing industrial robots is not without challenges. Training staff to work alongside these machines is crucial. Communication between the workforce and automated systems can be complicated. There are concerns about job displacement as well. Balancing automation with human roles is essential for long-term success.

Some robots excel in specific environments but struggle elsewhere. For example, robots designed for welding are highly effective, yet they may not perform well in different tasks. Additionally, compatibility with existing systems can pose integration problems. Manufacturers must consider these factors carefully when selecting robots. By addressing these challenges, businesses can enhance their manufacturing processes significantly.

10 Best Industrial Robots for Automation in Manufacturing

| Robot Model | Payload Capacity (kg) | Reach (mm) | Degree of Freedom | Application |

|---|---|---|---|---|

| Model A | 10 | 1500 | 6 | Welding |

| Model B | 15 | 1200 | 6 | Assembly |

| Model C | 20 | 1800 | 7 | Packaging |

| Model D | 12 | 1600 | 6 | Pick and Place |

| Model E | 8 | 1400 | 5 | Material Handling |

| Model F | 25 | 2000 | 6 | Inspection |

| Model G | 30 | 2200 | 7 | Painting |

| Model H | 18 | 1700 | 6 | Sorting |

| Model I | 22 | 1900 | 6 | Milling |

| Model J | 35 | 2500 | 7 | Cutting |

Comparative Analysis of Leading Industrial Robot Brands

Industrial robots have made significant strides in manufacturing. These machines boost productivity and accuracy across various sectors. A comparative analysis reveals key features that separate these robots. Factors like speed, payload capacity, and ease of programming are crucial. Potential users must carefully assess their needs before choosing a robot.

Tips: Always start with specific tasks in mind. Understand the workflow and limitations of your facility. Not all robots fit every environment.

Some brands excel in collaboration, providing safety features for human workers. Others focus on heavy lifting, with robust structures. Remember, a powerful robot may not be the best fit if flexibility is essential.

Tips: Consider future growth. A scalable solution may offer long-term benefits, even if it's a larger initial investment. It's important to weigh costs against potential gains realistically.

Future Trends in Industrial Robotics and Automation Technologies

The future of industrial robotics is promising yet complex. A recent report predicts a 20% annual growth in the robotics market by 2028. This shift is driven by the need for efficiency and precision in manufacturing. Companies are exploring collaborative robots, or cobots, which work alongside human workers. These robots enhance productivity but also raise questions about job displacement.

Emerging technologies like AI and machine learning are reshaping industrial robotics. With advancements in computer vision, robots can detect and adapt to their environment. A study found that 70% of manufacturers are investing in automation technologies. However, many struggle with integration. The transition can cause disruptions in workflow and efficiency. Training staff to work with new technologies is crucial yet often overlooked.

As industries evolve, there’s a growing emphasis on sustainability. Robots are being designed for energy efficiency. Using renewable energy sources aligns with global sustainability goals. However, the production and disposal of robots still pose environmental challenges. Balancing innovation with responsibility will be a key factor in the advancement of industrial robotics.

Related Posts

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

What is Robotics and Automation and How It Transforms Industries Today

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

How to Implement Robotic Automation in Your Business for Maximum Efficiency

-

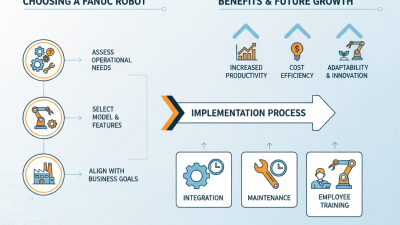

How to Choose and Implement a Fanuc Robot for Your Business Automation Needs

-

Top 10 Robotic Automation Solutions You Need to Know?