10 Best Robot Machines for Efficient Automation in 2023

In the rapidly evolving landscape of technology, robot machines are at the forefront of driving efficiency and automation across various industries. As businesses strive to enhance productivity and reduce operational costs, the adoption of advanced robotic solutions has become more critical than ever. This article explores the ten best robot machines of 2023 that are transforming processes and setting new benchmarks for automation.

From manufacturing to logistics, these innovative robots are designed to tackle repetitive tasks with precision, allowing human workers to focus on more strategic activities. Whether you are seeking to optimize workflows, improve safety standards, or boost overall performance in your organization, understanding the capabilities and functions of these robot machines is essential. Join us as we dive into the features and benefits of the top robotic solutions that can revolutionize your automation strategy and position your business for future success.

Top Features to Look for in 2023's Best Automation Robots

When exploring the best robot machines for automation in 2023, it's essential to focus on key features that enhance efficiency and usability. First and foremost, versatility is crucial. A robot capable of performing multiple tasks can significantly reduce costs and streamline operations across various sectors, from manufacturing to logistics. Moreover, seek out robots equipped with advanced AI capabilities, as these technologies allow for better decision-making and adaptability in dynamic environments.

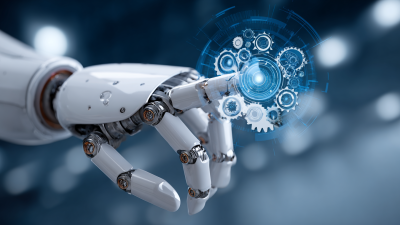

Another vital feature to consider is connectivity. Automation robots that support IoT integration can easily communicate with other devices, ensuring seamless data transfer and real-time updates. This connectivity can optimize workflows and improve overall productivity. Additionally, durability and ease of maintenance cannot be overlooked. Investing in robust robots that require minimal downtime for repairs can lead to a more efficient operation and extended service life.

Tips: When selecting a robot, assess its user interface; a simple, intuitive design can make a significant difference in ease of use. Regular updates from the manufacturer can also enhance a robot's performance, making it essential to choose models with a reliable support network. Lastly, consider energy efficiency as a parameter; robots that consume less power can lead to substantial savings in the long run.

Industries Benefiting Most from Robotic Automation Solutions

In 2023, various industries are experiencing significant growth from robotic automation solutions, notably manufacturing, logistics, and healthcare. The Industrial Robotics Services Market is projected to reach an impressive USD 41.6 billion by 2033, reflecting a compound annual growth rate (CAGR) of 35.4%. This surge in investment is largely driven by the need for efficiency and cost savings, as companies seek to enhance production rates and optimize material usage.

**Tips:** For businesses looking to integrate robotics, focusing on automation not only increases productivity but also ensures better product quality. Investing in robotic process automation (RPA) is particularly beneficial for small businesses that aim to streamline operations without extensive capital expenditure.

Furthermore, advancements in artificial intelligence are accelerating the evolution of robotics across multiple sectors. Humanoid and quadruped robots are leading innovations, with the quadruped robot market anticipated to grow from USD 2.5 billion in 2024 to USD 13.6 billion by 2034. Embracing these technologies provides companies with a competitive edge in an increasingly automated landscape.

Comparative Analysis of Leading Robot Machines for Efficiency

In the rapidly evolving landscape of automation, selecting the right robot machines is crucial for enhancing operational efficiency. This comparative analysis focuses on the leading robot machines available in 2023, evaluating their capabilities and performance. Factors such as speed, precision, and adaptability are paramount in determining their effectiveness across various industries. For instance, collaborative robots (cobots) designed for direct interaction with human workers have been gaining traction for their ability to improve production efficiency while ensuring safety.

Additionally, traditional industrial robots equipped with advanced AI algorithms demonstrate remarkable efficiency in high-volume production environments. The ability of these machines to learn and adapt to new tasks sets them apart, allowing businesses to scale operations quickly. Furthermore, integration with IoT technologies enhances their data collection and analysis capabilities, leading to smarter decision-making processes. This in-depth exploration aims to uncover the strengths and weaknesses of these robotic solutions, providing insights into which machines best meet specific automation needs and contribute to overall productivity in 2023.

10 Best Robot Machines for Efficient Automation in 2023

This chart represents the efficiency scores of the top 10 robot machines in automation for the year 2023. Each machine's efficiency is measured on a scale of 0 to 100.

Future Trends in Robot Technology and Automation Strategies

The global market for artificial intelligence is projected to grow exponentially, reaching an estimated $1.77162 trillion by 2032, with a remarkable compound annual growth rate (CAGR) of 29.2% from $294.16 billion in 2025. This surge in AI adoption will have profound implications across various sectors, particularly as automation continues to evolve. The impact on labor markets is significant, with reports suggesting that up to 10% of white-collar jobs could be at risk due to AI advancements. Furthermore, as companies like Amazon aim for 75% operational automation, a substantial number of blue-collar positions may also face elimination.

In industries such as manufacturing, automation trends are altering supply chains dramatically. The besieged landscape, characterized by labor shortages and unprecedented disruptions, demands an agile response. As identified by the Future Today Strategic Group, advancements in technologies such as embodied intelligence and intelligent robotics are anticipated to bring major breakthroughs within the industrial sector by 2025. Companies adopting automated solutions not only enhance efficiency but also streamline their operations, reducing overhead costs amidst escalating economic pressures.

Tips: To better navigate this changing landscape, businesses should invest in employee training programs to equip their workforce with skills that complement automation technologies. Additionally, fostering a culture of innovation can help companies remain competitive. Staying abreast of emerging trends through comprehensive reports and studies will be crucial for strategic planning in an increasingly automated world.

Cost-Benefit Considerations for Investing in Robotic Systems

Investing in robotic systems is becoming increasingly viable for businesses looking to enhance productivity. According to a report by McKinsey, automation could raise productivity by up to 1.4 percent annually, significantly impacting operational efficiency. The initial costs of implementing robotic systems can be substantial, with average investments ranging from $20,000 to $100,000 depending on the complexity and functionality. However, the long-term benefits often outweigh these upfront expenses; companies can expect to see a return on investment (ROI) within three to five years through increased throughput and reduced labor costs.

Moreover, the global market for industrial robots is projected to reach $80 billion by 2025, indicating a robust trend towards automation across various sectors. A study by Deloitte reveals that businesses leveraging robotic systems report a 20-30% reduction in operational costs over time. The key to maximizing these benefits lies in strategic planning and insightful analysis of each solution's cost-benefit ratio. By carefully assessing their specific needs and aligning them with appropriate robotic technologies, companies can achieve not just savings but also enhanced agility in their operations.

10 Best Robot Machines for Efficient Automation in 2023

| Robot Type | Key Features | Cost (USD) | Estimated ROI (%) | Applications |

|---|---|---|---|---|

| Industrial Robot Arm | High precision, flexible programming | $50,000 | 30% | Manufacturing, Assembly |

| Collaborative Robot (Cobot) | Safe operation alongside humans | $35,000 | 25% | Packaging, Quality Inspection |

| Automated Guided Vehicle (AGV) | Route optimization, autonomous navigation | $40,000 | 20% | Warehouse, Logistics |

| Service Robot | User-friendly interface, voice recognition | $25,000 | 15% | Hospitality, Retail |

| Drones | High mobility, aerial surveillance | $15,000 | 40% | Agriculture, Surveying |

| Robotic Welding System | Automated welding, high-speed | $60,000 | 35% | Automotive, Construction |

| Inspection Robot | 360-degree inspection, real-time data | $45,000 | 20% | Oil & Gas, Infrastructure |

| Pizza Making Robot | Innovative food preparation | $10,000 | 50% | Food Service |

| Parcel Sorting Robot | Fast sorting, space-efficient | $30,000 | 30% | Logistics, Shipping |

| Cleaning Robot | Autonomous cleaning, smart mapping | $5,000 | 45% | Commercial, Residential |

Related Posts

-

Unlocking Business Efficiency with Robotic Process Automation Software Insights from Recent Industry Trends

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

Understanding the Essence of Robotics: What Defines a Robot in Today’s Tech Landscape

-

What is Robotics and Automation and How It Transforms Industries Today

-

10 Surprising Ways Automation Machines are Transforming Small Businesses in 2023

-

Top 10 Benefits of Using Robotic Welders in Modern Manufacturing