2026 Best Robotics and Automation Trends to Watch?

In the rapidly changing world of robotics and automation, experts are focused on emerging trends. Jennifer Lee, a leading robotics engineer, states, “Innovation in automation is reshaping every industry.” This sentiment highlights the importance of understanding future movements in this field.

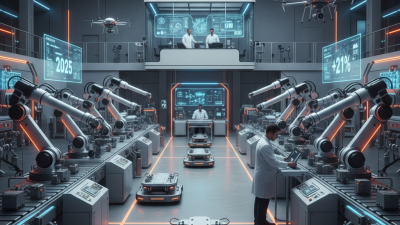

As we approach 2026, the landscape of robotics and automation is evolving at an unprecedented pace. Companies are integrating advanced AI and machine learning technologies. These developments are revolutionizing production lines and enhancing supply chain efficiency. However, there are also concerns about workforce impacts and the ethical implications of these technologies.

Industry leaders recognize that while automation boosts efficiency, it can also displace workers. Balancing technology with human employment remains a significant challenge. The future of robotics and automation is not just about advancement; it requires careful consideration of its broader effects on society.

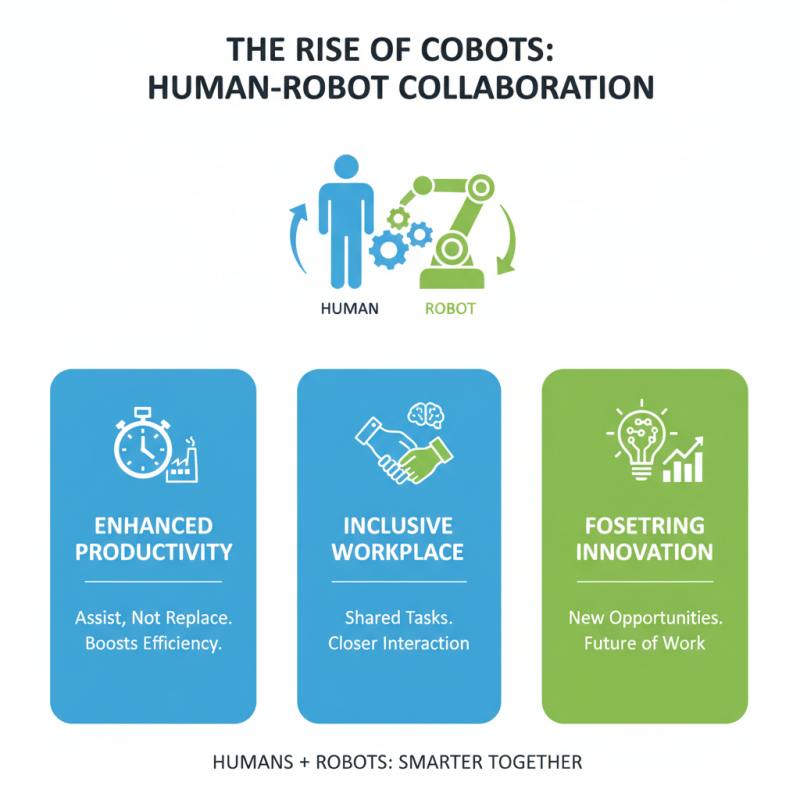

The Rise of Collaborative Robots: A Paradigm Shift in Automation

The rise of collaborative robots, or cobots, marks a significant shift in automation. These machines work alongside humans, enhancing productivity and efficiency. They are designed to assist rather than replace workers. This approach fosters a more inclusive workplace where humans and robots share tasks. The interaction is closer than ever, creating opportunities for innovation.

Cobots come with sensors and AI, allowing them to understand their environment. They can recognize human presence and adapt to changes. However, the integration is not without challenges. Safety regulations must evolve. Training programs need improvement. Workers sometimes feel threatened by automation. There is a need for a cultural shift in how we perceive these machines.

Industries are testing cobots for various applications. They handle repetitive tasks and increase precision. For example, they can work on assembly lines. But, the question arises: Will they always remain effective? Maintenance and upgrades will be crucial. Additionally, companies may face a skills gap with new technologies. Engaging workers in this evolution is essential for success.

Artificial Intelligence Integration: Enhancing Robotics Efficiency by 30%

In 2026, the integration of artificial intelligence (AI) into robotics will reshape industries. The forecast suggests a 30% increase in efficiency. Manufacturers will utilize AI algorithms to optimize robotics operations. This combination will lead to faster production times and reduced operational costs.

AI will enhance decision-making processes in robotics. For example, machine learning can help robots learn from their mistakes. They will adapt and improve tasks over time. However, not all applications succeed. Some AI systems may struggle with unexpected variables. This inconsistency raises questions about reliability.

Tips for businesses implementing AI in robotics: Start small. Test systems in controlled environments before full deployment. Constantly monitor performance. Gather data on failures and successes. Adjust strategies based on real-time feedback. Embrace the learning curve to maximize potential. This process can help mitigate risks and improve outcomes.

2026 Robotics and Automation Trends - Efficiency Enhancement through AI Integration

This chart displays the projected efficiency improvement in robotics and automation due to artificial intelligence integration from 2023 to 2026. Notably, a significant increase up to 30% is anticipated by 2026, demonstrating the transformative impact of AI on the industry.

Industry 4.0 and Its Impact on Manufacturing Automation Trends

Industry 4.0 is transforming manufacturing automation at an unprecedented rate. The adoption of smart technologies is driving efficiency and productivity. According to a report by McKinsey, companies embracing these technologies can increase productivity by up to 30%. This shift impacts not only processes but also workforce dynamics.

There are challenges to consider. Many workers feel anxious about job security. A survey from Deloitte found that 61% of employees are worried about automation replacing their roles. This underscores the need for retraining programs, which are often underfunded. Additionally, integration issues with legacy systems remain a significant barrier.

Data from the International Federation of Robotics indicates a 10% annual growth in industrial robot installations. However, the gap between advanced manufacturers and others is widening. Not all companies are equipped to implement these changes quickly. Those lagging behind risk losing competitive advantages.

2026 Best Robotics and Automation Trends to Watch

| Trend | Description | Expected Impact | Adoption Rate (%) |

|---|---|---|---|

| Collaborative Robots (Cobots) | Robots designed to work safely alongside humans, enhancing productivity. | Increased efficiency and reduced labor costs. | 55% |

| Artificial Intelligence in Automation | Leveraging AI for real-time analysis, predictive maintenance, and decision-making. | Improved accuracy and reduced downtime. | 75% |

| Autonomous Mobile Robots (AMRs) | Robots that can navigate and transport goods without human intervention. | Enhanced logistics and supply chain efficiency. | 65% |

| Edge Computing | Processing data near the source to reduce latency in real-time applications. | Faster decision-making and operation optimization. | 50% |

| Digital Twins in Manufacturing | Creating virtual models to simulate and optimize production processes. | Reduced costs and improved product lifecycle management. | 45% |

Advancements in Autonomous Vehicles and Their Implications for Logistics

The rise of autonomous vehicles is reshaping the logistics landscape. A recent report predicted that by 2026, the autonomous delivery market would reach $75 billion. This growth presents both opportunities and challenges for logistics companies. On one hand, autonomous vehicles can significantly reduce operational costs through efficient route planning. On the other hand, the technology still faces hurdles, such as regulatory approvals and public acceptance.

In urban environments, logistics firms are experimenting with small drones and self-driving vans. For instance, cities with heavy traffic could see a shift as over 30% of deliveries may convert to autonomous methods by 2025. However, safety concerns linger. Studies show that nearly 70% of consumers are wary of autonomous deliveries. Trust is crucial. Addressing these fears requires transparency and public engagement.

Moreover, there are environmental impacts to consider. Autonomous vehicles could reduce carbon emissions by 20% if widely adopted. Yet, the increased energy demand for these vehicles raises questions. Will the energy used for operating fleets outweigh the benefits? As companies dive deeper into automation, they must reflect on these issues. Balancing innovation and responsibility will be essential for a sustainable future in logistics.

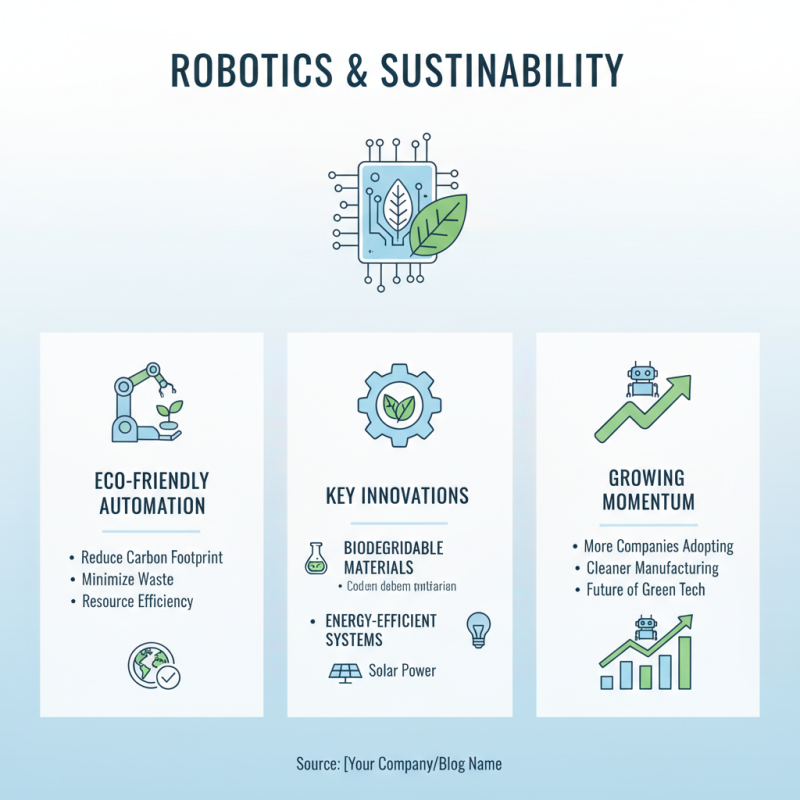

Sustainability in Robotics: Emerging Solutions for Eco-Friendly Automation

Sustainability in robotics is gaining momentum. More companies are focusing on eco-friendly automation solutions. These solutions aim to reduce carbon footprints and minimize waste. Innovations like biodegradable materials and energy-efficient systems are emerging. For example, some robots now use solar power. This helps lessen dependency on traditional energy sources.

However, challenges remain. Many robotic systems still rely on non-renewable resources. The development of sustainable robotics can be slow. Often, there is a gap between innovation and practical application. Not every solution is scalable or affordable. Companies may struggle to implement these eco-friendly options in real-time.

Efforts in recycling robotic components are also important. Encouraging a circular economy could lead to better sustainability practices. Collaboration among industries and researchers is vital for progress. Addressing these complexities will shape the future of robotics. So, while the trends are promising, they require continuous evaluation and improvement. We need to strive for a balance between technology and environmental responsibility.

Related Posts

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

How to Harness Robotics and Automation for Your Business Success?

-

What is Robotics and Automation and How It Transforms Industries Today

-

2026 How to Embrace Robot Technology for Future Innovations?

-

How to Implement Robotic Automation in Your Business for Maximum Efficiency

-

Top 10 Ways to Define a Robot and Its Impact on Society?