How to Choose and Implement a Fanuc Robot for Your Business Automation Needs

In today's rapidly evolving industrial landscape, automation stands out as a vital driver of efficiency and innovation for businesses across various sectors. Choosing the right automation technology can make a significant difference in enhancing productivity and streamlining operations. Among the myriad options available, the fanuc robot has emerged as a leading choice for companies looking to optimize their processes. With its versatility and advanced capabilities, the fanuc robot is designed to tackle a wide range of tasks, from assembly to packaging, making it an attractive solution for businesses seeking to remain competitive in a challenging market.

Implementing a fanuc robot involves a series of strategic decisions that can directly impact the success of automation initiatives. Understanding the specific needs of your operations is crucial in selecting the right model and features that align with your goals. Additionally, careful consideration of the integration process, maintenance requirements, and employee training are essential to ensure a smooth transition to an automated workflow. By evaluating these factors, you can effectively harness the power of a fanuc robot, transforming your business operations and paving the way for future growth. In this guide, we will explore the key aspects of choosing and implementing a fanuc robot, providing insights to help you navigate the complexities of automation in your business.

Understanding the Role of Fanuc Robots in Business Automation

In today's rapidly evolving industrial landscape, automation has become a pivotal element for businesses aiming to enhance efficiency and productivity. Fanuc robots, specifically designed for automation, play a crucial role by streamlining repetitive tasks, reducing operational costs, and increasing production rates. According to a report by the International Federation of Robotics, companies implementing industrial robots can boost their productivity by up to 30%, significantly impacting the bottom line.

One of the main advantages of utilizing automation through robotics is the ability to operate continuously without fatigue or downtime. A study by McKinsey & Company highlights that businesses can save approximately 20-40% on labor costs through the adoption of robotic systems. This not only allows for reallocation of human resources to more strategic tasks but also ensures that production runs at optimal capacity without compromising on quality. As companies seek to stay competitive, understanding the integration of automation solutions, particularly through advanced robotics, is vital for long-term success.

Assessing Your Automation Needs: Key Factors for Selection

Assessing your automation needs is crucial when selecting a robot for your business. One of the primary factors to consider is the specific tasks the robot will perform. Different robots are designed to handle various applications, whether it's assembly, packaging, or welding. Understanding your production processes and identifying repetitive tasks that could benefit from automation can streamline your selection process. Additionally, consider the payload capacity and precision needed for each task, as these will heavily influence the type of robot best suited for your operations.

Another key factor is the integration capabilities of the robot within your existing systems. Ensure that the robot can seamlessly connect with your current machinery and software to avoid any disruptions in workflow. Assessing the flexibility of the robot is also essential; a versatile robot that can be reprogrammed or adapted for multiple tasks can provide significant long-term value for your business. Moreover, consider the available support and training resources, as these can greatly affect how quickly your team can become proficient in utilizing the new automation technology. Investing time in thoroughly evaluating these factors will lead to a more successful implementation of automation in your business.

Evaluating Fanuc Robot Models and Specifications for Optimal Fit

When evaluating robot models and specifications for your business automation needs, it’s crucial to assess the operational requirements and the specific tasks the robot will perform. Different models come with varying payload capacities, reach, and degrees of freedom, which directly impact their suitability for different applications. For example, if your production line demands high precision and speed, selecting a robot with advanced motion control and positioning capabilities is essential. Ensuring the robot can integrate seamlessly with your existing systems is another key consideration.

Tips: Always create a comprehensive checklist of your automation needs, including factors like weight handling, workspace dimensions, and cycle time. Engaging in hands-on demonstrations or simulations can provide valuable insight into how a particular robot model performs in real-world scenarios.

Another important aspect to consider is the support and training provided by the manufacturer. Look for models that offer easily accessible technical support, and consider the availability of training programs for your team. Familiarizing your staff with the robot’s operation and programming can dramatically reduce downtime and increase productivity. Evaluate the long-term implications of adopting a specific robot model, from maintenance requirements to potential scalability as your business grows.

Tips: Involve your engineering team early in the selection process to ensure the chosen robot aligns with both current and future operational strategies.

Integrating Fanuc Robots into Existing Production Lines

Integrating robots into existing production lines can significantly enhance efficiency and productivity. When considering the addition of automation, it’s essential to assess how the new robotic systems will interact with current machinery and workflows. Start by mapping out the processes that require improvement and identifying the specific tasks that a robot could handle, whether it’s material handling, assembly, or quality inspection. This assessment will not only clarify your automation goals but also ensure that you select the right type of robot for your business needs.

Tips: Ensure thorough communication with your production teams during this integration phase. Their insights about existing workflows can reveal potential challenges and opportunities that may not be immediately apparent. It’s also crucial to provide adequate training for your staff to work alongside the new robotic systems, promoting a seamless transition and maximizing the effectiveness of automation.

Another consideration is the adaptability of the robots to your production line's layout and flow. Modifications might be necessary to accommodate the robot and facilitate its operation. Conducting trials and simulations can be beneficial. They allow you to visualize the integration process and make any necessary adjustments before full implementation, ensuring minimal disruptions to ongoing production activities.

Tips: Consider investing in scalable robotics that can easily be reprogrammed or reconfigured. This flexibility can save time and costs down the line as your production needs evolve.

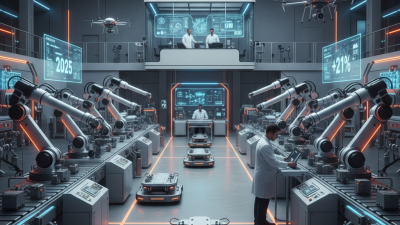

Measuring ROI and Performance Post-Implementation of Fanuc Robots

Measuring ROI and performance after the implementation of robotic automation is crucial for businesses looking to enhance efficiency and productivity. According to a study by the Association for Advancing Automation, 90% of manufacturers reported that automation has led to improved productivity levels, often translating to higher returns on investment (ROI). Companies typically see an ROI ranging from 10% to 30% within the first year of deploying robotic systems, driven by reduced labor costs and increased operational speed. By setting clear performance metrics, businesses can monitor key indicators such as cycle time, throughput, and defect rates to gauge the effectiveness of their automation solutions.

Post-implementation analysis also involves evaluating the impact on workforce dynamics and overall productivity. Research from the McKinsey Global Institute indicates that companies that adopt automation technologies can increase their productivity by up to 1.4 times compared to their non-automated counterparts. This significant shift can empower employees to focus on higher-value tasks, fostering innovation and job satisfaction. Furthermore, examining customer satisfaction metrics post-implementation can highlight how automation improves service delivery and enhances responsiveness, ultimately driving business growth and competitive advantage in the marketplace.

How to Choose and Implement a Fanuc Robot for Your Business Automation Needs - Measuring ROI and Performance Post-Implementation of Fanuc Robots

| Metric | Pre-Implementation | Post-Implementation | ROI (%) |

|---|---|---|---|

| Production Output (Units/Hour) | 50 | 120 | 140% |

| Labor Costs ($/Hour) | $30 | $10 | -66.67% |

| Downtime (% of Time) | 20% | 5% | 75% |

| Defect Rate (%) | 8% | 2% | 75% |

| Initial Investment ($) | N/A | $100,000 | N/A |

Related Posts

-

How to Implement Robotic Automation in Your Business for Maximum Efficiency

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

What is Robotics and Automation and How It Transforms Industries Today

-

Top 5 Reasons Why Fanuc Robots Lead the Automation Industry with 20 Percent Market Share

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

Best 10 Fanuc Robots for Automation in 2023