How to Choose the Right Material Handling Robots for Your Warehouse Needs?

Choosing the right material handling robots for your warehouse can significantly impact efficiency and productivity. John Smith, an industry expert in automation, once said, "Selecting the right robot can make the difference between success and failure." This underscores the importance of understanding your specific needs.

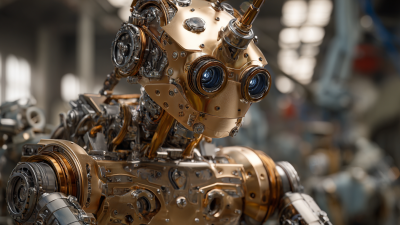

Material handling robots come in various shapes and sizes. They range from autonomous mobile robots to robotic arms. Each type offers unique advantages suited to different tasks. For instance, some excel in transporting goods, while others are designed for picking and packing. Your warehouse's layout and workflow greatly influence your decision.

However, the selection process is not always straightforward. Some may rush into choosing without a deep analysis. It's essential to evaluate your current operations. Identify the bottlenecks and areas for improvement. Remember, every warehouse is unique, and there is no one-size-fits-all solution in material handling robots. Reflecting on these factors will help you make an informed choice.

Understanding the Different Types of Material Handling Robots Available

When selecting material handling robots for your warehouse, it’s essential to understand the types available. Automated Guided Vehicles (AGVs) are popular. They navigate without human intervention, reducing labor costs. They can transport materials from one area to another. However, they require consistent floor markings and may not handle sudden obstacles well.

Another type is Autonomous Mobile Robots (AMRs). Unlike AGVs, AMRs are more flexible. They adapt to changing environments and dynamic paths. This means they can improve efficiency over time. Yet, the technology can be complex. Not every warehouse is ready for such advanced systems.

Robotic arms are also a choice for warehouses. They handle repetitive tasks like picking and placing. They may increase speed but involve a hefty upfront investment. Also, they often need specific setup configurations. Choosing the right robot depends on your specific needs and challenges. Balancing costs and efficiency is crucial. Each type has its pros and cons. Understanding these can help achieve greater productivity.

Evaluating Your Warehouse Workflow and Space Requirements

When evaluating your warehouse workflow and space requirements, start by mapping the current layout. Identify high-traffic areas where movement is frequent. Look for bottlenecks that slow down operations. This analysis reveals where robots can help improve efficiency.

Consider your specific needs. Are you moving heavy goods or smaller items? Different sizes and weights require different robotic solutions. Measure your aisles and storage areas too. Will the robots fit? A robot may work well in one space but become ineffective in another. Think about future growth; your needs might change.

Also, keep in mind the training aspect. Employees need to know how to work with new robots. If they're not onboard, the system may not operate smoothly. Remember, it takes time for everyone to adapt to new technology. If your team is not ready, it can lead to frustration and inefficiency. Balancing technology with human factors is crucial for success.

How to Choose the Right Material Handling Robots for Your Warehouse Needs?

| Robot Type | Load Capacity (kg) | Height (cm) | Operating Speed (m/s) | Battery Life (hours) | Ideal Environment | Cost Range ($) |

|---|---|---|---|---|---|---|

| Autonomous Mobile Robot | 500 | 90 | 1.5 | 8 | Indoor | 10,000 - 15,000 |

| Automated Guided Vehicle | 800 | 70 | 1.2 | 12 | Indoor | 20,000 - 30,000 |

| Robotic Arms | 200 | 150 | 0.8 | 10 | Indoor & Controlled Environment | 30,000 - 50,000 |

| Automated Pallet Jack | 1000 | 100 | 1.0 | 6 | Indoor | 15,000 - 25,000 |

| Picking Robot | 50 | 120 | 1.3 | 5 | Indoor | 25,000 - 35,000 |

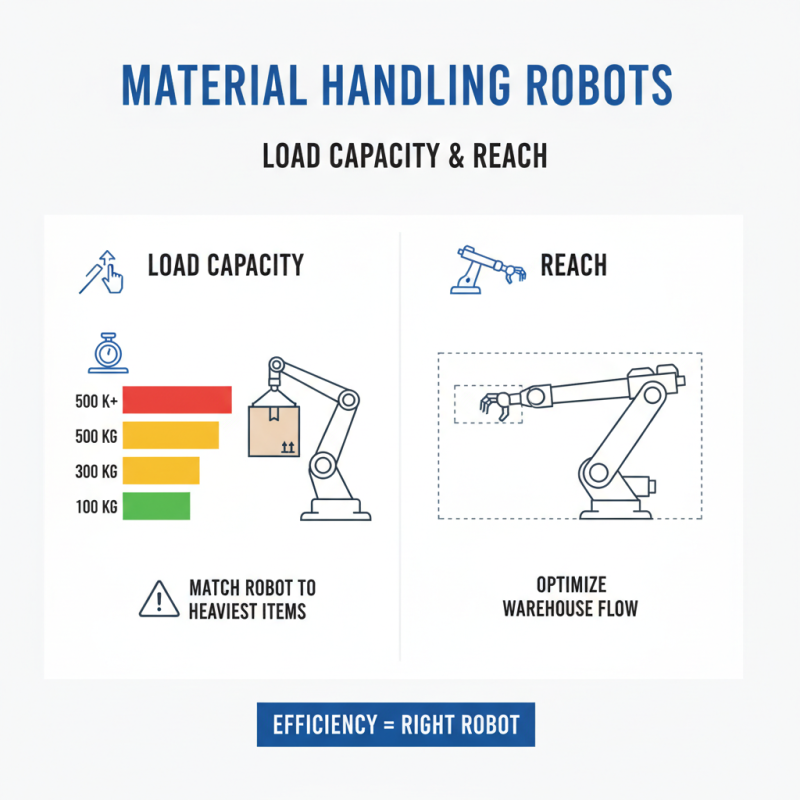

Assessing Load Capacity and Reach for Optimal Robot Selection

Choosing the right material handling robots involves careful consideration of load capacity and reach. The load capacity of robots typically ranges from 100 kg to 500 kg. Selecting a robot with insufficient capacity can lead to performance issues and potential damage. Many warehouses experience efficiency drops when their robots can’t handle expected loads. The right robot must align with the heaviest items in your inventory.

Reach is equally critical. A robot with an inadequate reach may struggle to access necessary areas. For instance, a robot that can only lift to 1.5 meters might not suffice in a high-storage facility. An optimal choice will extend the robot's reach where needed while maintaining stability.

**Tip:** Assess your maximum pallet heights and narrow aisles before choosing a robot.

Understanding your operation’s layout is vital. You may find some robots work well in open areas but struggle in tight spaces. Test different models in your actual environment before making a final decision. Avoid common errors by considering both load and reach thoroughly.

**Tip:** Consult industry reports for insights on efficiency gains from improved reach and capacity.

Gauge how often you need to move heavy loads. Consider fluctuations in inventory and peak seasons. A robot that works perfectly under normal conditions may falter during high-demand periods. The key is to find balance.

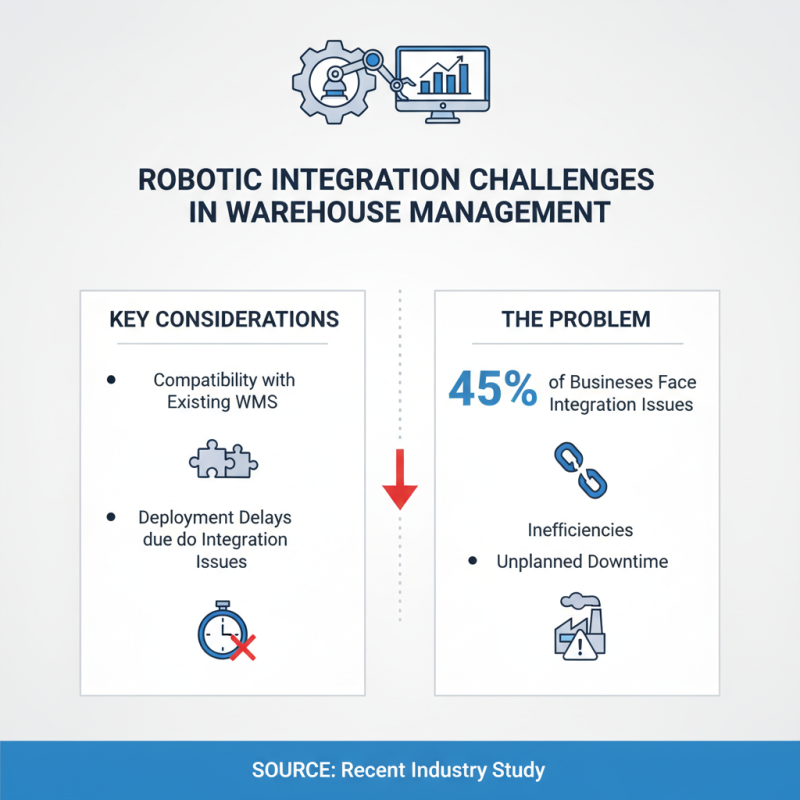

Considering Integration with Existing Warehouse Management Systems

When selecting material handling robots, consider how they fit with your existing warehouse management systems (WMS). Many companies report that integration challenges can delay deployment. According to a recent study, 45% of businesses face integration issues when implementing new robotic systems. This can lead to inefficiencies and unintended downtime.

It's crucial to assess the compatibility of the robot's software with your WMS. Some systems may require extensive customization. Data from industry reports indicates that companies investing in customizable robots see a 30% reduction in operational issues over time. Ensure you clarify these requirements before purchase.

**Tip:** Research your WMS capabilities. Identify any potential gaps or required updates. This could save time and resources.

Another consideration is data flow between the robot and your existing systems. Streamlined communication is essential for maximizing efficiency. Ensure that real-time data sharing is smooth. An inefficient data exchange may result in incorrect inventory counts and delays.

**Tip:** Conduct a pilot test with your chosen system. Monitor how well it communicates with your WMS. This early step can highlight issues that need addressing.

Investing time upfront into integration planning can prevent costly delays. Always consider these aspects. It helps to align warehouse operations effectively.

Budgeting and Maintenance Factors for Long-term Robot Investment

Choosing the right material handling robots for your warehouse is crucial. Budgeting is a significant aspect when investing in automation solutions. Many businesses overlook the hidden costs associated with robots. Initial purchase price is only the beginning. Maintenance and repair expenses can add up over time. It's vital to assess the long-term costs of ownership.

Consider how often your robot will be in use. If the workload is high, you may end up spending more time on repairs. Some robots may require specialized technicians for maintenance. This can lead to unexpected expenses. It’s important to evaluate the reliability of the robot. Evaluate how long it takes to train staff on new systems. Training can often be a time-consuming process. Factor in downtime during this phase.

Additionally, think about replacement parts and availability. Will they be accessible when needed? Some robots need specific components that may not be readily available. This can lead to delays. A clearer understanding of your budget can improve decision-making. Keeping a reserve for unanticipated costs is wise. Balancing upfront investment with long-term sustainability is key. It's a complex but essential part of adapting to warehouse automation.

Material Handling Robots Cost Considerations

Related Posts

-

Why Are Material Handling Robots Essential for Modern Warehousing

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

Unlocking Business Efficiency with Robotic Process Automation Software Insights from Recent Industry Trends

-

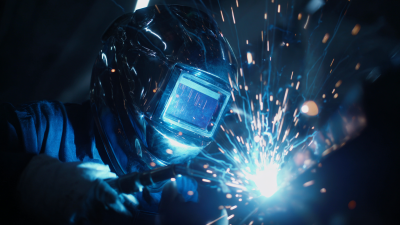

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency

-

Understand Robots in Digital World with Expert Tips for Beginners