How to Choose the Best Robotic Welder for Your Manufacturing Needs

Choosing the right robotic welder for your manufacturing needs can be a daunting task, especially with the wide variety of options available on the market. Robotic welders are essential tools in modern manufacturing, providing precision, efficiency, and consistency that manual welding often cannot match. As industries continue to evolve and demand higher production rates, the integration of robotic welding solutions has become increasingly important. However, selecting the most suitable robotic welder requires a careful evaluation of several factors, including the specific applications, material types, and production volumes involved.

Understanding your production requirements is the first step in the decision-making process. Different robotic welders are designed for various applications and materials, from simple spot welding to more complex arc welding techniques. It is crucial to assess the scale of your operations and the specific welding tasks that need to be accomplished. Moreover, the capabilities of the robotic welder, including the type of welding process it supports and its adaptability to different welding positions, play a significant role in ensuring that it meets your manufacturing needs effectively.

In conclusion, investing in a robotic welder is a strategic decision that can enhance productivity and quality in your manufacturing processes. By evaluating your unique requirements and understanding the features and functionalities of different robotic welders, you can select the best solution to optimize your operations and drive your business forward.

Understanding the Basics of Robotic Welding Technology

Robotic welding technology is a rapidly evolving field that plays a crucial role in modern manufacturing processes. At its core, robotic welding involves the use of automated machines to perform welding tasks, significantly enhancing precision and efficiency compared to manual methods. These robots are equipped with sophisticated sensors and programming capabilities, allowing them to execute repetitive welding operations with consistent quality. Understanding the fundamentals of this technology is essential for manufacturers looking to optimize their production lines.

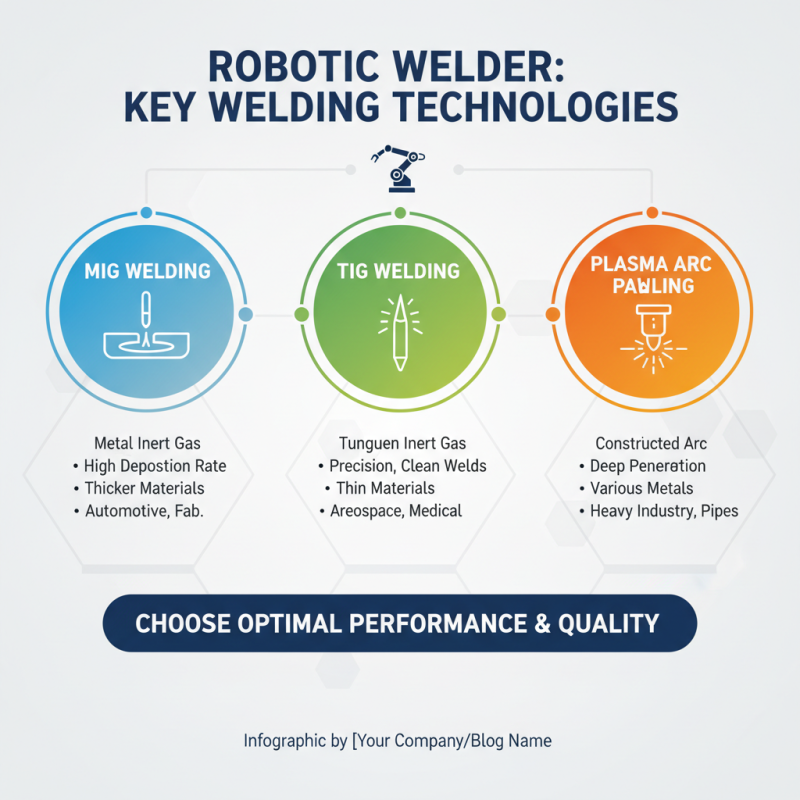

One of the key aspects of robotic welding is the different types of welding processes that can be automated, such as MIG, TIG, and spot welding. Each method has its own set of parameters and applications, making it important to assess the specific manufacturing needs before selecting a robotic welder. Additionally, advances in artificial intelligence and machine learning are allowing robots to adapt to various welding conditions, further improving operational versatility. Embracing robotic welding technology can lead to increased throughput, reduced labor costs, and enhanced safety in the workplace, positioning companies to remain competitive in an ever-changing industrial landscape.

Robotic Welding Technology Comparison

Identifying the Specific Needs of Your Manufacturing Process

When selecting the best robotic welder for a manufacturing process, it is crucial to first identify the specific needs of that process. Different manufacturing environments have unique requirements based on factors such as production volume, material types, and welding complexity. According to a 2021 report by the International Federation of Robotics, the adoption of industrial robots, including welders, has increased by 10% annually, highlighting a growing trend towards automation in manufacturing. This data suggests that understanding the particulars of your operations can significantly influence the choice of robotic welding technology.

For instance, the nature of the materials being welded plays a pivotal role in determining the appropriate robotic welder. Metals like aluminum require different techniques than steel or plastic. As highlighted in a study published in the "Journal of Manufacturing Processes," the right welding approach can improve efficiency by up to 25% when matched correctly to material types. Moreover, factors such as the desired precision and the welding environment, whether involving high-volume production runs or intricate, low-volume applications, should dictate the choice of technology. Integrating these considerations ensures that the selected robotic welder aligns with production goals, maximizing both output and quality.

Evaluating Key Features in Robotic Welders

When evaluating key features in robotic welders, one of the most critical aspects to consider is the welding technology employed. Different technologies such as MIG, TIG, and plasma arc welding offer various advantages depending on the materials and types of joints being welded. Understanding the specific requirements of your manufacturing process will help you choose a welder that can perform optimally, enhancing both efficiency and weld quality.

Another important feature to assess is the flexibility and programmability of the robotic welder. A welder that supports advanced programming options allows for easy adjustments to accommodate different tasks, making it invaluable for manufacturers focusing on varied production runs. Additionally, features like user-friendly interfaces and simulation capabilities can significantly reduce setup times and training requirements, increasing overall productivity in the workshop. For manufacturers looking to stay competitive, investing in a robotic welder with these key attributes can lead to significant long-term gains.

Comparing Different Brands and Models of Robotic Welders

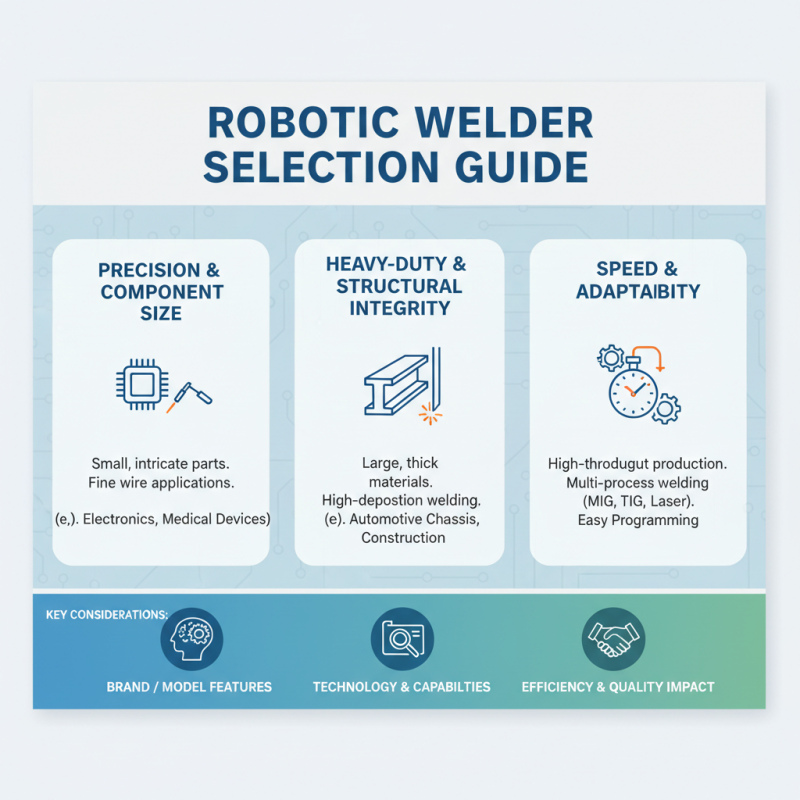

When it comes to selecting the right robotic welder for your manufacturing needs, understanding the differences between various brands and models is crucial. Different manufacturers offer a range of features, capabilities, and technologies that can significantly impact efficiency and quality. For instance, some robotic welders excel in precision for small components, while others are designed for heavy-duty applications requiring robust structural integrity. Additionally, factors such as speed, ease of programming, and adaptability to various welding processes can vary widely depending on the brand.

Moreover, the availability of customer support and service options also plays a vital role in the decision-making process. Some brands may provide extensive training resources and technical assistance, helping manufacturers to quickly optimize their welding operations. Comparing the specifications of different models, including payload capacity, reach, and integrated safety features, is essential to ensure that the selected robotic welder aligns well with specific production requirements. By carefully evaluating these aspects, manufacturers can make informed decisions that lead to improved productivity and reduced operational costs.

Budgeting for Your Robotic Welder Investment

When considering the investment in robotic welders, budgeting effectively is crucial to ensure a beneficial return on investment. According to a recent industry analysis, the average cost of a robotic welding system can range from $20,000 to $100,000, depending on the complexity and capabilities of the machine. This initial investment must be evaluated against the potential increase in productivity and quality, which can lead to significant long-term savings. A well-chosen robotic welder can reduce labor costs by up to 50% and improve welding speed by 30%, underscoring the importance of aligning your budget with your operational goals.

Tips: Before finalizing your budget, assess whether you need a standard or customized robotic welding system. Standard systems may suffice for repetitive tasks, while customized solutions can address specific manufacturing challenges. Additionally, consider the total cost of ownership, which includes maintenance, training for operators, and potential software upgrades. This holistic approach will provide a clearer picture of your long-term investment.

Furthermore, factor in the potential downtime associated with training and system integration. A well-planned implementation strategy can minimize disruptions and maximize your budget's effectiveness. Research shows that manufacturers who engage in thorough pre-purchase analysis can decrease installation time by up to 25%, leading to quicker returns. Allocating funds for expert consultation during the budgeting phase can significantly enhance your purchasing decision.

| Model | Type | Welding Process | Payload (kg) | Price ($) | Ideal Applications |

|---|---|---|---|---|---|

| Model A | Articulated | MIG/MAG | 20 | 30,000 | Automotive Parts |

| Model B | Cartesian | TIG | 15 | 22,000 | Metal Fabrication |

| Model C | Cylindrical | Spot | 10 | 18,000 | Electronics Assembly |

| Model D | Delta | Laser | 5 | 50,000 | High-Precision Tasks |

| Model E | Collaborative | Hybrid | 8 | 25,000 | Small Batch Production |

Related Posts

-

How to Choose the Right Robotic Welder for Your Manufacturing Needs

-

Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency

-

Top 10 Benefits of Using Robotic Welders in Modern Manufacturing

-

Best 10 Fanuc Robots for Automation in 2023

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

How to Implement Robotic Automation in Your Business for Maximum Efficiency