2026 How to Embrace Robot Technology for Future Innovations?

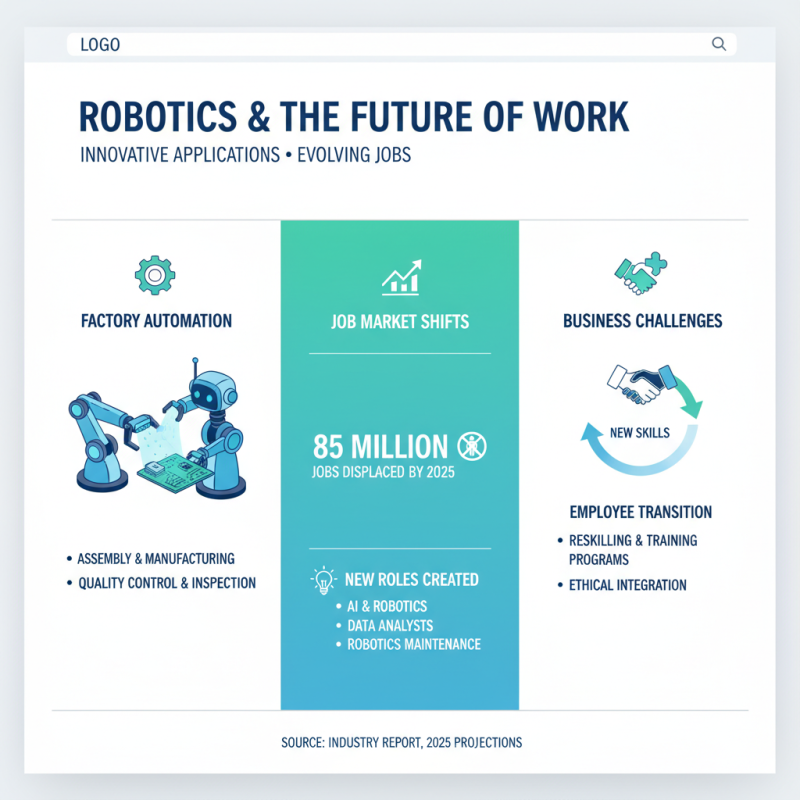

As industries evolve, embracing robot technology becomes essential for future innovations. The World Economic Forum reports that automation could replace 85 million jobs by 2025. Yet, this shift opens doors for new roles that require human oversight. Failing to adapt could leave companies trailing behind in an increasingly competitive market.

Experts highlight the need for strategic implementation of robot technology. Dr. Tom Reilly, a leader in robotic systems, emphasizes, "Incorporating robots is not just about efficiency; it’s about revolutionizing workflows." His insight resonates as businesses explore automation to enhance productivity. However, challenges remain. Workforce adaptation is critical, and resistance to change is common.

Robot technology should not only drive efficiency but also spark innovation. Companies need to address potential ethical dilemmas and job displacement concerns. Engaging employees in the transition can foster a culture of acceptance. This journey requires reflection on local workforce capabilities and resource allocation. Ignoring these aspects may hinder success in a tech-driven future.

Understanding Robot Technology: Key Concepts and Definitions

Robot technology is reshaping our future. It includes various fields, like artificial intelligence, robotics, and automation. These components work together to create more efficient systems. Understanding these concepts is crucial for future innovations.

Robotics focuses on the design and usage of robots. These machines can perform tasks ranging from manufacturing to healthcare. Automation, on the other hand, refers to using technology to carry out processes with minimal human input. This can improve speed and accuracy in various sectors.

However, integrating robot technology into our lives poses challenges. There are issues related to job displacement. Not everyone may be ready to embrace these changes. Society must think critically about these impacts. Continuous dialogue is needed to address concerns about privacy and ethics. Engaging with these topics helps prepare us for a world shaped by robotics.

The Current State of Robot Technology in Various Industries

Robot technology is making waves across various industries. The manufacturing sector has seen a significant shift. According to a report from the International Federation of Robotics, robot installations reached a record 3 million units in 2020. This growth reflects the industry's push for automation. However, despite this progress, many companies struggle to integrate these technologies effectively.

In healthcare, robots are increasingly used for surgeries and patient care. A study by Deloitte found that robotic surgery systems could reduce recovery times by 20%. Yet, challenges remain. There are concerns about the cost of deploying robotic systems in hospitals. Training staff to work with these technologies is another hurdle many face. A survey revealed that 40% of healthcare professionals feel unprepared for this transition.

The logistics sector is also evolving. The use of autonomous vehicles and drones is on the rise. Reports indicate that this trend could lead to a 25% decrease in delivery times. Still, deploying such technology is not without its issues. Regulatory frameworks are lagging, creating uncertainty for companies looking to innovate. Embracing robot technology requires addressing these gaps while maximizing potential benefits.

2026 How to Embrace Robot Technology for Future Innovations? - The Current State of Robot Technology in Various Industries

| Industry | Current Robot Applications | Future Trends (2026) | Potential Impact |

|---|---|---|---|

| Manufacturing | Automated assembly lines, welding robots | Collaborative robots (cobots), AI-driven analytics | Increased productivity, reduced labor costs |

| Healthcare | Surgical robots, robotic prosthetics | Telehealth robots, AI diagnostics | Enhanced patient care, improved surgical precision |

| Agriculture | Autonomous tractors, robotic harvesters | Precision agriculture, drones for monitoring | Lower resource usage, increased crop yields |

| Retail | Inventory management robots, self-checkout kiosks | Customer service robots, AI-driven personalization | Enhanced shopping experience, streamlined operations |

| Logistics | Automated warehouses, delivery drones | Smart logistics, real-time tracking with AI | Faster delivery times, cost reductions |

Innovative Applications of Robots in Business and Daily Life

Innovative applications of robots are revolutionizing both business and daily life. In factories, robots automate tasks like assembly and quality checking. According to a recent industry report, about 85 million jobs may be displaced by automation by 2025. However, this trend also creates opportunities for new roles, requiring workers to adapt and reskill. Businesses face the challenge of ensuring a smooth transition for employees.

In daily life, robots assist in various ways. Service robots are appearing in restaurants, cleaning homes, and aiding the elderly. A survey shows that nearly 30% of households now use some form of robotic assistance. Yet, skepticism exists regarding reliability and job security. Many people still worry about technology replacing human interaction. This concern raises questions about the ethical implications of widespread automation.

While the advances in robotic technology promise efficiency and innovation, gaps remain. For instance, robots often struggle with tasks requiring fine motor skills or emotional intelligence. This leaves room for human workers to shine. The future of robotics will depend on balancing efficiency with genuine human connection.

Strategies for Integrating Robots into Existing Systems and Processes

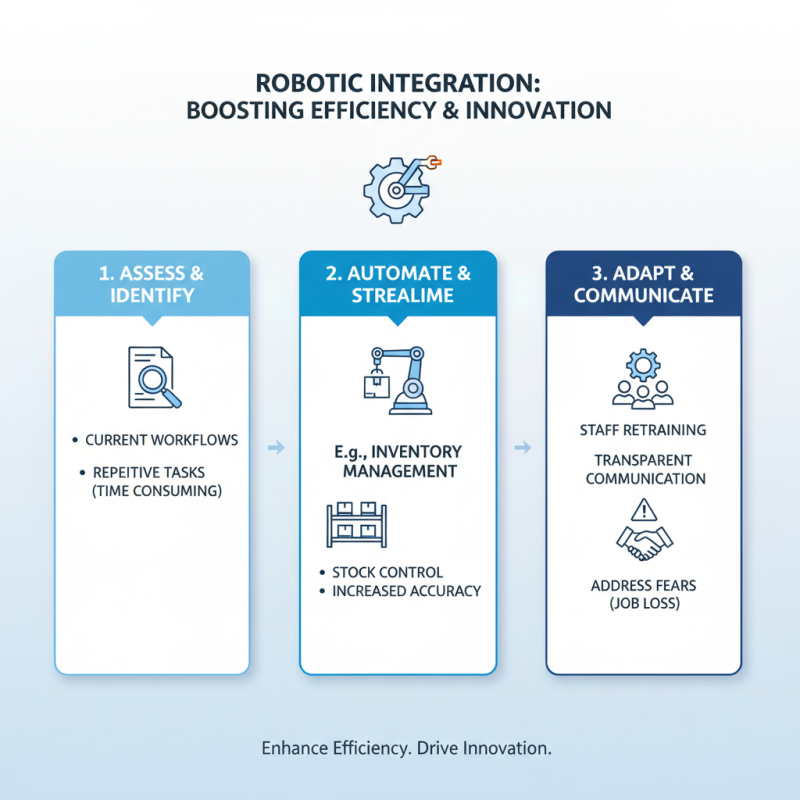

Integrating robots into existing systems can enhance efficiency and innovation. Start by assessing current workflows. Identify repetitive tasks that consume time. These are prime candidates for automation. For example, using robots in inventory management can streamline stock control. This shift often requires retraining staff. It is important to communicate changes clearly. Employees may resist new technologies due to fears of job loss.

Another strategy is to pilot small-scale projects. Testing robots in one area allows for adjustments before full implementation. Collect data during this phase. Analyze how robots impact productivity and employee satisfaction. It's essential to be prepared for unexpected challenges. Robots may not always function as intended. Regular feedback from users helps in refining the integration process.

Collaboration between teams is vital. Engineers, managers, and operators should work together. Their insights can bridge gaps and improve synchronization. Embrace the learning curve involved. Every project will reveal areas for improvement. Continuous adaptation is key to fully realizing the potential of robotic technology.

Future Trends: Preparing for Advancements in Robotics and Automation

As we look toward the future, robotics and automation will significantly shape our world. Businesses must adapt to these advancements. In various sectors, robots will handle repetitive tasks efficiently. This can reduce human error while increasing productivity. However, the transition is not without challenges. Workers may feel threatened by the rise of machines.

To embrace robot technology, companies need to invest in training programs. Employees must learn how to collaborate with robots. Understanding automation is vital for job security. There can be resistance to change, along with fears about job loss. Open communication can help address these concerns. Companies should foster an environment of innovation and flexibility.

Moreover, continuous improvement is key. As technologies evolve, so should the strategies for integrating them. Successful adoption requires patience and reflection. Determining which tasks are suitable for automation can be perplexing. It’s essential to evaluate both the benefits and drawbacks of each implementation carefully. Embracing robotics is not just about using technology; it’s about reshaping our approach to work and creativity.

Trends in Robotics and Automation Innovations (2026)

This chart illustrates the projected advancements in various sectors impacted by robotics technology, showcasing the growth in adoption rates from 2023 to 2026.

Related Posts

-

What Does a Robotics Technician Do and How to Become One?

-

Top 5 Reasons Why Fanuc Robots Lead the Automation Industry with 20 Percent Market Share

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

What is Robotics and Automation and How It Transforms Industries Today

-

10 Best Robot Machines for Efficient Automation in 2023

-

How to Implement Robotic Automation in Your Business for Maximum Efficiency