10 Essential Tips for Choosing Robotic Welding Systems for Your Business

In today's competitive manufacturing landscape, the integration of robotic welding systems has become pivotal for businesses aiming to enhance productivity and efficiency. As noted by Dr. Emily Carter, an esteemed expert in automation technology, "The right robotic welding systems can transform a company's operational capabilities, optimizing both time and quality." With the industry evolving rapidly, choosing the appropriate system requires careful consideration of various critical factors.

This article outlines ten essential tips that will guide you through the selection process of robotic welding systems tailored to meet your business needs. From assessing the scope of your welding projects to understanding the technological advancements available, these insights will empower you to make informed decisions. As companies look to adopt innovative solutions, understanding the nuances of robotic welding systems will not only streamline operations but also bolster your competitive edge in the market.

Understanding Robotic Welding Systems: Key Features and Benefits

Robotic welding systems have transformed the manufacturing landscape by offering precision, efficiency, and enhanced quality in welding processes. These systems often feature advanced technology such as programmable logic controllers (PLCs) and high-performance welding heads, which allow for automated, consistent, and high-quality welds. Understanding these key features is essential for businesses looking to invest in robotic welding. This includes the ability to handle diverse materials and thicknesses, adjust welding parameters on the fly, and integrate seamlessly with existing production lines.

In addition to their technical capabilities, robotic welding systems provide significant benefits that can bolster productivity and minimize operational costs. By automating repetitive welding tasks, businesses can reduce labor expenses and increase throughput, thereby improving overall efficiency. Furthermore, with enhanced precision, these systems lower the risk of human error, resulting in fewer defective products and reduced material waste.

The ability to monitor and collect data through advanced software also enables companies to make informed decisions and optimize production processes. Understanding these features and benefits is crucial for businesses to make informed decisions when selecting a robotic welding system that meets their specific needs and improves their competitive edge in the market.

Evaluating Your Business Needs for Robotic Welding Implementation

When considering the implementation of robotic welding systems, it is crucial to evaluate the unique needs of your business. A thorough needs assessment not only ensures a successful integration but also maximizes return on investment. According to industry studies, companies that carefully assess their requirements before investing in automation can experience up to 30% higher productivity rates. Take the time to analyze your current production processes, identifying areas where robotic welding can enhance efficiency, consistency, and quality control.

One essential tip is to consider the scale of your operations. For smaller businesses, a compact robotic welding solution may suffice, while larger enterprises may need more complex systems capable of handling higher volumes. Additionally, assess the types of welding materials and techniques your operations require. Reports indicate that businesses investing in multi-process robotic welders see up to a 40% reduction in rework and scrap rates, emphasizing the importance of compatibility with your existing processes.

Furthermore, delve into your workforce capabilities. According to a recent survey, nearly 60% of manufacturers cite the skill gap as a barrier to adopting advanced technologies like robotics. Providing training for existing employees can ease the transition and ensure they can effectively operate and maintain the new systems. Balancing operational needs with workforce capabilities will pave the way for a smooth implementation of robotic welding in your business.

Analyzing Cost-Effectiveness: ROI of Robotic Welding Systems

When evaluating the cost-effectiveness of robotic welding systems, Return on Investment (ROI) becomes a critical metric. According to a report from the International Federation of Robotics, companies that adopt automated welding solutions can experience productivity increments of up to 50%. This surge in efficiency often translates to significant savings in operational costs, as the integration of robotics can decrease the time spent on manual welding and reduce the likelihood of defects, which typically incur further costs in rework and material waste.

Furthermore, the initial investment in robotic welding technology can be recouped within two to three years, depending on the scale of production and existing labor costs. A study by the Welding Technology Institute reveals that the use of robotic systems can lower labor costs by approximately 30% while also providing consistent quality and speed that manual welding cannot match. This consistency enhances throughput and allows manufacturers to meet customer demands with greater agility, ultimately improving their competitiveness in the market. Thus, assessing the ROI of robotic welding systems is not merely about the upfront costs, but rather understanding the long-term financial benefits and operational efficiencies that these technologies can unlock for businesses.

ROI Comparison of Robotic Welding Systems

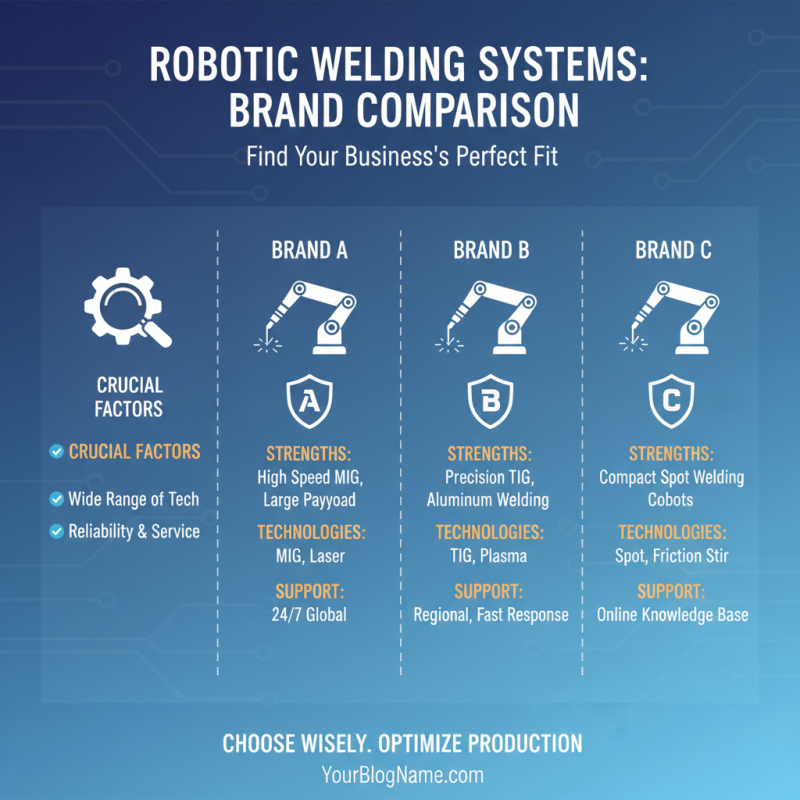

Comparing Major Brands and Manufacturers in the Robotic Welding Market

When evaluating robotic welding systems for your business, it's crucial to compare major brands and manufacturers in the market to find the right fit. Each brand has its own unique strengths and capabilities, which can significantly influence operational efficiency and the quality of finished products. Look for manufacturers that offer a wide range of welding technologies, such as MIG, TIG, or spot welding, as this versatility allows for greater adaptability to various project requirements. Additionally, consider the reputation of each brand for reliability and service support, as these factors can greatly impact your long-term satisfaction and productivity.

Another critical aspect is the availability of customizable solutions. Many leading manufacturers understand that no two businesses are alike, so they provide tailored systems to meet specific welding needs. Comparing the customization options offered by different brands can help you ensure that the welding system you choose aligns closely with your operational processes. Furthermore, evaluating the ease of integration with existing equipment and the scalability of the robotic systems is essential for future growth. Effective comparisons will enable you to select a robotic welding solution that optimizes performance while accommodating the evolving demands of your industry.

Assessing Safety Standards and Compliance for Robotic Welding Operations

When evaluating robotic welding systems for your business, one of the paramount considerations is adherence to safety standards and compliance regulations. According to the American National Standards Institute (ANSI), approximately 85% of workplace injuries in welding operations can be traced back to safety protocol failures. Therefore, ensuring that the robotic welding systems you choose meet established safety standards, such as ANSI and ISO 10218, is crucial for protecting your workforce and minimizing liability.

Compliance assessments should also consider the specific safety features integrated into robotic welding systems. Reports from the International Institute of Welding indicate that systems equipped with advanced safety mechanisms, such as emergency shut-off controls and integrated laser scanners, can reduce accident rates by up to 40%. It is vital to thoroughly review the safety certifications provided by manufacturers and to ensure that any robotic welding operations align with OSHA regulations. By prioritizing these safety standards, businesses can create a safer working environment while enhancing operational efficiency and maintaining regulatory compliance.

10 Essential Tips for Choosing Robotic Welding Systems for Your Business - Assessing Safety Standards and Compliance for Robotic Welding Operations

| Tip No. | Tip Description | Safety Standards | Compliance Certifications | Recommended Practices |

|---|---|---|---|---|

| 1 | Evaluate the workspace environment for risk assessment. | ISO 10218 | CE, UL Certification | Conduct regular safety audits. |

| 2 | Select systems with advanced safety features. | ANSI/RIA R15.06 | ISO 9001 | Integrate emergency stop mechanisms. |

| 3 | Assess integration with existing systems. | CE Marking | RoHS Compliance | Ensure compatibility with current machinery. |

| 4 | Consider training requirements for operators. | ISO 15066 | MOL Certification | Provide comprehensive operator training. |

| 5 | Research the total cost of ownership (TCO). | NFPA 79 | API Spec Q1 | Analyze maintenance costs and lifecycle. |

| 6 | Investigate company reputation and support. | EN ISO 12100 | ISO 45001 | Check reviews and case studies. |

| 7 | Evaluate system flexibility and scalability. | ISO 13849 | ISO 19011 | Prioritize modular systems for future needs. |

| 8 | Understand the impact of automation on labor. | OSHA Regulations | C-SCP Certification | Engage workforce for smooth transitions. |

| 9 | Select reliable suppliers with robust service. | IEC 61508 | ISO 3834 | Establish long-term vendor relationships. |

| 10 | Plan for ongoing maintenance and updates. | EN ISO 14738 | NEMA Certification | Schedule regular maintenance checks. |

Related Posts

-

What is an Automation Machine? Understanding Its Importance and Applications

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

Revolutionizing Efficiency: How the Automation Industry is Expected to Surge by 30% by 2025

-

Top 10 Benefits of Using Robotic Welders in Modern Manufacturing

-

Top 10 Robotics Classes for Beginners to Master in 2023

-

Understanding the Essence of Robotics: What Defines a Robot in Today’s Tech Landscape