Exploring the Future of Automation Through Fanuc Robots Advancements in Technology

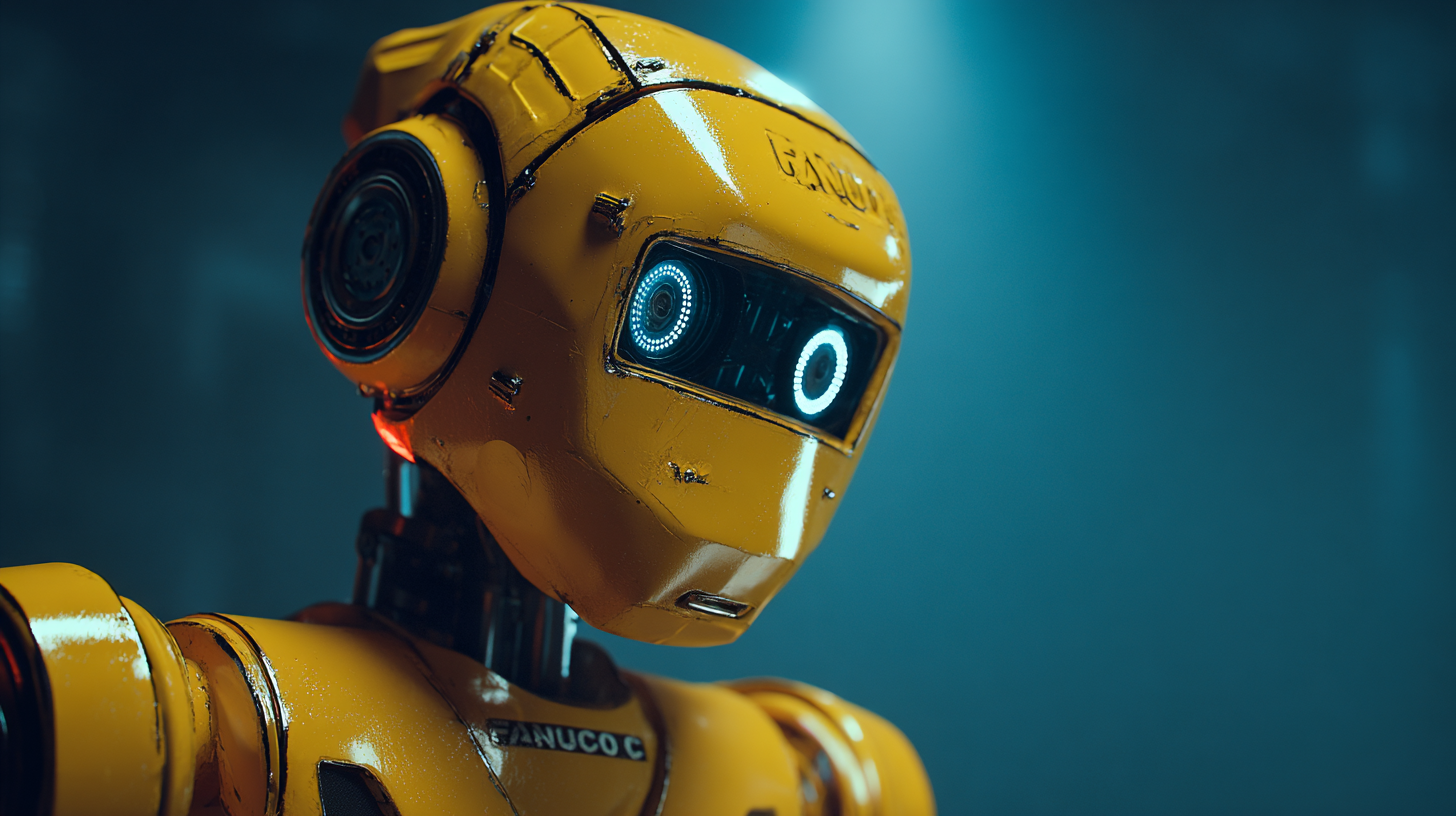

As we stand on the brink of a technological revolution, the advancements in automation are reshaping industries and redefining efficiency. Among the leading players in this transformative landscape is the Fanuc robot, a symbol of innovation and precision engineering. This exploration delves into how Fanuc robots are not merely tools but pivotal catalysts in advancing automation technology. With their ability to enhance productivity, ensure consistent quality, and adapt to complex tasks, Fanuc robots are setting new standards for operational excellence.

The future of automation is not just about integrating robots into existing systems; it is about rethinking how we use these intelligent machines to drive progress across various sectors. As we investigate the "why" behind these advancements, we uncover the potential of Fanuc robots to revolutionize workflows, create new job opportunities, and challenge our understanding of what is possible in automation.

Understanding the Basics of Fanuc Robot Technologies and Their Applications

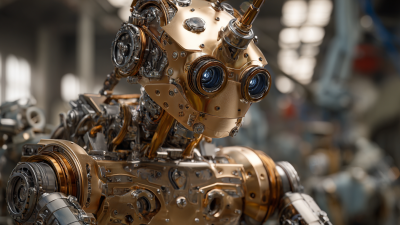

Fanuc robots represent a significant leap in automation technology, combining advanced precision and versatility to enhance industrial productivity. Understanding the basics of Fanuc robot technologies helps illuminate their diverse applications across various sectors. Fanuc offers a wide range of robotic solutions, including collaborative robots (cobots), articulated robots, and SCARA robots, each designed to tackle specific tasks. For instance, according to a report by the International Federation of Robotics (IFR), the global stock of operational industrial robots reached approximately 3 million units in 2021, with a notable portion attributed to manufacturers like Fanuc, which has established a robust presence in automotive, electronics, and logistics industries.

In practical terms, Fanuc robots are often noted for their ease of integration and programming flexibility, which allows companies to quickly adapt to changing production demands. Data from a 2022 market analysis by Statista indicates that manufacturers adopting automation technologies have seen productivity increases of up to 30%. With Fanuc’s comprehensive training programs and support resources, companies can harness these technologies efficiently. Moreover, the growing trend towards Industry 4.0 drives the adoption of IoT-enabled robots, enabling real-time data analytics and remote monitoring, ultimately paving the way for smarter manufacturing processes.

Key Innovations in Automation: How Fanuc Robots are Shaping Industries

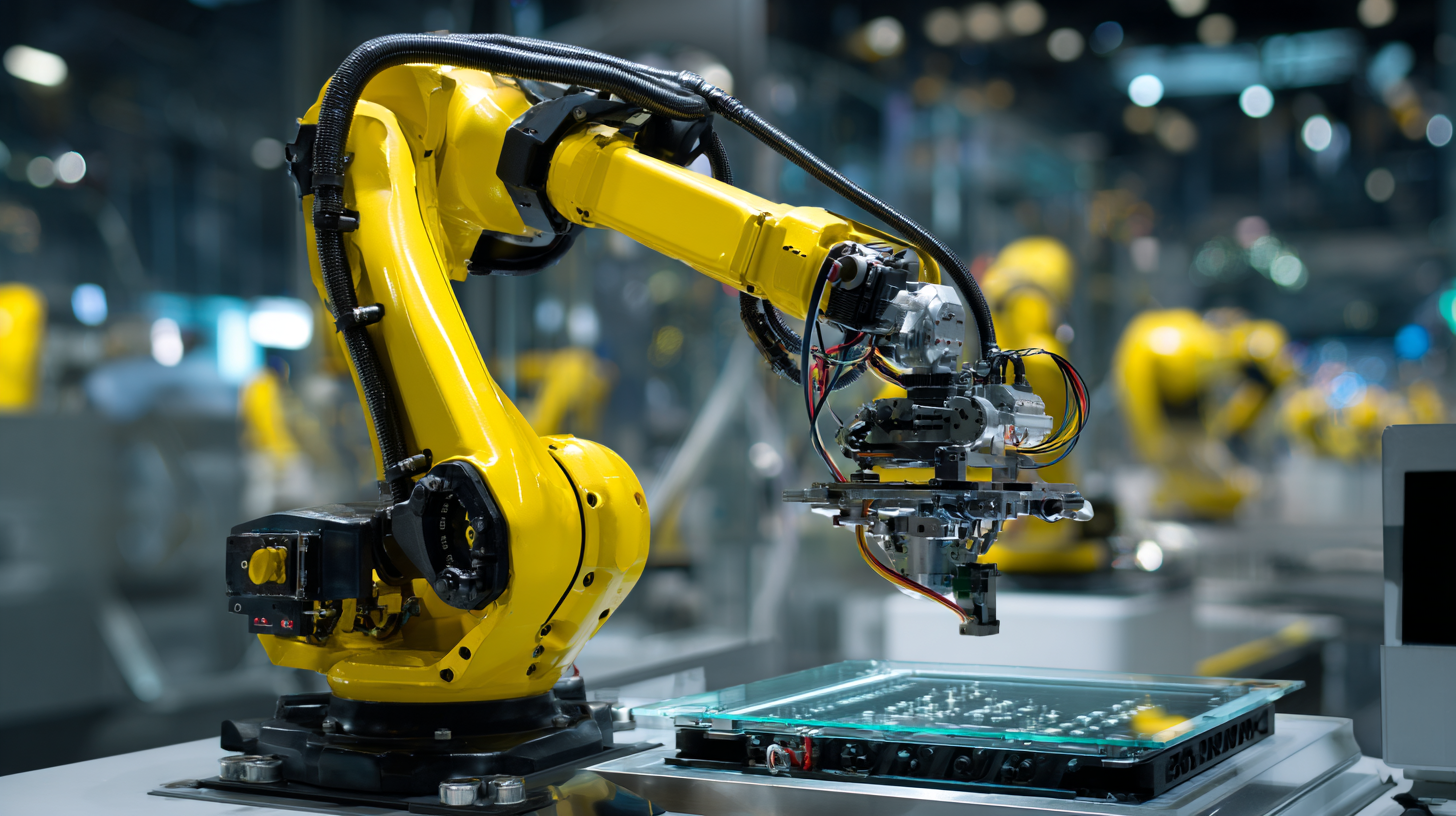

The realm of automation is undergoing a remarkable transformation, largely driven by innovations in Fanuc robots. These sophisticated machines are not only enhancing productivity but also redefining operational efficiency across various industries. From automotive manufacturing to electronics assembly, Fanuc robots are equipped with cutting-edge technology that enables them to perform complex tasks with precision and speed. Their adaptability allows businesses to integrate automation seamlessly, reducing downtime and increasing output.

Tips for integrating Fanuc robots into your operations include conducting a thorough assessment of your production needs and workflow. This will help in selecting the right models that align with your objectives. Additionally, investing in training for your workforce can maximize the potential of these robots, ensuring that employees are equipped to manage and maintain the technology effectively. Embracing this shift towards automation not only optimizes processes but also allows for a safer work environment as robots take on hazardous tasks.

Moreover, advancements such as artificial intelligence integration and enhanced communication capabilities are setting Fanuc robots apart. These innovations allow for real-time data analysis and predictive maintenance, enabling industries to respond proactively to issues before they escalate. As technology continues to evolve, businesses that adopt these automated solutions can look forward to substantial competitive advantages in their respective markets.

Integrating Fanuc Robots into Existing Production Systems for Maximum Efficiency

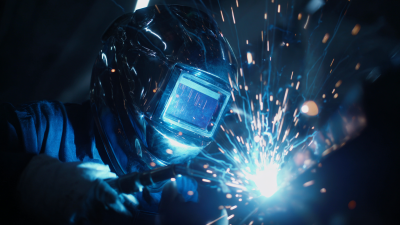

The integration of advanced robotic systems into existing production lines is crucial for achieving maximum efficiency in today's fast-paced industrial environment. As companies look to enhance their operational capabilities, the application of advanced automation technologies becomes increasingly essential. The implementation of sophisticated robotic solutions enables manufacturers to streamline processes, reduce error rates, and improve overall productivity. With the global robotic welding market projected to expand significantly in the coming years, businesses are encouraged to adopt these innovations to stay competitive.

Moreover, the rise of inspection robots highlights the growing importance of automation in quality control. This segment is expected to reach substantial market size, reflecting a booming demand for robotics that enhance precision and reliability in manufacturing processes. As industries evolve, the collaboration between human workers and robotic systems will not only optimize workflows but also transform the way products are manufactured and inspected, ultimately driving growth in various sectors. Embracing these advancements positions organizations to meet contemporary challenges while fostering a culture of continuous improvement.

Future Trends: What’s Next for Fanuc Robots and Automation Technologies

As we look to the future, the landscape of automation technologies is poised for remarkable transformation, particularly with the advancements in Fanuc robots. One of the most significant trends is the integration of artificial intelligence and machine learning into robotic systems. These advancements enable Fanuc robots to learn from their environments and optimize their tasks in real-time, leading to greater efficiency and precision in various applications, from manufacturing to logistics.

Another key trend is the increasing focus on collaboration between human workers and robots, known as cobots. Fanuc's development of safer, more intuitive robots facilitates seamless interactions on the factory floor. This shift not only enhances productivity but also allows human operators to focus on more complex tasks that require cognitive skills. Furthermore, the demand for flexible automation solutions is driving innovation, with Fanuc robots being designed for adaptability in dynamic environments, which is essential as industries strive for more responsive and customized production systems. The future of automation with Fanuc robots promises not only to enhance operational efficiency but also to redefine the roles of human workers in various sectors.

Navigating Challenges in Automation: Implementing Fanuc Robotics Successfully

As the automation landscape continues to evolve, implementing robotics successfully poses both opportunities and challenges for industries. Advanced robotics, exemplified by innovations in intelligent mobility, offer unprecedented capabilities in tasks ranging from manufacturing to healthcare. In settings like geriatric rehabilitation, the integration of robotics not only improves efficiency but also enhances the quality of care for individuals requiring assistance. These advancements urge organizations to navigate the complexities of incorporating such technologies into existing systems while maintaining a focus on user experience and operational efficacy.

Moreover, the rise of AI in industrial automation highlights the importance of predictive maintenance and streamlined operations, transforming traditional workflows into highly efficient processes. While the shift towards automation can be daunting, understanding the available solutions and strategic implementation can significantly contribute to overcoming these challenges. Companies that successfully leverage intelligent robotics not only gain a competitive edge but also drive innovation across their sectors. The future of automation heavily relies on this adaptability, as organizations harness the power of intelligent systems to foster growth and sustainability in an increasingly automated world.