How to Harness Robotics and Automation for Your Business Success?

In today's fast-paced business landscape, leveraging robotics and automation has become crucial for success. According to a McKinsey report, 45% of work activities can be automated using current technology. This statistic highlights the significant potential of integrating these technologies into operations. Experts like Dr. David Levy, a leader in robotics research, emphasize that "embracing robotics and automation is no longer optional; it’s a necessity for competitive survival."

Businesses are increasingly recognizing that robotics and automation can enhance efficiency and productivity. For instance, manufacturers have adopted automation systems that reduce labor costs by up to 30%. Retailers are also utilizing robotic solutions for inventory management, leading to faster restocking times. However, with such advancements comes an ongoing challenge: companies must thoughtfully implement these technologies to avoid workforce displacements.

Reflecting on the disadvantages is vital. While robotics and automation improve efficiency, they can spark concerns over job security. Balancing technology with human roles requires strategic planning. Companies must address these concerns while maximizing the benefits of robotics and automation to ensure sustainable growth.

Understanding Robotics and Automation in the Business Landscape

In today's business landscape, robotics and automation are revolutionizing operations. A recent report from McKinsey suggests that automation could increase productivity by up to 40% in various sectors. This potential is enticing for many companies. However, adopting these technologies is not without challenges.

Many businesses struggle with the initial investment costs. According to a Deloitte study, 58% of companies highlight financial concerns as a barrier to automation. Additionally, integrating new systems with existing processes can be complex. Change management is crucial. Employees may resist new technologies due to fear of job loss or unfamiliarity. This resistance can hinder progress.

Moreover, understanding the right areas for implementation is essential. Not all tasks benefit equally from robotics. It's vital to conduct a thorough assessment of workflows. The World Economic Forum predicts that automation could replace 85 million jobs by 2025. But it also emphasizes the creation of 97 million new roles. Balancing this transition is key. Hard choices lie ahead as businesses navigate this evolving landscape.

How to Harness Robotics and Automation for Your Business Success?

| Aspect | Description | Benefits | Challenges |

|---|---|---|---|

| Robotics in Manufacturing | Use of robots to automate repetitive manufacturing tasks. | Increased efficiency, reduced labor costs, improved precision. | High initial investment, need for skilled programming. |

| Automated Customer Service | Chatbots and automated response systems for customer inquiries. | 24/7 support, reduced wait times, lower costs. | Limited understanding of complex queries, potential frustration for customers. |

| Warehouse Automation | Use of automated guided vehicles (AGVs) and drones for inventory management. | Improved inventory accuracy, cost savings on labor. | Integration with existing systems, initial implementation hurdles. |

| Process Automation | Automating administrative tasks such as payroll and data entry. | Time savings, reduced human error, improved compliance. | Resistance to change, potential job displacement concerns. |

| Data Analytics Automation | Using automated tools for data analysis and reporting. | Faster insights, data-driven decision-making. | Data quality issues, need for advanced analytical skills. |

Identifying Business Areas for Robotics and Automation Implementation

Identifying the right areas for robotics and automation in your business is crucial. Start with repetitive tasks. These are often dull and time-consuming. Consider tasks like data entry, inventory management, or assembly line functions. Automating these can save time and reduce errors. Employees can focus on more creative roles. This shift can enhance overall productivity.

Next, look at customer service. Chatbots and automated systems can handle common inquiries. They provide instant responses, improving customer satisfaction. However, ensure these systems don’t lose the personal touch. Sometimes, robotic solutions can feel impersonal. Balancing efficiency and a human connection is key.

Consider the integration of automation in logistics. Automating shipping processes and warehouse management can streamline operations. But, adapting to new technologies presents challenges. Employee training is essential. Resistance to change can slow progress. Assessing your team's readiness is just as important as choosing the technology itself.

How Robotics and Automation Impact Different Business Areas

Selecting the Right Robotics and Automation Tools for Your Needs

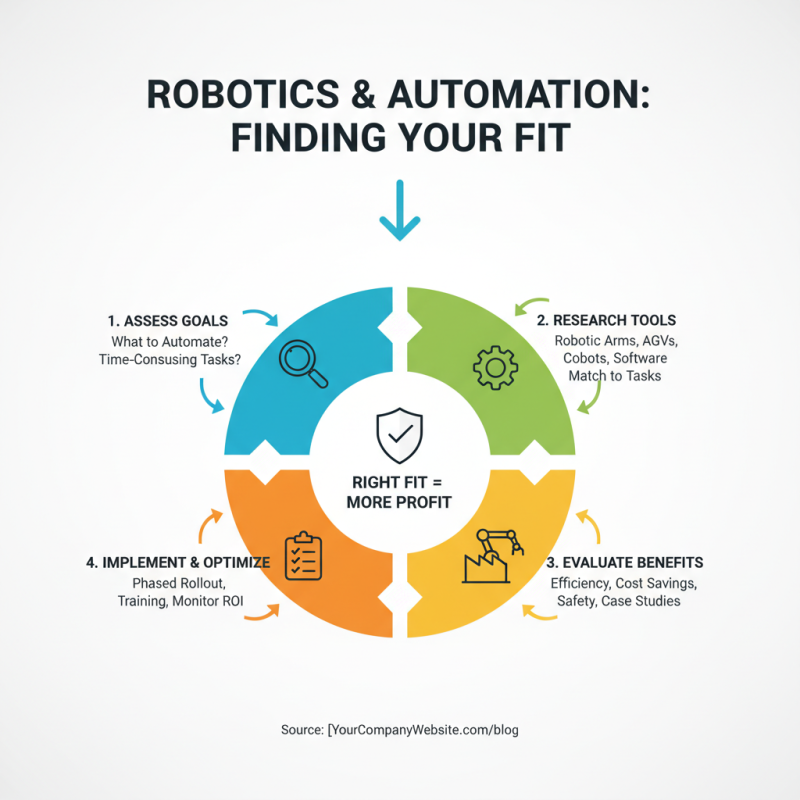

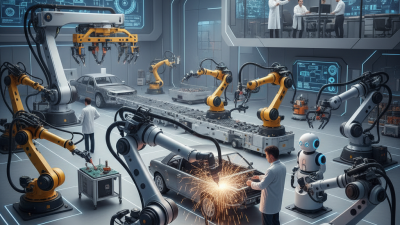

Selecting the right robotics and automation tools for your business needs is essential. Start by assessing your specific goals. What tasks do you want to automate? Consider processes that take up too much time. For instance, robotic arms can handle repetitive tasks in manufacturing. They work tirelessly and can increase efficiency. But are they the right fit for your operation?

Think about integration. New tools should seamlessly connect with existing systems. This often creates challenges. You may need to rethink current workflows. Don’t forget to involve your team in the decision-making process. Their insights can help pinpoint problems that automation may not solve.

Budget constraints are another area to evaluate. High-end solutions can be tempting, but they may not be necessary. Mid-range options could suffice and save costs. It’s also vital to find reliable training resources. The value of automation tools increases significantly when employees know how to use them effectively. Be prepared for some trial and error; not every tool will meet expectations right away.

Strategies for Integration of Robotics into Existing Workflows

Integrating robotics into existing workflows can drive significant business success. According to a McKinsey report, automation can boost productivity by up to 30% in various industries. This figure highlights the potential of technology to enhance efficiency. However, implementation is not always seamless. Many businesses struggle with adapting their current systems, leading to misalignment between new technology and existing processes.

A practical approach involves assessing current workflows. Identify tasks that are repetitive and time-consuming. These are prime candidates for automation. For instance, in logistics, robotic arms can package goods faster than human workers. Yet, many companies fail to consider employee training in their integration strategy. A lack of proper training can hinder the effectiveness of newly implemented robotics.

The enduring challenge lies in balancing automation with human touch. While robots can enhance speed, they cannot replicate human creativity and problem-solving. It is crucial to foster collaboration between humans and machines. A collaborative environment can lead to new insights and adaptations in workflows. Industry experts note that organizations embracing this synergy are more likely to achieve sustainable success.

Measuring the Impact of Robotics on Business Performance and Efficiency

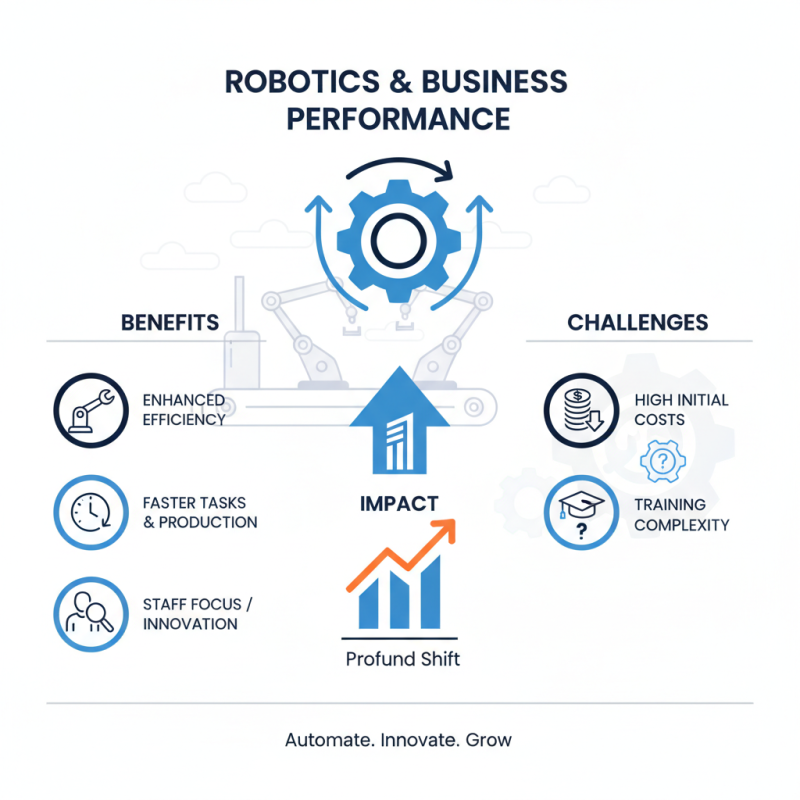

The impact of robotics on business performance is profound. Many companies are turning to automation to enhance efficiency. With robotics, tedious tasks can be performed quickly, freeing up staff for more important work. For example, an automated assembly line can double production speed. However, not all implementations go smoothly. Initial costs can be high, and training staff may take longer than expected.

Measuring the effectiveness of these technologies is crucial. Businesses must track key performance indicators (KPIs) to assess improvement. Metrics such as output rate, error reduction, and labor costs are important. A company may find that while robotics reduce errors, their initial integration creates temporary hiccups in workflow. Continuous monitoring helps identify these challenges and make necessary adjustments.

Feedback from workers is also vital for success. Employees may resist new technology due to fear of job loss or complexity. Engaging them in the transition process can alleviate concerns. Open discussions about robotics can lead to innovative ideas. This collaborative approach often results in a more seamless integration. Ultimately, understanding both the advantages and limitations of robotics is essential for sustained business growth.

Related Posts

-

What is Robotics and Automation and How It Transforms Industries Today

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

How to Implement Robotic Automation in Your Business for Maximum Efficiency

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

10 Best Industrial Robots for Automation in Manufacturing?

-

Top 10 Robotic Automation Solutions You Need to Know?