How to Identify Top Suppliers for the Best Slitting Machine in the Global Market

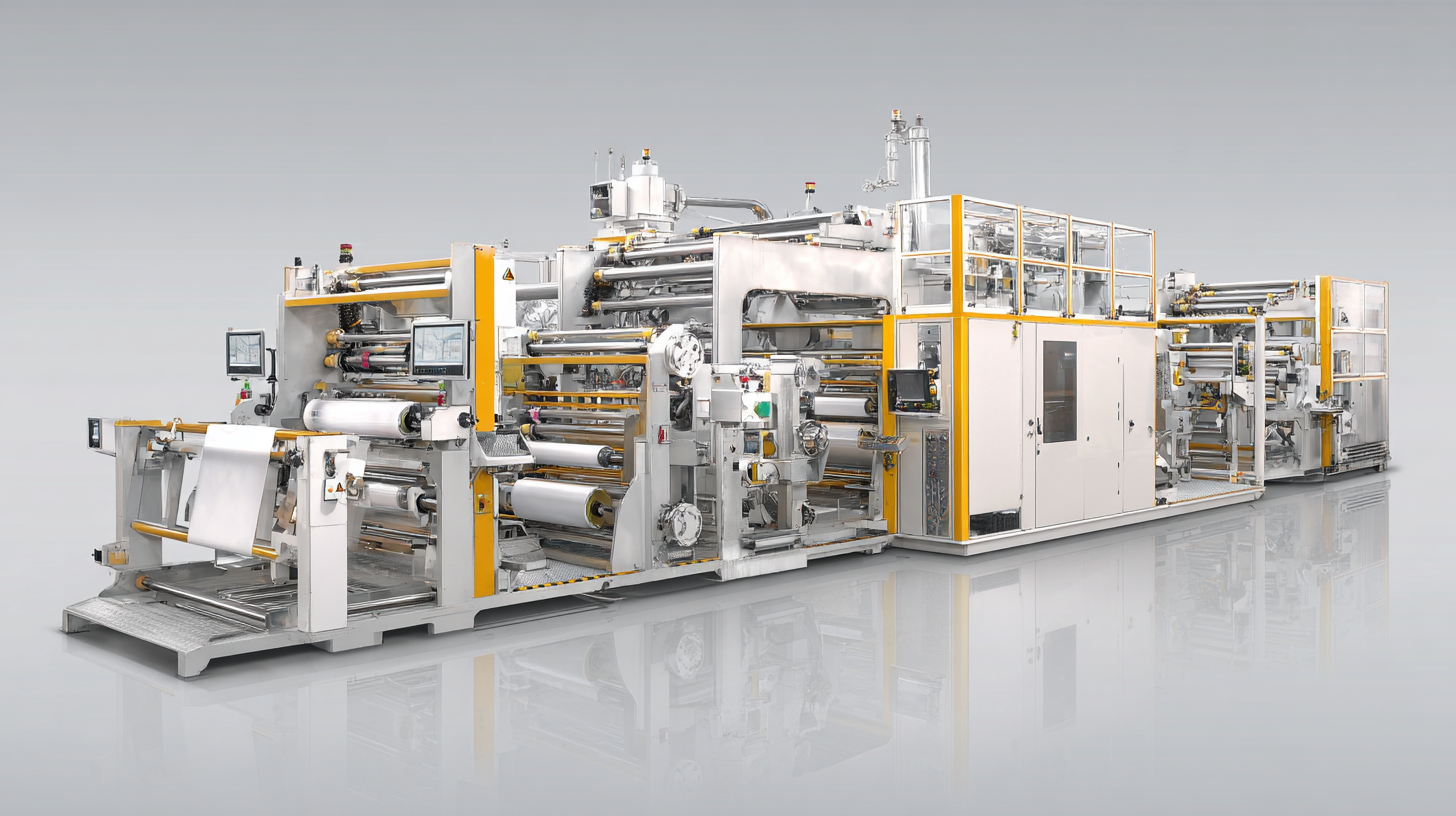

In today's competitive manufacturing landscape, the slitting machine plays a vital role in the efficient processing of a variety of materials, including metals, plastics, and paper. As reported by MarketsandMarkets, the global market for slitting machines is projected to reach USD 2.3 billion by 2025, growing at a CAGR of 4.5%. This significant growth underscores the need for manufacturers to partner with top suppliers who can provide high-quality equipment tailored to their specific needs. However, identifying the right supplier can be challenging due to the diverse range of offerings and specifications available in the market. This ultimate guide will delve into the key factors to consider when seeking out the best slitting machine suppliers, ensuring that manufacturers are well-equipped to make informed decisions that will enhance their operational efficiency and product quality.

Understanding the Importance of Import and Export Certifications in Slitting Machine Selection

In today's global market, selecting the right slitting machine is crucial for manufacturers aiming to enhance productivity and efficiency. A key factor in this selection process is understanding the significance of import and export certifications. These certifications not only ensure compliance with international standards but also demonstrate a supplier's commitment to quality and safety. According to industry reports, machines that meet these certifications often have a higher resale value and reduced regulatory risks, making them a smart investment for businesses.

When evaluating potential suppliers, it's essential to verify their certifications and compliance history. Look for certifications such as ISO and CE, which reflect stringent quality controls and adherence to safety regulations. Additionally, ensure that the supplier has a proven track record of successful international trade, as this can often indicate reliability and expertise in handling various market challenges.

**Tips for Selecting the Right Supplier:**

- Research the supplier’s certification history and their ability to meet your specific needs.

- Attend industry events and public hearings, like the Department of Commerce's discussions on national security concerning imports, to gain insights into market trends and supplier reliability.

- Request detailed documentation of compliance and certifications when considering a supplier. This step will help mitigate risks associated with import restrictions and ensure a smoother operational process.

Key Market Trends Impacting Slitting Machine Suppliers Globally

The global market for slitting machines is experiencing significant shifts influenced by key trends in demand and technology. One of the primary drivers is the increasing need for precision and customization in manufacturing processes. As industries evolve, companies are seeking suppliers that can provide advanced slitting solutions tailored to specific operational requirements. Understanding these trends is crucial when identifying top suppliers in the market.

Another important aspect to consider is the growth rate of the market. The Global Metal Cutting Machine Market is projected to reach USD 10.86 billion by 2033, growing at a CAGR of 6.24%. This growth reflects the rising adoption of automated and efficient cutting solutions, as manufacturers prioritize productivity and quality. Suppliers that are well-versed in these advancements will likely hold a competitive edge.

**Tips for identifying top suppliers include:**

1. Research suppliers' technological capabilities to ensure they can meet modern manufacturing demands.

2. Evaluate their customer service and support, as strong partnerships often lead to better outcomes.

3. Analyze market reports and trends to gain insights into the suppliers’ market positioning and reputation. By focusing on these areas, businesses can better source reliable and innovative slitting machine suppliers.

Evaluating Supplier Credentials: The Role of Industry Standards and Certifications

When searching for top suppliers of slitting machines, one crucial aspect to consider is their credentials, which are significantly influenced by industry standards and certifications. Suppliers with relevant certifications demonstrate their commitment to quality and compliance with established operational standards. For instance, ISO certifications indicate that a supplier adheres to international quality management principles, ensuring consistent product quality and customer satisfaction. Such certifications not only enhance the credibility of suppliers but also assure buyers of their capability to deliver machines that meet stringent performance requirements.

In addition to ISO, suppliers should also be evaluated based on sector-specific certifications that resonate with the slitting machine industry. Engineers and procurement specialists should seek certifications regarding safety standards, environmental impact, and efficiency guidelines. This is critical as it reflects the supplier’s awareness and adherence to contemporary industry trends and regulations. Ultimately, recognizing and valuing these credentials empowers buyers to make informed decisions and fosters long-term partnerships with suppliers who are aligned with best practices and quality assurance in the global marketplace.

Identifying Top Suppliers for Slitting Machines

Analyzing Performance Metrics: What to Look for in High-Quality Slitting Machines

When identifying top suppliers for high-quality slitting machines, it is crucial to analyze performance metrics that directly impact productivity and efficiency. According to the latest projections, the CNC machine market is expected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, demonstrating a significant shift towards advanced manufacturing techniques. This growth underscores the importance of selecting suppliers who not only meet current demands but are also equipped with the latest technological advancements, including machine learning integration for optimized performance.

When evaluating potential suppliers, consider specific performance metrics such as cutting speed, precision, and energy consumption. Suppliers who utilize data-driven approaches and offer predictive maintenance strategies can significantly enhance operational efficiency. For instance, the deployment of machine learning frameworks in optimizing cutting conditions has become a standard. It's beneficial to look for suppliers leveraging such innovations as this can lead to improved machine performance and reduced downtime.

- Examine the supplier's commitment to technological advancements and continuous improvement.

- Investigate their track record in delivering quality machines that align with current production standards.

- Evaluate their support for predictive maintenance solutions that contribute to extended machine lifespan and productivity.

Global Supply Chain Dynamics: How to Mitigate Risks When Choosing Suppliers

In the ever-evolving landscape of global supply chains, mitigating risks when selecting suppliers for slitting machines is paramount for manufacturers. One essential strategy is to conduct thorough research and audits. Assessing the financial stability, production capabilities, and sustainability practices of potential suppliers can provide insights into their reliability and capacity to meet demand fluctuations. Additionally, engaging with multiple suppliers can help diversify risk and create a buffer against unforeseen disruptions, ensuring that production remains uninterrupted.

Another effective approach is to establish strong communication channels. Transparent dialogue with suppliers not only fosters trust but also facilitates quick responses to any issues that may arise. Building these relationships allows for collaboration on problem-solving and innovation, ultimately enhancing the supply chain's resilience. Furthermore, leveraging technology for real-time tracking and data analysis can aid in monitoring supplier performance and anticipating market changes, adding a layer of security to the procurement process. By focusing on these dynamics, suppliers can be chosen strategically, leading to sustainable partnerships that bolster operational efficiency and product quality.