How to Implement Robotic Automation in Your Business for Maximum Efficiency

In today's rapidly evolving business landscape, organizations are increasingly turning to robotic automation as a strategic approach to enhance operational efficiency and productivity. Robotic automation encompasses a range of technologies designed to automate repetitive tasks, allowing businesses to allocate their resources more effectively and focus on innovation and growth. By implementing robotic automation, companies can streamline processes, reduce error rates, and significantly cut down on labor costs, thus gaining a competitive edge in their respective markets.

As the demand for efficiency intensifies, understanding how to effectively integrate robotic automation into your business operations becomes essential. This involves not only selecting the right tools and technologies but also ensuring that your workforce is prepared for the transition. The successful implementation of robotic automation requires careful planning, comprehensive training programs, and ongoing assessment to ensure that the organization reaps maximum benefits. By embracing robotic automation, businesses can position themselves for long-term success while navigating the complexities of modern-market demands.

Understanding Robotic Automation and Its Benefits for Businesses

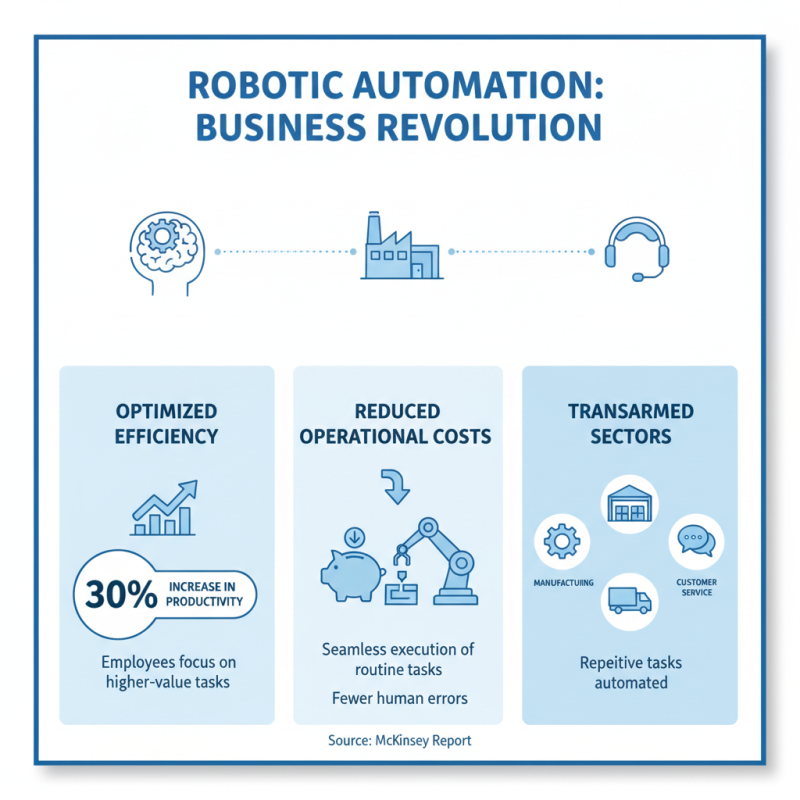

Robotic automation is transforming the landscape of business processes by optimizing efficiency and reducing operational costs. According to a report by McKinsey, companies that have integrated automation into their processes have seen productivity increases by up to 30%. This shift allows employees to focus on higher-value tasks while routine operations are handled by robots or automated systems. The impact is particularly pronounced in sectors such as manufacturing, logistics, and customer service, where repetitive tasks can be seamlessly executed by automation technology.

In addition to enhancing productivity, robotic automation offers significant cost savings. A study from Deloitte indicated that businesses could potentially save around 20-50% on labor costs by implementing automated solutions. Moreover, these technologies can improve accuracy and reduce error rates, leading to higher quality and customer satisfaction. By leveraging data analytics alongside automation, organizations can achieve greater insights into their operations, further informing strategy and decision-making. In an era where efficiency is paramount, understanding and implementing robotic automation is not just an option but a necessity for businesses aiming to thrive.

Assessing Business Processes for Automation Opportunities

To successfully implement robotic automation in your business, it is essential to start with a thorough assessment of your existing processes. Identifying areas where automation could enhance efficiency is crucial. Begin by mapping out your workflows and pinpointing repetitive and time-consuming tasks. Look for processes that involve a high volume of data entry, require extensive decision-making based on fixed criteria, or demand tight deadlines. Opportunities for automation often lie in these repetitive operations, which can lead to significant time and cost savings.

**Tips:** Engage your team in discussions about their daily tasks to gain insights into which processes they find most burdensome. Encourage feedback that can highlight potential automation candidates. Additionally, create a scoring system to rank processes based on the criteria of time consumption, error rates, and overall impact on performance. This will help you prioritize which functions should be automated first.

Once you’ve identified the processes ripe for automation, evaluate the tools available for implementation. Consider factors such as integration capabilities with your existing systems, ease of use, and scalability. A comprehensive understanding of your technology landscape will aid you in selecting the right automation solutions that fit your needs. Engage in pilot testing to validate the effectiveness of automation before a full-scale rollout, ensuring a smoother transition for your team and operations.

**Tips:** Maintain open lines of communication throughout the testing phase. Gather user experiences and address any challenges that arise promptly. This proactive approach will foster a culture of innovation and adaptability within your organization as you move towards greater automation.

Choosing the Right Robotic Automation Tools and Technologies

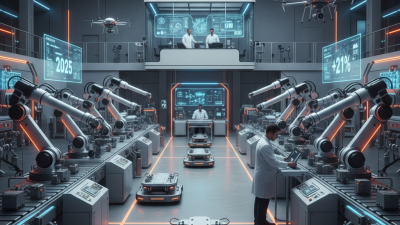

Choosing the right robotic automation tools and technologies is crucial for businesses aiming to enhance operational efficiency. According to a recent report by the International Federation of Robotics, the global market for robotic automation is expected to reach $75 billion by 2025, indicating substantial growth driven by advancements in AI and machine learning. Organizations must assess their specific needs and choose tools that not only integrate seamlessly into their existing workflows but also provide scalability for future growth.

Tip: Conduct a thorough analysis of your business processes to identify areas where robotic automation can deliver the most significant impact. Prioritize tasks that are repetitive, time-consuming, and prone to human error when selecting automation technologies.

Another important factor is understanding the compatibility of various robotic solutions with your current systems. A report from McKinsey suggests that companies effectively adopting automation see productivity increases of up to 30%, emphasizing the role of innovative technologies in achieving substantial efficiency gains. Ensuring that the robotic tools selected can easily interface with your existing infrastructure will streamline the implementation process and optimize results.

Tip: Invest in training your staff on these new technologies to maximize the return on investment. A well-prepared team can leverage the full capabilities of robotic automation, ultimately leading to improved workflow and productivity.

Robotic Automation Tool Adoption by Industry in 2023

This chart illustrates the adoption rates of various robotic automation tools across key industries in 2023. The data highlights the sectors most actively integrating automation technologies to enhance operational efficiency.

Planning and Implementing a Robotic Automation Strategy

Implementing a robotic automation strategy in your business begins with a thorough analysis of your current processes. Start by identifying repetitive tasks that consume a significant amount of time and resources. Engage with your team to gather insights on where inefficiencies lie. This collaborative approach not only uncovers potential areas for automation but also fosters a sense of ownership among employees. Once you have identified these tasks, prioritize them based on their impact on productivity and the ease of implementation.

Next, develop a clear roadmap for the automation process. Set realistic timelines and milestones to keep the project on track. It's crucial to pilot the automation on a smaller scale before a full rollout; this will allow you to evaluate the system's performance and make necessary adjustments. Additionally, provide training sessions for your employees to familiarize them with the new technology. Open communication throughout the implementation process will help alleviate any concerns and ensure that team members are engaged and supportive of the changes. Establishing metrics to evaluate performance post-implementation will further guide improvements and highlight the benefits of the robotic automation you've integrated into your operations.

How to Implement Robotic Automation in Your Business for Maximum Efficiency

| Phase | Key Activities | Expected Outcomes | Timeframe | Resources Required |

|---|---|---|---|---|

| 1. Assessment | Identify processes suitable for automation | List of potential automation candidates | 2 weeks | Internal team, process documentation |

| 2. Strategy Development | Define objectives and KPIs | Clear roadmap for automation benefits | 3 weeks | Stakeholder engagement, meetings |

| 3. Technology Selection | Evaluate and choose automation tools | Selected technology stack | 4 weeks | Evaluation criteria, vendor demos |

| 4. Implementation | Develop and test automation workflows | Working automated processes | 6 weeks | Development team, testing resources |

| 5. Monitoring & Optimization | Track performance and refine processes | Improved efficiency and productivity | Ongoing | Monitoring tools, feedback sessions |

Monitoring and Optimizing Automated Processes for Continuous Improvement

Monitoring and optimizing automated processes is crucial for businesses aiming to achieve continuous improvement. Once robotic automation is implemented, the focus should shift to tracking performance metrics and identifying areas that require enhancement. Utilizing data analytics tools can provide insightful feedback on process efficiency, error rates, and resource utilization. Regularly reviewing these metrics allows organizations to pinpoint bottlenecks or inefficiencies, leading to informed decisions about necessary adjustments.

In addition to performance monitoring, establishing a feedback loop is essential for sustained optimization. Encouraging employee input—particularly from those directly interacting with automated systems—can uncover insights that data alone might miss. This collaborative approach fosters an environment where automation evolves in alignment with business needs. Furthermore, iterative testing of new processes or algorithm modifications ensures that improvements are continuously adapted, ultimately reinforcing the automation framework for maximum efficiency. Emphasizing ongoing training and support for staff interacting with automated systems enhances their ability to identify issues promptly, facilitating quicker resolutions and a more agile response to market changes.

Related Posts

-

What is Robotics and Automation and How It Transforms Industries Today

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

Top 5 Reasons Why Fanuc Robots Lead the Automation Industry with 20 Percent Market Share

-

Understanding the Essence of Robotics: What Defines a Robot in Today’s Tech Landscape

-

10 Best Robot Machines for Efficient Automation in 2023