How to Implement Robotic Automation Solutions for Your Business

In today's fast-paced business environment, companies are constantly seeking ways to enhance efficiency. One solution that has gained immense popularity is implementing robotic automation solutions. These technologies streamline repetitive tasks, allowing employees to focus on more complex issues. However, the adoption of such systems is not without challenges.

Integrating robotic automation requires careful planning and consideration. Businesses must evaluate their existing processes to identify areas for automation. It's crucial to understand that not every task is suitable for robots. Limited understanding of these technologies can lead to expensive mistakes. Companies need to invest in the right training and resources for their teams.

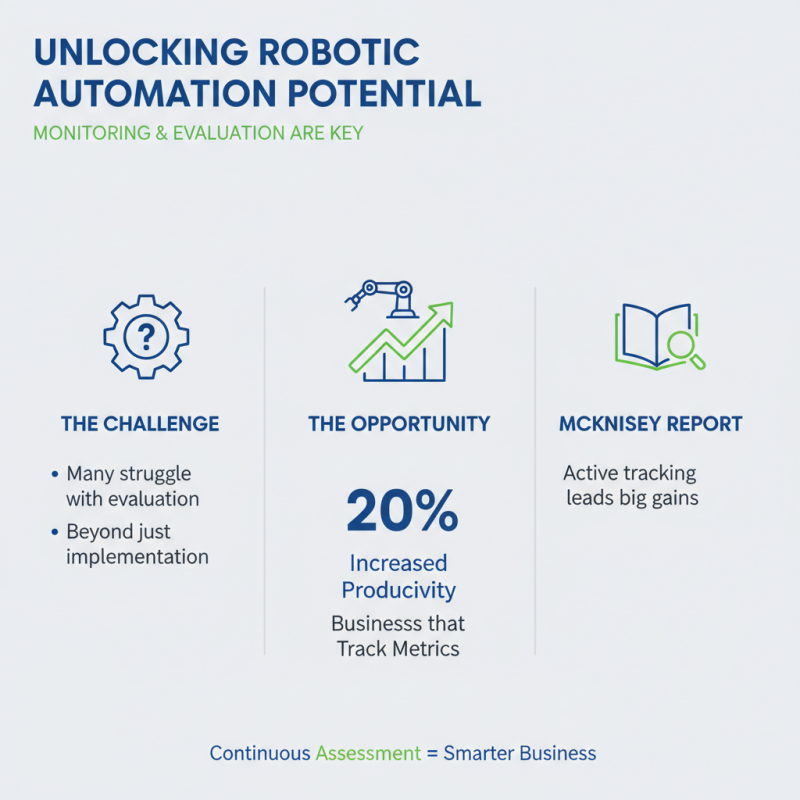

Additionally, there's a need for continuous assessment. Once robotic systems are in place, monitoring their performance is essential. Metrics must be established to gauge effectiveness and discover areas for improvement. Embracing robotic automation solutions is a journey, not just a destination. Organizations must remain adaptable and willing to evolve as technologies advance.

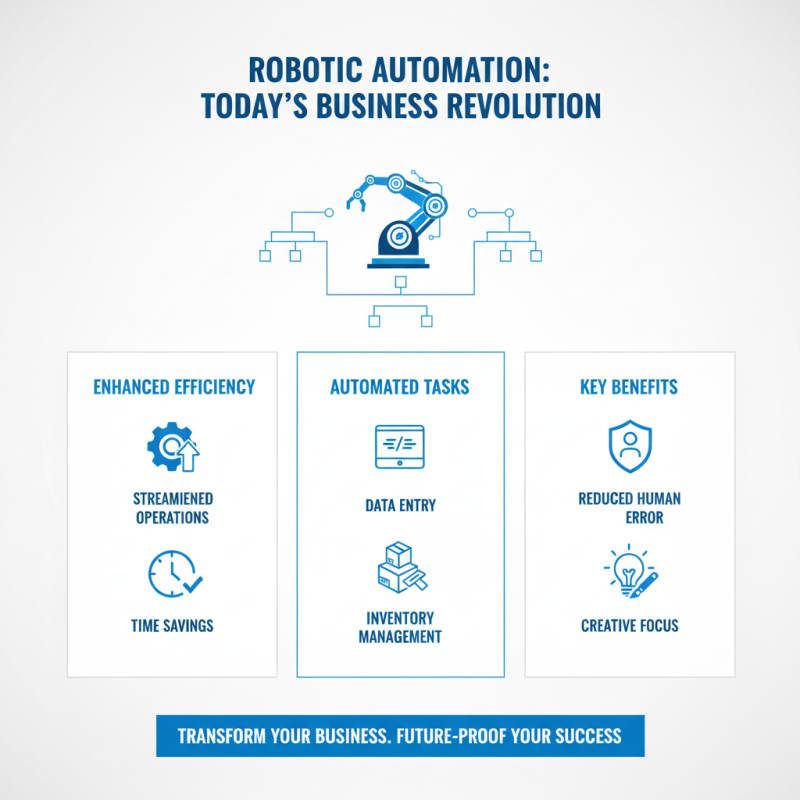

Understanding Robotic Automation and Its Benefits for Businesses

Robotic automation, often seen as a futuristic concept, is already transforming many businesses today. By incorporating robotic solutions, companies can enhance efficiency significantly. Routine tasks, such as data entry or inventory management, can be automated. This reduces human error and saves time, allowing employees to focus on more creative aspects of their work.

One must consider the initial investment in robotics. While the long-term savings are impressive, the upfront cost can be daunting. Some businesses may struggle during the transition phase. Employees might feel threatened by automation. It’s crucial to address these concerns early. Training programs can help staff adapt and embrace new tools. Involving everyone in the process fosters a smoother implementation.

The benefits of robotic automation are clear. Increased productivity is often the most noticeable change. However, companies should also watch for potential pitfalls during implementation. Communication is key. Regular feedback will help identify issues before they escalate. This reflection can lead to a more sustainable and effective use of robotic solutions in the workplace.

Identifying the Right Processes for Automation in Your Organization

Identifying the right processes for automation is crucial. Start by analyzing repetitive tasks in your organization. Look closely at areas like data entry, invoicing, or customer inquiries. These tasks often consume time and resources. Automation can streamline these processes and reduce human error.

Consider the impact on employee roles. Some may feel threatened by automation. Address these concerns openly. Ensure employees understand that automation can improve their productivity. It allows them to focus on more strategic tasks. It’s essential to foster a culture of collaboration between man and machine.

Evaluate the necessary technology. Not all tools fit every process. Take time to assess what works best for your specific needs. Implementation can be challenging. You may encounter resistance or technical glitches. Reflect on these obstacles as learning opportunities. Transformation requires continuous improvement and adaptation.

Choosing the Appropriate Robotic Automation Tools and Technologies

Choosing the right robotic automation tools is crucial for any business looking to elevate its efficiency. Start by identifying your specific needs. Are you aiming to streamline logistics, enhance customer service, or improve manufacturing processes? Each area requires different solutions. Understanding the unique challenges in your operations will guide you in selecting the most fitting technology.

Consider the scale of your operations. A small business may require lightweight, user-friendly tools. In contrast, larger enterprises might benefit from more complex systems. It's vital to evaluate the integration capacity of these tools. Can they adapt to existing processes? Test a few solutions before fully committing. Learning from any missteps will help refine your choice.

Keep an eye on emerging technologies too. The landscape evolves rapidly, and solutions that seem ideal today may not hold the same value in a few years. Be prepared to reassess and adapt your tools. Automation should ultimately serve your business goals, not the other way around.

Implementing and Integrating Automation Solutions into Existing Workflows

Integrating automation solutions into existing workflows can be challenging. Many businesses struggle to identify the right processes for automation. Often, employees resist change. They feel unsure about their roles once automation is introduced. This can create tension and a lack of collaboration.

To overcome these challenges, start with a thorough analysis of current workflows. Identify repetitive tasks that consume time but do not require human decision-making. For instance, data entry or report generation can often be automated. Involve your team in discussions. Gather feedback on which tasks they find mundane or time-consuming. These insights can reveal areas where automation could be beneficial.

Once you pinpoint suitable tasks, choose user-friendly automation tools. Ensure they can seamlessly integrate with your existing systems. Training is essential. Employees must feel confident using new tools. Consider creating a trial period for a limited scope. Monitor performance and adjust as needed. This iterative approach can alleviate initial concerns and gradually build acceptance within the team. Reflect on the process continuously to ensure long-term success.

How to Implement Robotic Automation Solutions for Your Business

| Aspect | Description | Benefits | Estimated Cost | Implementation Timeframe |

|---|---|---|---|---|

| Process Identification | Identify repetitive tasks suitable for automation. | Increased efficiency and reduced human error. | $1,000 - $5,000 | 2 - 4 weeks |

| Tool Selection | Choose the appropriate automation tools and software. | Cost savings and improved productivity. | $5,000 - $20,000 | 1 - 2 months |

| Integration | Integrate the automation tools into existing workflows. | Seamless operation and enhanced data flow. | $10,000 - $50,000 | 3 - 6 months |

| Training | Train staff to use new automation processes. | Maximized usage and reduced frustration. | $2,000 - $8,000 | 1 - 2 months |

| Monitoring | Monitor automation performance and troubleshoot issues. | Continuous improvement and optimization. | $3,000 - $10,000/year | Ongoing |

Monitoring and Evaluating the Performance of Automated Systems

Monitoring and evaluating the performance of automated systems is crucial for any business implementing robotic automation solutions. According to a recent report by McKinsey, businesses that actively track automation metrics improve productivity by up to 20%. However, despite these numbers, many companies struggle to establish effective evaluation techniques. It’s not just about implementation; ongoing assessments are essential.

Establishing key performance indicators (KPIs) is one of the best practices. Focus on metrics like cycle time, error rates, and throughput. Regularly compare these metrics against targets. Surveys show that 60% of companies fail to revisit their KPIs post-implementation. This oversight can lead to performance stagnation.

Tip: Invest in analytics tools that provide real-time data. This allows immediate adjustments and insight into operational bottlenecks. Don't rely solely on historical data. Immediate feedback fosters a responsive environment, but you must remain vigilant. Be open to iterating your processes as new challenges emerge. Each robotic implementation might reveal unforeseen issues; embrace these as opportunities for growth.

Related Posts

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

10 Surprising Ways Automation Machines are Transforming Small Businesses in 2023

-

Understanding the Essence of Robotics: What Defines a Robot in Today’s Tech Landscape

-

Revolutionizing Efficiency: How the Automation Industry is Expected to Surge by 30% by 2025

-

What is Robotics and Automation and How It Transforms Industries Today

-

10 Best Robot Machines for Efficient Automation in 2023