Innovative Technologies Shaping the Future of Best Stretch Film Blowing Machines in 2025

As we look towards 2025, the landscape of packaging technology is rapidly evolving, with innovative advancements driving the industry forward. Among these developments, the Stretch Film Blowing Machine stands out as a pivotal player in enhancing efficiency and sustainability in packaging solutions. This blog will explore the various types of stretch film blowing machines available in the market, highlighting their unique features, capabilities, and how they compare against each other. By analyzing cutting-edge technologies such as automation, energy efficiency, and material optimization, we aim to provide readers with a comprehensive understanding of how these machines are shaping the future of manufacturing and distribution. Join us on this journey as we delve into the transformative impact of these machines in creating a more efficient and environmentally-friendly packaging process.

The Role of Advanced Materials in Enhancing Stretch Film Performance by 2025

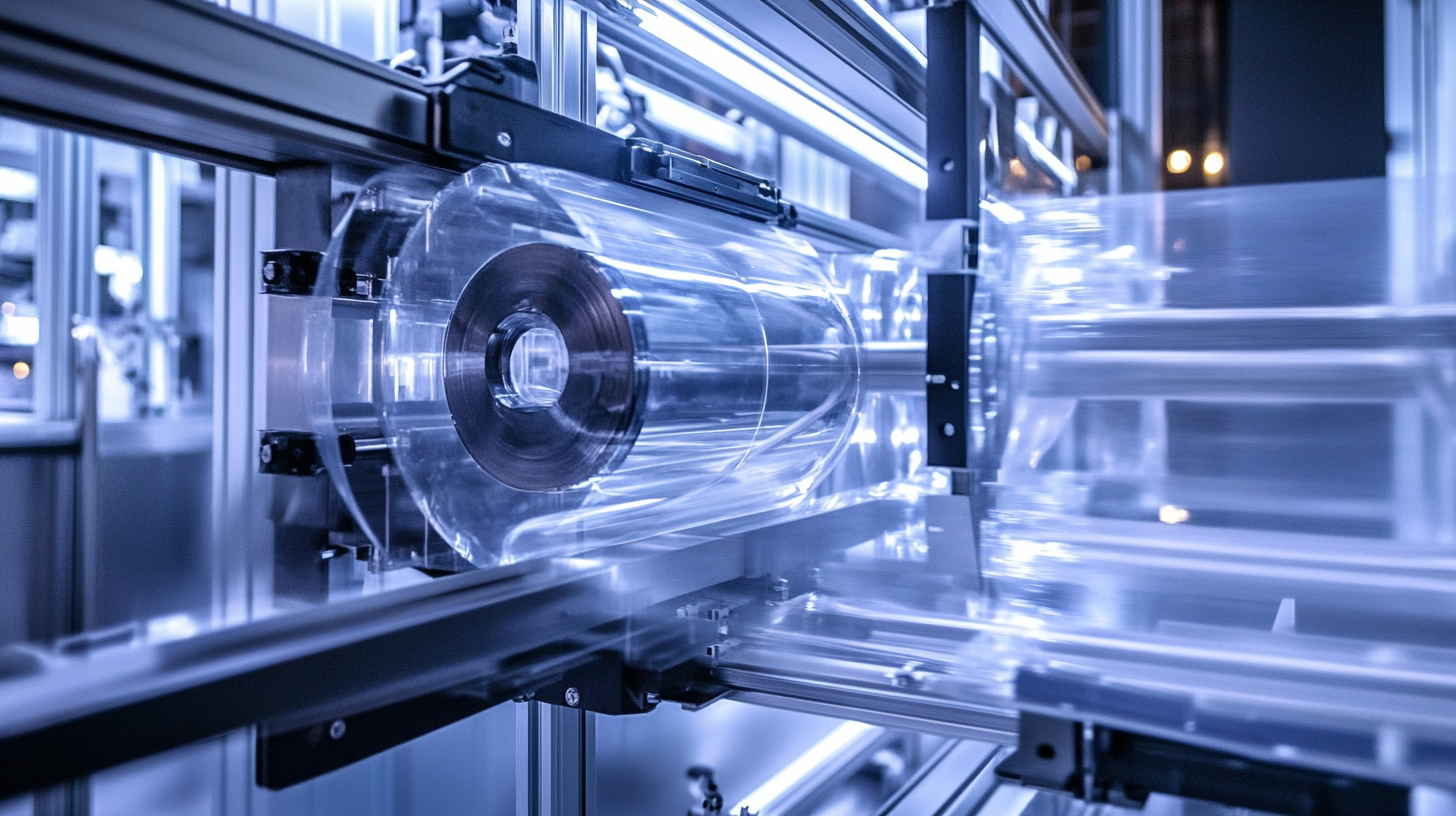

In the quest for superior stretch film performance by 2025, the integration of advanced materials is set to revolutionize the blowing machine industry. According to a report by Smithers Pira, the global market for stretch film is projected to reach $12.7 billion by 2025, driven by a growing demand for sustainable packaging solutions. Innovations in resin technology, such as the use of bio-based materials and enhanced polyolefins, are expected to enhance film strength and flexibility while reducing environmental impact.

One key trend is the development of multi-layer films that utilize advanced barrier properties. These films not only improve the shelf life of products but also minimize waste, aligning with sustainability goals emphasized in recent industry publications. Additionally, the incorporation of nanomaterials can significantly bolster film performance, offering greater puncture resistance and transparency.

Tips for manufacturers looking to leverage these advancements include investing in R&D for material innovations and exploring partnerships with suppliers who prioritize sustainable practices. Understanding the specific properties of materials and their impact on production efficiency can help streamline processes and enhance product offerings, ensuring that companies remain competitive in an evolving market landscape.

Innovative Technologies Shaping the Future of Best Stretch Film Blowing Machines in 2025

| Technology | Description | Benefits | Year of Introduction |

|---|---|---|---|

| Biodegradable Materials | Use of eco-friendly, compostable materials for stretch films. | Reduced environmental impact and compliance with regulations. | 2023 |

| Smart Sensors | Integration of sensors for real-time monitoring of film thickness and tension. | Improved consistency and quality of stretch film production. | 2024 |

| Recyclable Materials | Development of stretch films that can be easily recycled. | Promotion of a circular economy and waste reduction. | 2022 |

| Enhanced Polyethylene | Research into new formulations of polyethylene for increased strength and elasticity. | Better load retention and stretching capabilities. | 2025 |

| Energy-Efficient Production | Adoption of energy-efficient technologies in the blowing process. | Lower energy costs and reduced carbon footprint. | 2023 |

Exploring Industry Standards and Certifications for Stretch Film Blowing Machines

The stretch film blowing machines are evolving rapidly, driven by innovative technologies and a focus on industry standards and certifications. As the market for stretch wrapping continues to expand, manufacturers are increasingly scrutinizing the efficiency and sustainability of their machinery. In 2025, one can expect to see significant advancements in machine design and operational protocols that comply with global industry standards. The integration of smart technologies, such as IoT-enabled devices and automation, will likely become a norm, enhancing the overall production capabilities and reducing waste.

Additionally, adherence to stringent certifications will play a crucial role in shaping the industry landscape. Certifications focused on environmental impact and material safety are becoming imperative for manufacturers aiming to establish credibility and trust in the market. The distinction between types, specifically Cast Wrap and Blown Wrap, will also necessitate precise adherence to material specifications like polyethylene (PE) and low-density polyethylene (LDPE). These shifts not only reflect a commitment to quality but also an evolving understanding of consumer demand for sustainable and responsible manufacturing practices.

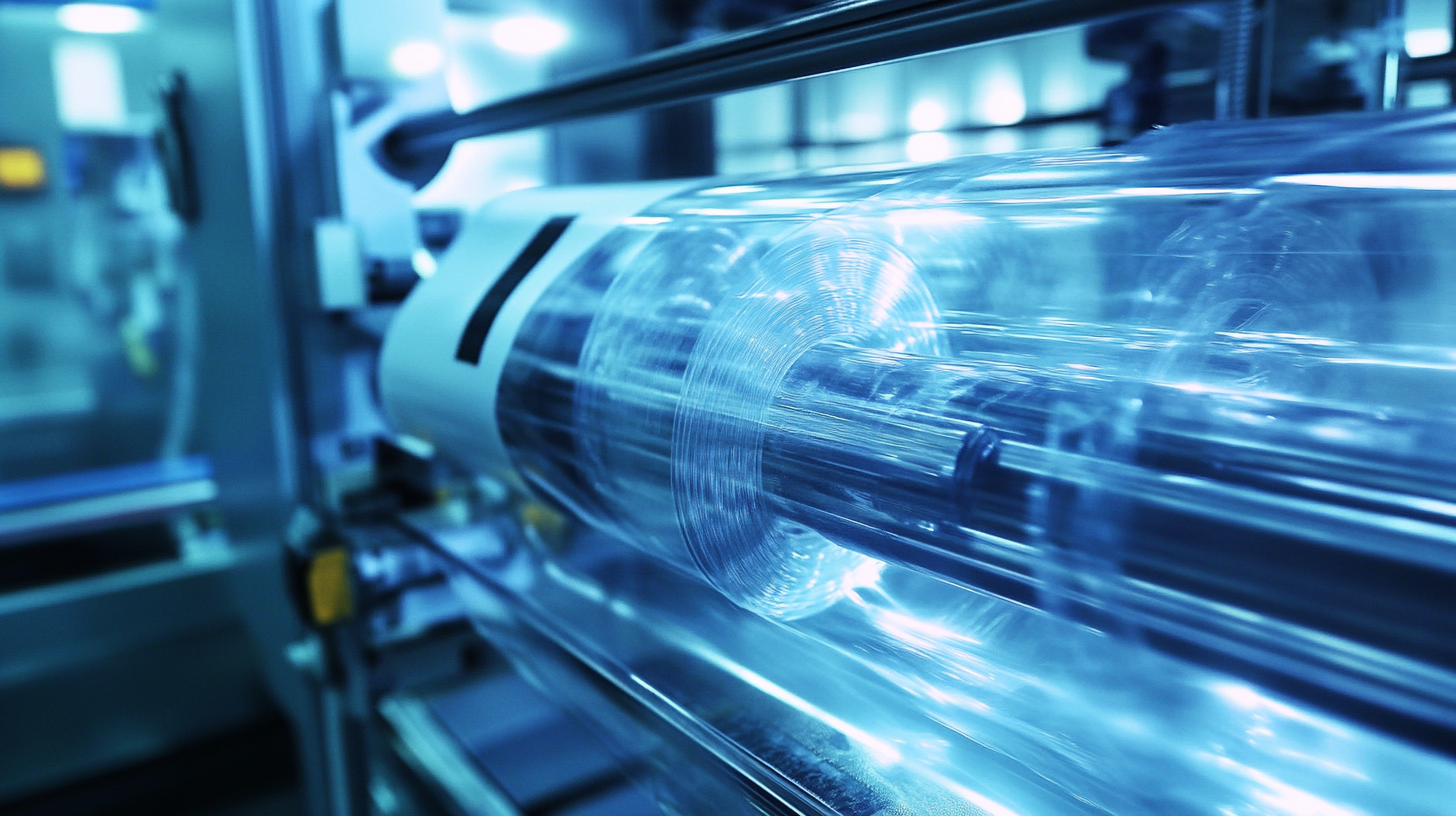

Emerging Automation Technologies Transforming Stretch Film Production Processes

The landscape of stretch film production is undergoing a remarkable transformation in 2025, fueled by emerging automation technologies that enhance efficiency and precision. As manufacturers seek to optimize their production processes, the integration of advanced robotics, artificial intelligence, and machine learning is becoming increasingly prevalent. These technologies enable machines to perform complex tasks with greater accuracy, minimizing waste and reducing the risk of human error during the blowing process. Automation not only streamlines operations but also allows for real-time monitoring and adjustments, ensuring consistent quality in the final product.

Moreover, the incorporation of smart sensors and IoT connectivity plays a crucial role in this evolution. By linking stretch film blowing machines to cloud-based systems, manufacturers can gather valuable data on machine performance, throughput, and raw material usage. This data-driven approach empowers companies to make informed decisions about maintenance, energy consumption, and overall productivity. As these innovations continue to shape the production landscape, manufacturers will be better equipped to meet the increasing demands of the market while maintaining sustainability and cost-effectiveness in their operations.

Innovative Technologies Shaping the Future of Stretch Film Production

Sustainable Practices in Stretch Film Manufacturing: Trends and Innovations

As the demand for stretch films continues to rise, manufacturers are increasingly adopting sustainable practices to minimize environmental impact. Innovations in material science have led to the development of biodegradable and recyclable stretch films, allowing companies to meet customer demands for eco-friendly options without sacrificing performance. These films make use of advanced polymers that break down more easily in landfills, significantly reducing the long-term environmental footprint associated with traditional plastic films.

Moreover, energy-efficient technologies are becoming integral to the manufacturing process of stretch films. Advanced blowing machines are now being designed to consume less energy while maintaining higher production rates. These machines utilize smart technology to optimize operational efficiency, resulting in lower waste and reduced energy consumption. By implementing these sustainable practices, stretch film producers not only comply with regulatory requirements but also appeal to environmentally-conscious consumers, fostering a new era of responsible manufacturing in the industry.

Market Analysis: Demand Forecast for Stretch Film Blowing Machines Until 2025

The global stretch film market is poised for substantial growth, with projections indicating a rise from $4.68 billion in 2025 to $6.71 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.27%. This upward trajectory underscores the increasing demand for efficient packaging solutions, driven by the expanding e-commerce sector and the need for sustainable packaging practices. As companies continue to prioritize cost-effectiveness and product protection, innovative technologies in stretch film blowing machines will undoubtedly play a crucial role in meeting these demands.

Tip: For businesses interested in entering or expanding within the stretch film market, staying abreast of technological advancements is essential. Investing in the latest blowing machine technologies can enhance production efficiency and product quality, enabling manufacturers to keep pace with market growth.

Additionally, the cling film market is also on the rise, as it is projected to witness significant advancements alongside the stretch film sector. By focusing on flexibility and innovative manufacturing processes, companies can capitalize on this growing demand. The pallet wraps market is similarly forecasted to grow robustly, anticipated to reach a noteworthy USD 6.8 billion, reinforcing the overall trend towards improved packaging solutions across various industries.

Tip: Leverage market analysis data to inform strategic decisions and product development. Understanding these trends will help businesses not only to optimize their offerings but also to align with consumer preferences and regulatory standards in sustainability and efficiency.