How to Integrate Robotics and Automation for Enhanced Business Efficiency

In recent years, the incorporation of robotics and automation into business operations has emerged as a pivotal strategy for enhancing efficiency and productivity. According to a report by McKinsey, automation could raise global productivity by up to 1.4% annually, resulting in substantial economic growth. The International Federation of Robotics (IFR) also highlights that investments in robotics have been soaring, with a projected increase of 21% in global robot sales by 2025. This trend underscores the imperative for businesses to integrate these technologies not just as a means of reducing labor costs, but as a fundamental shift towards smarter and more agile operations.

Strategies for Assessing Business Needs for Robotics Integration

Assessing business needs for robotics integration is crucial to maximizing efficiency and productivity. According to a report by Deloitte, nearly 70% of companies are either actively integrating or planning to integrate robotic process automation (RPA) into their operations. This shift represents a significant opportunity for businesses to streamline repetitive tasks, thus allowing employees to focus on more strategic initiatives. To start, businesses should conduct a thorough analysis of their workflows, identify pain points, and evaluate which processes are ripe for automation.

Furthermore, a survey by McKinsey highlights that organizations that successfully implement robotics can expect productivity gains of 20-40%. This statistic underscores the importance of understanding specific organizational goals before embarking on robotic integration. By engaging with stakeholders across different departments, businesses can gather valuable insights that inform a tailored automation strategy.

In doing so, they can create a roadmap that not only enhances operational efficiency but also aligns technology investments with overarching business objectives. Emphasizing clear communication and collaboration in this assessment phase will ultimately increase the chances of successful integration.

Key Technologies Driving Automation in Business Operations

As businesses increasingly adopt technologies to enhance operational efficiency, Robotics Process Automation (RPA) has emerged as a pivotal player in streamlining processes. By leveraging software and services, RPA automates rule-based tasks, freeing up human resources for more strategic endeavors. This transition is particularly vital as organizations navigate complex environments, requiring faster decision-making and increased agility. The insights gained from RPA implementation highlight the importance of adaptive technologies that can evolve with business needs.

Furthermore, the integration of advanced AI agents is reshaping industries like banking, where intelligent automation is revolutionizing service delivery. To fully realize the potential of these technologies, businesses must reevaluate their existing workflows and embrace innovative approaches. The collaborative efforts between tech firms and cloud service providers showcase the potential for creating comprehensive solutions that drive automation across various sectors. This alignment of technology and industry experience is central to achieving higher operational standards and fostering a culture of continuous improvement.

Best Practices for Implementing Robotics and Automation Solutions

The integration of robotics and automation is becoming increasingly essential for businesses aiming to enhance efficiency and agility in a rapidly evolving market landscape. The Robotic Process Automation (RPA) market is poised to grow significantly, with a projected value of $4.29 billion in 2023 and an impressive compound annual growth rate (CAGR) of 21.46% expected through 2031. This growth underscores the vital role RPA plays in driving operational efficiencies, as organizations adopt these technologies to streamline processes and reduce manual intervention.

Best practices for implementing robotics and automation solutions include leveraging AI-driven processes that not only automate routine tasks but also adapt to complex business needs. As noted in recent industry reports, by the end of 2022, the fusion of AI-driven automation across various business lines was estimated to generate nearly $3 trillion globally. Businesses are urged to explore innovative use cases, particularly the integration of AI with RPA, to unlock new levels of efficiency.

The collaboration between industry leaders exemplifies the shifting focus toward integrated automation solutions that promise to redefine operational capabilities and customer interactions in the years to come.

Measuring the Impact of Robotics on Operational Efficiency

The integration of robotics and automation in business processes has gained significant attention due to its potential to enhance operational efficiency. Measuring the impact of robotics involves analyzing various metrics, including production speed, accuracy, and labor costs. By replacing manual tasks with robotic systems, businesses can significantly reduce human error and streamline workflows, resulting in faster turnaround times and higher output quality.

Furthermore, it is essential to consider the long-term benefits of robotics on workforce dynamics. Automation can free up employees from repetitive tasks, enabling them to focus on higher-value activities that require critical thinking and creativity. By tracking key performance indicators (KPIs) such as employee satisfaction and overall productivity levels, organizations can gauge the positive effects of robotic integration on their overall efficiency. As businesses continue to embrace these technological advancements, understanding their measurable impact becomes crucial for strategic decision-making and sustained growth.

How to Integrate Robotics and Automation for Enhanced Business Efficiency - Measuring the Impact of Robotics on Operational Efficiency

| Key Metric | Before Automation | After Automation | Percentage Improvement |

|---|---|---|---|

| Production Time (hours) | 200 | 120 | 40% |

| Labor Costs ($) | $50,000 | $30,000 | 40% |

| Error Rate (%) | 5% | 1% | 80% |

| Inventory Turnover Ratio | 3 | 5 | 66.67% |

| Customer Satisfaction Rate (%) | 75% | 90% | 20% |

Future Trends in Robotics and Automation for Business Growth

The future of robotics and automation is poised to revolutionize business operations, driving efficiency and growth across various sectors. As technology advances, we are witnessing an emergence of smart robots equipped with artificial intelligence, enabling them to learn and adapt to new tasks autonomously. This capability not only enhances productivity but also minimizes human error, providing businesses with a competitive edge. For instance, industries such as manufacturing and logistics are increasingly relying on robotic process automation (RPA) to streamline workflows, reduce costs, and accelerate delivery times.

Moreover, the integration of robotics with IoT (Internet of Things) is creating opportunities for real-time data analysis, further enhancing decision-making processes. Businesses can leverage this data to optimize supply chains, predict maintenance needs, and improve customer service. Collaborative robots, or cobots, are also on the rise, allowing human workers and machines to work side by side safely. As these technologies evolve, organizations that strategically invest in robotics and automation will not only enhance their operational efficiency but also position themselves for sustained growth in a rapidly changing market landscape.

Impact of Robotics and Automation on Business Efficiency (2023)

This bar chart illustrates the percentage efficiency gains achieved through the integration of robotics and automation across various business areas in 2023. Manufacturing and warehouse operations lead the way, demonstrating significant improvements in productivity and operational efficiency.

Related Posts

-

What is Robotics and Automation and How It Transforms Industries Today

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

Top 5 Reasons Why Fanuc Robots Lead the Automation Industry with 20 Percent Market Share

-

Understanding the Essence of Robotics: What Defines a Robot in Today’s Tech Landscape

-

10 Best Robot Machines for Efficient Automation in 2023

-

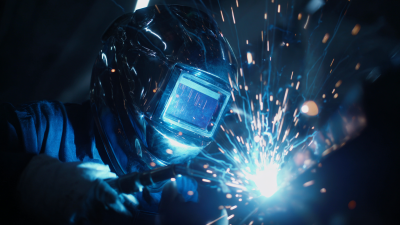

Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency