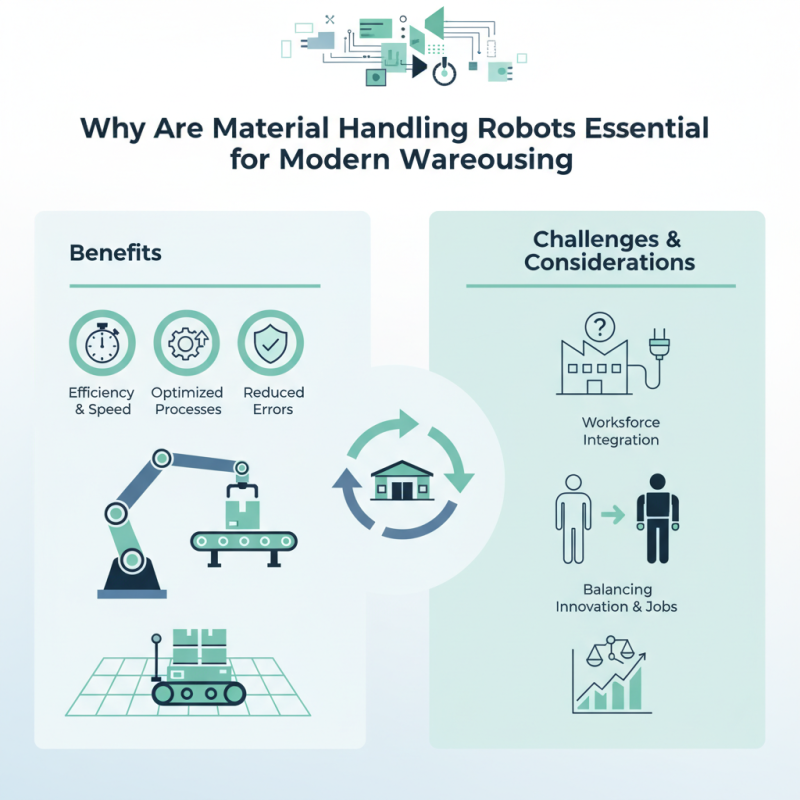

Why Are Material Handling Robots Essential for Modern Warehousing

In the rapidly evolving world of logistics, material handling robots have become indispensable. Experts in the field, like Dr. Susan Carl, emphasize their impact: "Material handling robots transform efficiency in warehouses." These machines streamline processes that were once manual and slow.

Today, warehouses face pressure to perform better. Increased demand for fast delivery puts a spotlight on efficiency. Material handling robots can automate repetitive tasks, such as sorting and transporting goods. They work tirelessly, reducing human error. This leads to faster processing times and fewer delays.

Yet, challenges persist. Some companies struggle with implementation. Not all warehouses are equipped or ready for such technology. Workers may feel threatened by automation. Balancing innovation with human jobs remains a concern. However, the benefits of material handling robots often outweigh these drawbacks. As the industry evolves, their role is sure to grow.

The Growing Importance of Automation in Warehousing

Automation has revolutionized the way warehouses operate. Material handling robots play a critical role in this shift. These machines amass, sort, and transport goods more efficiently than human workers. They reduce the time taken to complete tasks and minimize errors during handling. This efficiency is vital in meeting consumer demand.

Despite these advantages, automation comes with challenges. Initial setup costs can be high. Some employees may feel threatened by the technology. There’s also a learning curve involved in training staff to work alongside robots. Issues such as maintenance and system updates can interrupt workflow. It’s crucial for companies to address these hurdles to fully embrace automation.

As warehousing grows increasingly complex, the need for advanced systems is clear. Robots can operate continuously, lifting heavy loads without fatigue. They adapt to fluctuating inventory levels, ensuring efficient stock management. This adaptability is key to thriving in a competitive market. However, businesses must remain vigilant about the potential drawbacks while leveraging these tools to enhance productivity.

Key Benefits of Material Handling Robots in Supply Chain Efficiency

In today's fast-paced supply chain landscape, material handling robots emerge as crucial players. They facilitate efficiency in warehouses by automating repetitive tasks. This reduces the time employees spend on mundane activities, allowing them to focus on value-added processes. Robots transport goods swiftly and accurately, minimizing human error. They can work tirelessly, moving pallets or stacking boxes without fatigue.

The benefits extend beyond simple labor savings. Robots enhance inventory management, improving accuracy and tracking. They provide real-time data, which helps in forecast planning. This data can be insights into stock levels, ensuring products are always available. However, reliance on these robots can pose challenges. Technical malfunctions can disrupt operations. If not monitored, this could lead to delays and misplaced items.

Moreover, not every task suits robotic automation. Some complex decision-making still requires human intervention. Companies must find the right balance between machines and skilled workers. As we embrace these innovations, it is essential to reflect on their limitations too. Adopting technology without considering its drawbacks may lead to operational pitfalls.

Types of Material Handling Robots Used in Modern Warehouses

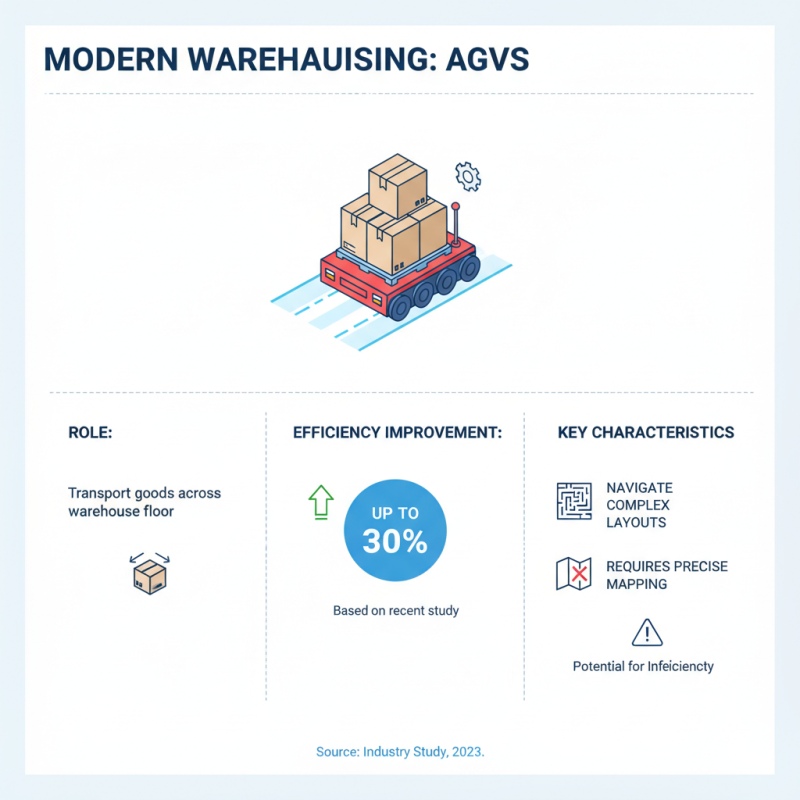

In modern warehousing, several types of material handling robots play crucial roles. Automated guided vehicles (AGVs) are common. They transport goods across the warehouse floor. According to a recent study, AGVs can improve efficiency by up to 30%. Their ability to navigate complex layouts is impressive, yet they require precise mapping. Mistakes in layout can lead to inefficiencies.

Another type is robotic arms. These robots automate processes like picking and packing. They can handle a variety of products, from boxes to fragile items. A report indicated that integrating robotic arms can reduce labor costs by 20-25%. However, the initial setup is costly and requires training. Ensuring smooth operations can be challenging.

Mobile robots are also gaining traction. Designed for specific tasks, they enhance productivity and flexibility. Data show that mobile robots can improve order fulfillment speed by 40%. Still, their dependency on stable Wi-Fi signals can pose problems. If connectivity issues arise, operations may slow down. Different robots serve different needs, yet challenges remain for implementation and adaptation in diverse environments.

Impact of Robotics on Labor and Workforce Dynamics in Warehousing

The integration of robotics in warehousing has transformed labor dynamics significantly. Robots take on repetitive tasks. This change frees human workers to focus on more complex activities. It’s not just about efficiency; it’s about enhancing job roles. Workers can now engage in planning or quality control. This shift can elevate job satisfaction.

However, the shift toward automation also raises concerns. Some workers fear job loss as robots become more capable. The reality is mixed. While certain jobs may disappear, new roles emerge. Employees may need to adapt swiftly. Training programs are crucial to bridge this gap. Companies must invest in upskilling their workforce. A continuous learning environment is necessary.

Workforce dynamics are evolving. Collaboration between humans and robots is vital. The challenge lies in maintaining balance. Empathy and human intuition cannot be replicated easily. Yet, harnessing these traits alongside robotic efficiency could lead to a more effective workplace. Embracing change is essential, but not without reflection on its impacts.

Why Are Material Handling Robots Essential for Modern Warehousing - Impact of Robotics on Labor and Workforce Dynamics in Warehousing

| Dimension | Description | Impact on Workforce | Statistics |

|---|---|---|---|

| Efficiency | Improves speed of order fulfillment | Reduces labor hours needed | 30% increase in order processing speed |

| Safety | Minimizes human exposure to hazardous tasks | Lower workplace accidents | 50% reduction in injury rates |

| Cost Savings | Reduces operational costs over time | Shifts roles from manual tasks to oversight | 20-30% reduction in labor costs |

| Flexibility | Can be adapted to various tasks | Allows for job diversification | 70% of respondents feel more engaged |

| Data Collection | Automated data on inventory and performance | Enhances decision-making processes | Improved accuracy in inventory up to 99% |

Future Trends in Material Handling Robotics for Warehousing Solutions

The landscape of material handling in warehousing is rapidly evolving. According to a recent industry report, the demand for automation in warehousing is expected to grow at a rate of 15% annually. This shift reflects the need for efficiency and productivity. Companies are increasingly investing in robotics to streamline operations, reduce human errors, and cut labor costs.

Future trends indicate that artificial intelligence (AI) will significantly enhance robotics capabilities. For instance, robots will not only transport goods but also learn optimal routes within warehouses. This learning capability can lead to a 30% reduction in operational time. As warehouses become more complex, the integration of autonomous systems will be crucial. However, companies must invest in training personnel to work alongside these robots, which poses its own challenges.

Tips: Ensure that your staff receives proper training. This creates a more harmonious working environment. Also, consider the scalability of your robotic solutions. Adapting to future demands is essential. Keep in mind that technology should complement human roles, not replace them completely. Balancing human skills with robotic efficiency can yield the best results.

Future Trends in Material Handling Robotics for Warehousing Solutions

This chart illustrates the adoption rates of various material handling robots in modern warehousing solutions, highlighting the emerging trends in automation.

Related Posts

-

Wisconsin Automation Leading the Future of Robotics in Manufacturing with Industry 4.0 Insights

-

10 Surprising Ways Automation Machines are Transforming Small Businesses in 2023

-

Why Robotics Classes are Essential for Future Innovators: Insights and Stats

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency

-

10 Essential Tips for Implementing Robotic Automation in Your Business

-

How to Choose the Right Robotic Welder for Your Manufacturing Needs