How to Optimize Robotic Systems for Enhanced Performance and Efficiency?

In the rapidly evolving field of robotic systems, enhancing performance and efficiency is of utmost importance. Dr. Emily Carson, a leading expert in robotics, emphasizes, "Optimizing robotic systems can transform industries." This statement highlights the significant impact that optimized systems have on productivity and innovation.

Many industries rely on advanced robotic systems. These systems perform tasks with precision and speed. Yet, challenges remain in ensuring their optimal functioning. Factors such as integration, programming, and maintenance often require close attention. A small error in programming can lead to inefficiencies.

However, the journey to optimize robotic systems is not always straightforward. Continuous improvement often reveals new complexities. Striking the right balance between technology and human input can lead to better outcomes. As we delve into optimization strategies, recognizing areas for reflection and growth is crucial. The pursuit of improvement in robotic systems remains an ongoing challenge, yet the rewards can be substantial.

Understanding the Basics of Robotic Systems Optimization

Understanding robotic systems optimization is crucial for improving performance. Firstly, optimizing robotic systems involves fine-tuning their components and software. Research indicates that effective optimization can boost operational efficiency by up to 30%. Integrating artificial intelligence can help robots learn from their environments. This adaptability often leads to better task execution.

Tips: Regularly assess system performance metrics. Identify bottlenecks in processes. A single miscalculation can hinder efficiency.

Another critical aspect is maintaining hardware. A report from a leading industry analyst suggested that nearly 50% of robotic failures stem from wear and tear. Hence, preventive maintenance is vital. Skipping checkups can lead to costly downtimes.

Tips: Create a routine maintenance schedule. Replace worn parts promptly to ensure smooth operations. Small, consistent adjustments can yield significant improvements.

Robotic Systems Performance Optimization

Identifying Key Performance Metrics for Robotic Efficiency

Identifying key performance metrics is essential for optimizing robotic systems. These metrics help to measure efficiency and effectiveness. One crucial aspect is task completion time. Tracking how long a robot takes to perform a task reveals bottlenecks. A robot that consistently lags in time needs evaluation. Are its movements smooth? Is the software optimized?

Another metric is energy consumption. Robots that use excessive power may be less efficient. Monitoring energy usage can lead to improvements. For instance, reducing idle time can save energy. It is also valuable to assess the accuracy of tasks. A robot that frequently makes errors requires recalibration. How precise are its sensors? Are they adequately aligned? Recognizing these imperfections can lead to significant enhancements.

Lastly, user feedback is critical. Operators can provide insights missed in data analysis. They may notice usability issues or unexpected behaviors of the robotic systems. Encouraging open communication can foster improvements. Identifying and addressing these areas will ultimately support better performance and efficiency in robotic systems.

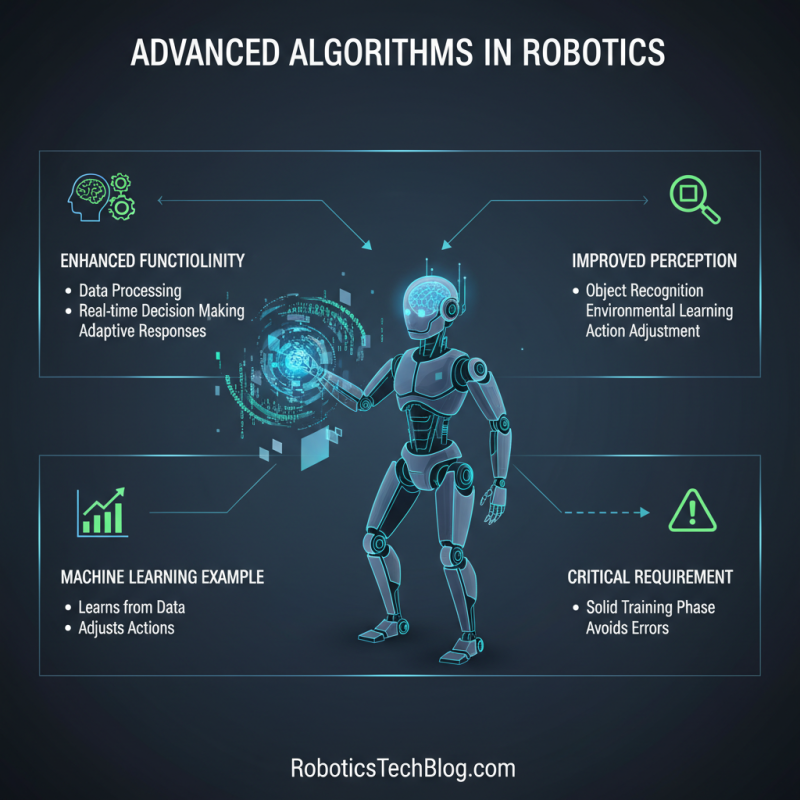

Implementing Advanced Algorithms for Enhanced Robotic Functionality

The integration of advanced algorithms into robotic systems can significantly enhance their functionality. These algorithms enable robots to process data more efficiently. They improve decision-making in real time, allowing for adaptive responses. For example, a robot equipped with machine learning algorithms can recognize objects better. It learns from its environment and adjusts its actions accordingly. However, this requires a solid training phase. Without proper training, the robot may make errors.

Testing and refining these algorithms is vital for performance. Real-world scenarios often differ from simulations. The algorithms need to adapt to unforeseen variables. Regular updates and adjustments can create more robust systems. This iterative process can uncover weaknesses. It’s important to identify where enhancements are needed. Overlooking flaws can lead to potential failures in critical tasks.

Additionally, the interplay of algorithms and hardware is crucial. An advanced algorithm may not perform if the hardware is subpar. Balancing the two components is challenging. Sometimes, optimizing one can lead to performance issues in the other. Continuous reflection on this balance is essential. Efficiency gains can sometimes mask deeper problems, necessitating ongoing evaluation.

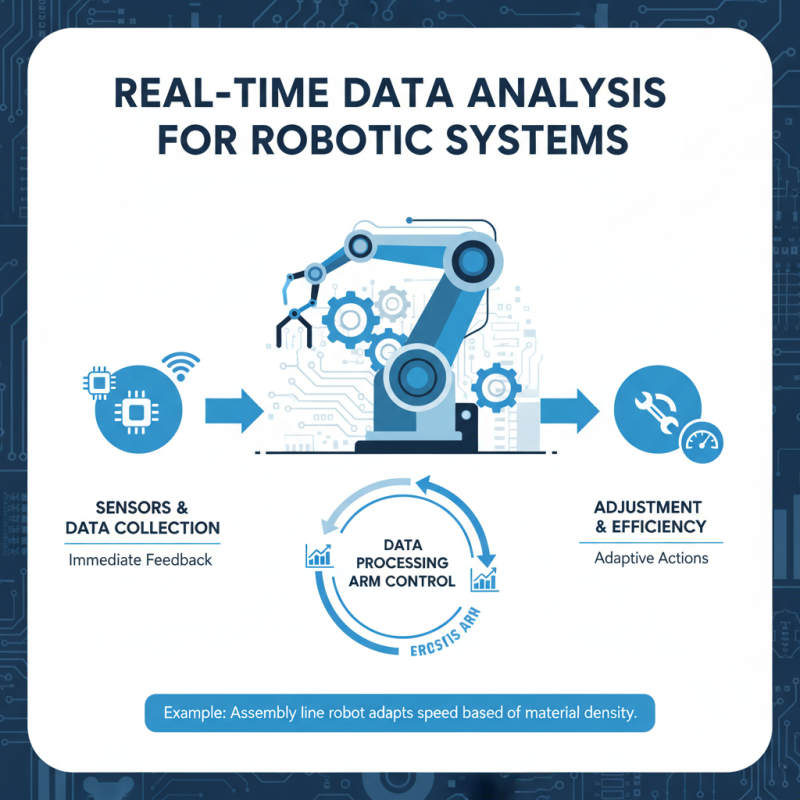

Integrating Real-Time Data Analysis for Continuous Improvement

Integrating real-time data analysis into robotic systems is crucial. This approach allows for immediate feedback and adjustments. For instance, a robotic arm working on an assembly line may need to adapt its speed based on varying material densities. Using sensors, it can collect data instantly and modify its actions. This capability enhances overall efficiency.

However, implementing real-time data systems isn’t always seamless. There are challenges. Data overload can lead to confusion. If a robot receives too much information too quickly, it might respond incorrectly or too slowly. Continuous improvement requires learning from mistakes. Sometimes, a simple bug can disrupt the entire process. Regular maintenance and updates are essential to ensure optimal performance.

Moreover, it's important to consider the human element. Operators must interpret data effectively. Poor communication can hinder performance. Training personnel to analyze real-time information is necessary. Finding the right balance between automation and human oversight is often difficult but vital for success. Continuous improvement in robotic systems involves refining both technology and human interactions.

Testing and Evaluating Enhanced Robotic Systems for Optimal Results

Testing and evaluating robotic systems is crucial for identifying performance gaps. Each tested robot must be assessed under various conditions. This helps to unveil both strengths and weaknesses. During trials, observe how robots respond to unexpected tasks. Some may excel, while others struggle to adapt.

Data collection is essential for analysis. Gather metrics such as speed, accuracy, and error rates. These numbers reveal where improvements are necessary. Sometimes, the robots may operate well but lack efficiency. For example, a robot might complete a task quickly, but it creates excessive wear and tear on its components. Reflecting on such findings can guide future design considerations.

User feedback is another layer in the evaluation process. Operators can provide insights that data alone may overlook. They might feel that certain functions are intuitive, while others are cumbersome. This feedback often leads to adjustments that enhance both usability and performance. However, not all feedback can be implemented right away. Prioritization becomes essential when resources are limited. Balancing enhancements with current system capabilities is an ongoing challenge.

How to Optimize Robotic Systems for Enhanced Performance and Efficiency?

| Dimension | Metric | Value | Notes |

|---|---|---|---|

| Speed | Traversing Speed | 1.5 m/s | Optimized for agility in dynamic environments. |

| Accuracy | Positioning Accuracy | ±2 mm | Enhanced sensors improve precision. |

| Efficiency | Energy Consumption | 500 W | Low power components for longer operation. |

| Load Capacity | Maximum Payload | 10 kg | Designed for versatile applications. |

| Response Time | System Response Delay | 30 ms | Faster processing algorithms implemented. |

Related Posts

-

Top 10 Robotic Automation Solutions You Need to Know?

-

Top 10 Ways to Define a Robot and Its Impact on Society?

-

Understanding the Essence of Robotics: What Defines a Robot in Today’s Tech Landscape

-

What Does a Robotics Technician Do and How to Become One?

-

Exploring the Future of Manufacturing with Robot Industrial Innovations

-

How to Harness Robotics and Automation for Your Business Success?