Why Robotic Automation is Transforming Industries Today?

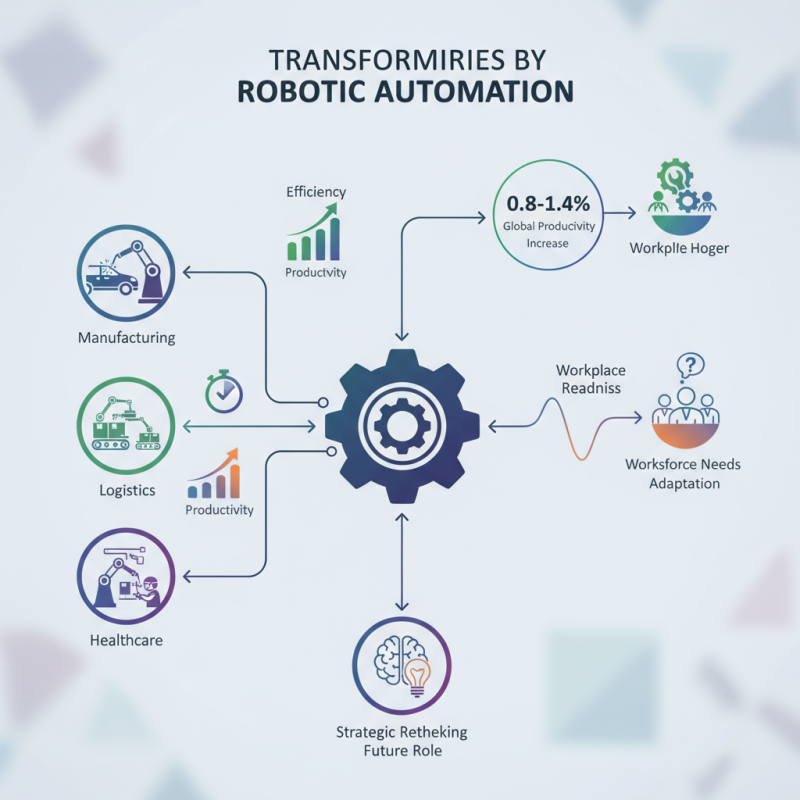

In recent years, robotic automation has transformed various industries, enhancing efficiency and productivity. According to a report by McKinsey & Company, automated solutions could increase global productivity by 0.8 to 1.4 percent annually. This trend is reshaping how businesses operate. Industry expert Dr. Emily Zhang states, “Robotic automation is not just a trend; it's a necessity for competitive survival.”

Many sectors are embracing robotic automation to streamline operations and reduce costs. Manufacturing, logistics, and healthcare have seen substantial improvements. For example, in manufacturing, integrating robots has led to production speed increases of over 30%. However, this shift brings challenges. Not all workplaces are ready for automation, and the workforce may face job displacements. A thoughtful reflection on these transformations is essential. Balancing technological advancement with workforce needs requires attention and care.

As industries continue to evolve, the role of robotic automation will become even more integral. Companies must adapt and rethink their strategies to harness the full potential of these advancements while being mindful of their impacts on employees and society.

The Rise of Robotic Automation in Modern Industries

The rise of robotic automation is reshaping various industries today. With advancements in artificial intelligence and robotics, businesses are experiencing unprecedented efficiency. A report from McKinsey suggests that automation could increase productivity by up to 30% in many sectors. Manufacturing, healthcare, and logistics are leading the way in adopting these technologies. Robots can perform tasks with precision and speed, reducing human error.

For companies considering automation, here’s a tip: start with small projects. Implementing automation gradually helps avoid costly mistakes. According to Deloitte, over 70% of organizations that adopted automation reported measurable improvements within the first year. However, companies must assess their workforce's readiness for change. Training staff is crucial but can be underestimated.

One area of concern is job displacement. According to a World Economic Forum report, by 2025, 85 million jobs may be displaced due to automation, while around 97 million new roles could emerge. This presents a paradox; innovation brings growth, yet it challenges employment. A balanced approach is essential. Adaptation is key for a smoother transition into this automated future.

Key Technologies Driving Robotic Automation Today

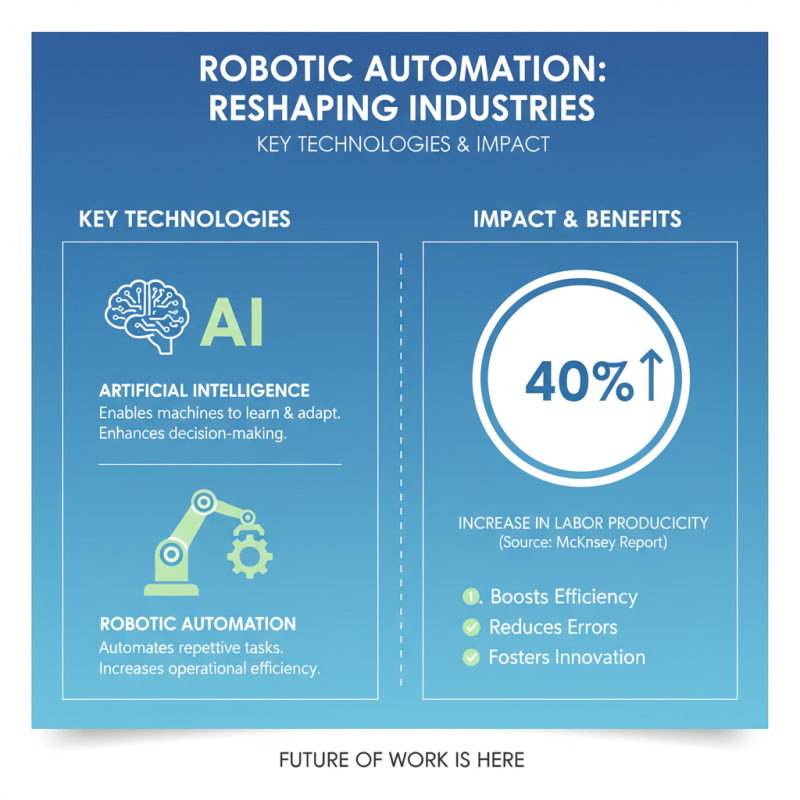

Robotic automation is reshaping industries through several key technologies. Artificial Intelligence (AI) is at the forefront, enabling machines to learn and adapt. According to a McKinsey report, AI can increase labor productivity by up to 40% in certain tasks. This technology helps in decision-making processes and enhances efficiency.

Another significant driver is the Internet of Things (IoT). IoT connects devices for real-time data exchange. A recent PwC study states that 50% of organizations plan to adopt IoT within the next year. This connectivity results in improved monitoring and predictive maintenance, reducing downtime in manufacturing.

Yet, challenges persist. The integration of robotic automation can be complex and costly. Many companies struggle with workforce adaptation as skilled labor needs evolve. As industries embrace these technologies, they must consider the upskilling of employees to meet new demands. Balancing automation with human talent remains a pressing concern. The path forward is not just about implementing technology, but about how to harmonize it with the existing workforce dynamics.

Impact of Robotic Automation on Workforce Dynamics

Robotic automation is reshaping the dynamics of the workforce dramatically. According to a McKinsey report, up to 800 million jobs could be displaced by 2030. This presents a challenge many industries must face. As machines take over repetitive tasks, employees are required to adapt and upskill.

In manufacturing, robotic arms perform tasks faster and with precision. A PwC study suggests that automating 50% of jobs could increase productivity by 25%. However, this boosts efficiency at a cost. Workers feel insecure about their roles. Mental health issues and job anxiety are rising. Displacement leads to a need for new job training programs.

Additionally, while robotics create new roles, not everyone can transition smoothly. Many workers lack the digital literacy required for emerging positions. A report from the World Economic Forum states that 54% of all employees will need significant reskilling by 2022. This gap highlights the growing divide between tech-savvy individuals and those left behind. The rapid pace of change often feels overwhelming. Addressing these disparities remains an essential part of the conversation on automation.

Benefits of Robotic Automation for Operational Efficiency

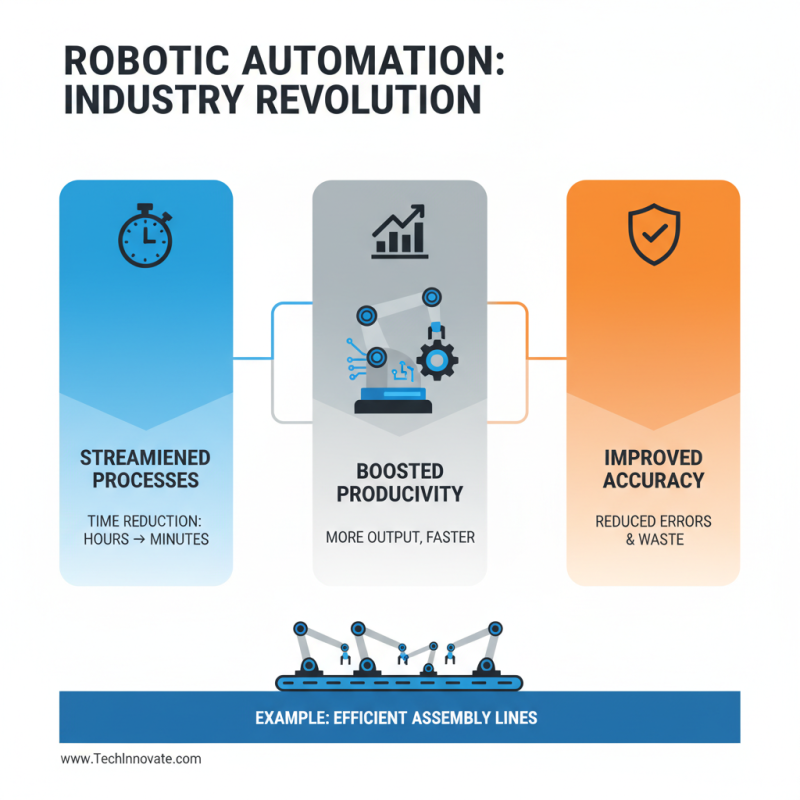

Robotic automation is changing how industries operate. It streamlines processes and boosts productivity. Tasks that once took hours can now be done in minutes. For example, assembly lines can run smoothly with robots doing repetitive tasks. This accuracy reduces errors and waste.

However, the benefits aren’t just about speed. Automation can improve safety in workplaces. Robots can handle dangerous tasks, reducing the risk of injury. But, there are challenges too. Implementing robotic systems requires upfront investments. Some workers may feel threatened by automation, leading to job security concerns.

Despite these drawbacks, the efficiency gained through automation is significant. Companies often experience increased output while lowering operational costs. The need for continuous improvement is essential. Balance is key between technology and workforce adaptation. A thoughtful approach ensures that both robots and employees can coexist successfully.

Future Trends in Robotic Automation Across Various Sectors

Robotic automation is reshaping industries in remarkable ways. Many sectors are seeing significant advancements. In manufacturing, robots streamline production processes. They reduce human error and enhance efficiency. This results in faster output and higher quality products. In logistics, automated systems handle inventory management. They optimize warehouse operations, minimizing delays.

Tips: Encourage teams to explore automation tools. Analyze workflows and identify repetitive tasks suitable for robots. Small changes can yield significant improvements.

In healthcare, robotic systems assist in surgeries. They enhance precision and reduce recovery times. However, concerns about job displacement persist. Balancing automation with human roles is crucial. Training programs must evolve to prepare workers for new tasks.

Tips: Invest in reskilling and upskilling initiatives. Create a culture of adaptability within the workforce. Future trends suggest that collaboration between humans and robots will be vital for success. As industries progress, ethical considerations become more prominent. Embracing these challenges can lead to sustainable growth.

Why Robotic Automation is Transforming Industries Today?

This chart illustrates the projected growth of robotic automation in various sectors over the next five years. The sectors covered are Manufacturing, Healthcare, Retail, Transportation, and Agriculture. Each sector is expected to experience significant advancements, showcasing the transformative impact of robotic automation across industries.

Related Posts

-

Wisconsin Automation Leading the Future of Robotics in Manufacturing with Industry 4.0 Insights

-

Revolutionizing Efficiency: How the Automation Industry is Expected to Surge by 30% by 2025

-

Top 10 Automation Machines Transforming Modern Industries Today

-

Top 10 Robotic Automation Solutions Transforming Businesses Today

-

10 Essential Tips for Implementing Robotic Automation in Your Business

-

10 Surprising Ways Automation Machines are Transforming Small Businesses in 2023