Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency

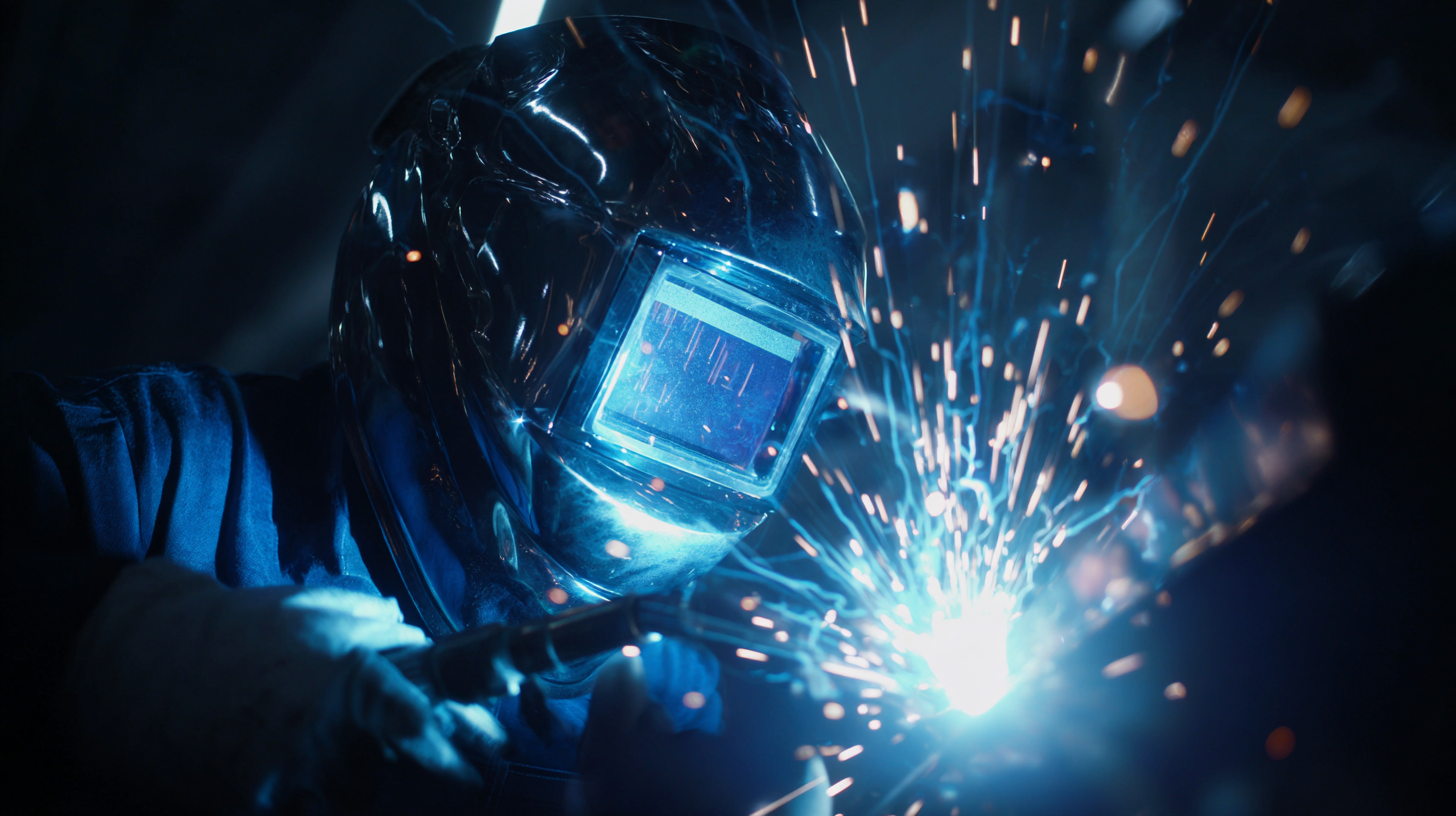

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount, and robotic welders are at the forefront of this transformation. As industries strive to enhance productivity while minimizing errors, the adoption of automation technologies, particularly robotic welding systems, has become a game changer. These advanced machines not only streamline the welding process but also ensure unparalleled consistency and quality in the final products.

By leveraging sophisticated algorithms and real-time data analysis, robotic welders can perform complex welding tasks with remarkable accuracy and speed, reducing labor costs and production times significantly. Moreover, their ability to operate in challenging environments allows manufacturers to push the boundaries of innovation, unlocking new possibilities for design and fabrication. In this article, we will explore how robotic welders are revolutionizing manufacturing efficiency, paving the way for a more automated and precise future in the industry.

By leveraging sophisticated algorithms and real-time data analysis, robotic welders can perform complex welding tasks with remarkable accuracy and speed, reducing labor costs and production times significantly. Moreover, their ability to operate in challenging environments allows manufacturers to push the boundaries of innovation, unlocking new possibilities for design and fabrication. In this article, we will explore how robotic welders are revolutionizing manufacturing efficiency, paving the way for a more automated and precise future in the industry.

The Rise of Robotic Welding in Modern Manufacturing

The rise of robotic welding in modern manufacturing marks a significant shift in the industry, driven by the need for efficiency and precision. As automation technologies continue to evolve, the global robotic welding market is poised for substantial growth, projected to expand from $8.1 billion in 2025 to $20.16 billion by 2032, with a compound annual growth rate (CAGR) of 13.9%. This surge emphasizes the increasing reliance on robotics to streamline manufacturing processes, enhance productivity, and improve product quality.

Robotic welding systems offer numerous advantages over traditional manual welding techniques. They provide consistent precision, reduce human error, and can operate continuously, thus maximizing throughput. As industries seek to modernize and maintain competitiveness, integrating robotic welding technology becomes essential. This adaptation not only addresses labor shortages but also aligns with the broader trend of industrial automation, which is projected to grow significantly, evidencing a shift towards smart manufacturing solutions worldwide. The focus on robotic welding signifies a future where innovation and efficiency are paramount in shaping the manufacturing landscape.

Benefits of Precision Welding: Accuracy and Consistency

Precision welding represents a significant advancement in manufacturing processes, particularly due to the integration of robotic welders. These automated systems excel in delivering unmatched accuracy and consistency, which are critical factors in production quality. By relying on precise algorithms and high-tech sensors, robotic welders can execute complex welds with minimal deviation, ensuring that every joint meets stringent specifications. This level of precision reduces waste and rework, enhancing overall efficiency in the manufacturing workflow.

In addition to accuracy, robotic welding systems contribute to a consistent output that meets the demands of modern production lines. Unlike human welders, robotic systems do not experience fatigue, allowing them to maintain a uniform standard across multiple operations. This consistency not only improves the structural integrity of the products but also builds trust with clients who expect reliable and repeatable results. As industries continue to seek innovative ways to improve efficiency, the adoption of robotic welders is proving to be a transformative step toward achieving high-quality manufacturing outcomes.

Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency - Benefits of Precision Welding: Accuracy and Consistency

| Metric | Before Robotic Welding | After Robotic Welding |

|---|---|---|

| Weld Accuracy (%) | 75% | 95% |

| Production Time (Hours) | 40 | 25 |

| Material Waste (%) | 20% | 5% |

| Labor Cost Reduction (%) | N/A | 30% |

| Product Defect Rate (%) | 10% | 2% |

Cost Efficiency: Reducing Waste and Labor Expenses

Robotic welders are transforming the landscape of manufacturing by dramatically enhancing cost efficiency. One of the primary advantages they offer is the significant reduction in waste materials. Traditional welding methods often lead to excess scrap and rework due to human error. In contrast, robotic welders consistently deliver precise results, minimizing the risk of defects and ensuring that every weld is as effective as possible. This precision not only reduces waste but also fosters a more sustainable manufacturing process.

**Tips: When implementing robotic welding, consider starting with a pilot program. This allows you to assess the initial efficiencies and make adjustments without overcommitting resources.** Furthermore, training your workforce to work alongside robotic systems is crucial. By upskilling employees, businesses can enhance overall productivity while harnessing the full potential of these advanced technologies.

Another area where robotic welders excel is in decreasing labor expenses. With automation taking over routine tasks, manufacturers can allocate human resources to more complex issues that require creative problem-solving and oversight. This strategic shift not only lowers labor costs but also elevates the overall skill level within the workforce, contributing to a more agile and knowledgeable team.

**Tips: Regular maintenance of robotic systems is essential to avoid downtime and ensure ongoing efficiency. Schedule routine check-ups to keep the technology operating at peak performance.** By integrating these practices, manufacturers can fully capitalize on the cost benefits offered by robotic welding solutions.

Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency

Integrating Robotics: Overcoming Challenges in Adoption

As the manufacturing industry embraces automation, the integration of robotic welders presents both exciting opportunities and significant challenges. One of the primary hurdles is the initial setup cost, which can be daunting for many manufacturers. To overcome this barrier, businesses should conduct a thorough cost-benefit analysis to understand the return on investment. Additionally, gradual implementation—starting with less critical welding tasks—can make the transition smoother and more manageable.

Another challenge lies in the skill gap; older workers may not be familiar with these advanced technologies. Providing comprehensive training programs can help bridge this knowledge divide. By fostering an environment of continuous learning, companies can equip their workforce with the skills necessary to thrive alongside robotics.

1. Start Small: Pilot robotics in a single production line to assess effectiveness before scaling up.

2. Invest in Training: Ensure your team is well-prepared to work with new technologies through ongoing education.

3. Seek Expert Guidance: Collaborate with robotics specialists to tailor solutions that fit your specific manufacturing needs.

Future Trends: Innovations Shaping the Next Generation of Welders

The welding industry is on the brink of significant transformation as innovations in robotic welding continue to take center stage. According to a report by the International Federation of Robotics, the adoption of industrial robots in manufacturing has surged, with projections of over 2.6 million operational robotic units globally by 2025. This rise directly impacts industries reliant on high-precision welding, where robotic systems offer improved accuracy, repeatability, and efficiency compared to traditional methods.

The welding industry is on the brink of significant transformation as innovations in robotic welding continue to take center stage. According to a report by the International Federation of Robotics, the adoption of industrial robots in manufacturing has surged, with projections of over 2.6 million operational robotic units globally by 2025. This rise directly impacts industries reliant on high-precision welding, where robotic systems offer improved accuracy, repeatability, and efficiency compared to traditional methods.

Emerging technologies such as Artificial Intelligence (AI) and Machine Learning (ML) are significantly shaping the next generation of robotic welders. These advancements allow robots to learn and adapt to complex welding tasks, optimizing parameters in real-time for better weld quality. A study from Markets and Markets estimates that the global market for robotic welding is expected to reach $6.9 billion by 2025, driven by the increased need for automation and reduced labor costs. As manufacturers invest in these cutting-edge technologies, the efficiency gains and quality enhancements promise to redefine what is possible in modern welding applications.