Wisconsin Automation Leading the Future of Robotics in Manufacturing with Industry 4.0 Insights

As the manufacturing landscape continues to evolve with the advent of Industry 4.0, Wisconsin Automation is at the forefront, driving innovation and efficiency in robotics. Industry 4.0 technologies, including the Internet of Things (IoT), artificial intelligence (AI), and advanced data analytics, are projected to add $14 trillion to the global economy by 2030, according to a report by McKinsey & Company.

Wisconsin Automation recognizes this shift and is strategically positioning itself to harness these technologies, integrating smart manufacturing practices that enhance productivity and reduce operational costs. The company's commitment to adopting automation solutions is evidenced by the growing trend of robot adoption, projected to exceed 2.5 million units sold annually by 2025, according to the International Federation of Robotics. As Wisconsin Automation leads the charge in this revolution, its innovative approaches are set to redefine the future of manufacturing and reinforce the importance of robotics in achieving sustainable growth and competitiveness in the global market.

The Role of Wisconsin in Shaping the Future of Robotics in Manufacturing

Wisconsin is emerging as a pivotal player in the evolution of robotics within the manufacturing sector, fueled by its commitment to embracing Industry 4.0 principles. The state’s rich combination of advanced manufacturing capabilities and innovative research institutions positions it uniquely to influence robotic technologies. Wisconsin’s manufacturers are increasingly integrating intelligent automation, thus enhancing productivity and efficiency across the board. This transformation is not only reshaping traditional manufacturing processes but is also paving the way for the development of smart factories that utilize data and connectivity to drive operational excellence.

Moreover, educational institutions in Wisconsin are collaborating closely with industries to cultivate a skilled workforce adept in robotics and automation. Programs focusing on robotics engineering and computer science are producing graduates who are ready to tackle the challenges of modern manufacturing. This synergy between academia and industry is critical as it ensures a continuous flow of fresh ideas and technological advancements, positioning Wisconsin as a crucial hub for the future of manufacturing robotics. As the state continues to innovate and lead, it will play a significant role in setting global standards and inspiring other regions to adopt similar strategies in technology-driven manufacturing.

Key Insights from Industry 4.0: Transforming Manufacturing Processes

The advent of Industry 4.0 has marked a significant transformation in manufacturing processes, particularly as organizations turn towards automation and smart technologies. According to a report by the International Federation of Robotics, the global market for industrial robots is projected to reach $66 billion by 2025, underscoring the crucial role that automation plays in enhancing operational efficiency. This shift not only optimizes production lines but also empowers manufacturers to adapt to changing market demands swiftly.

Integrating advanced data analytics and IoT into manufacturing systems allows for real-time monitoring and predictive maintenance, which can reduce downtime by up to 30%, as noted in a study by McKinsey & Company. Furthermore, manufacturers harnessing Industry 4.0 technologies can expect a 5-15% increase in productivity, showcasing how automation is leading the charge in redefining the manufacturing landscape. Companies like Wisconsin Automation are at the forefront of this change, implementing smart robotics and data-driven insights to facilitate a new era of manufacturing that is more agile and resilient.

Innovative Robotics Solutions Emerging from Wisconsin's Manufacturing Sector

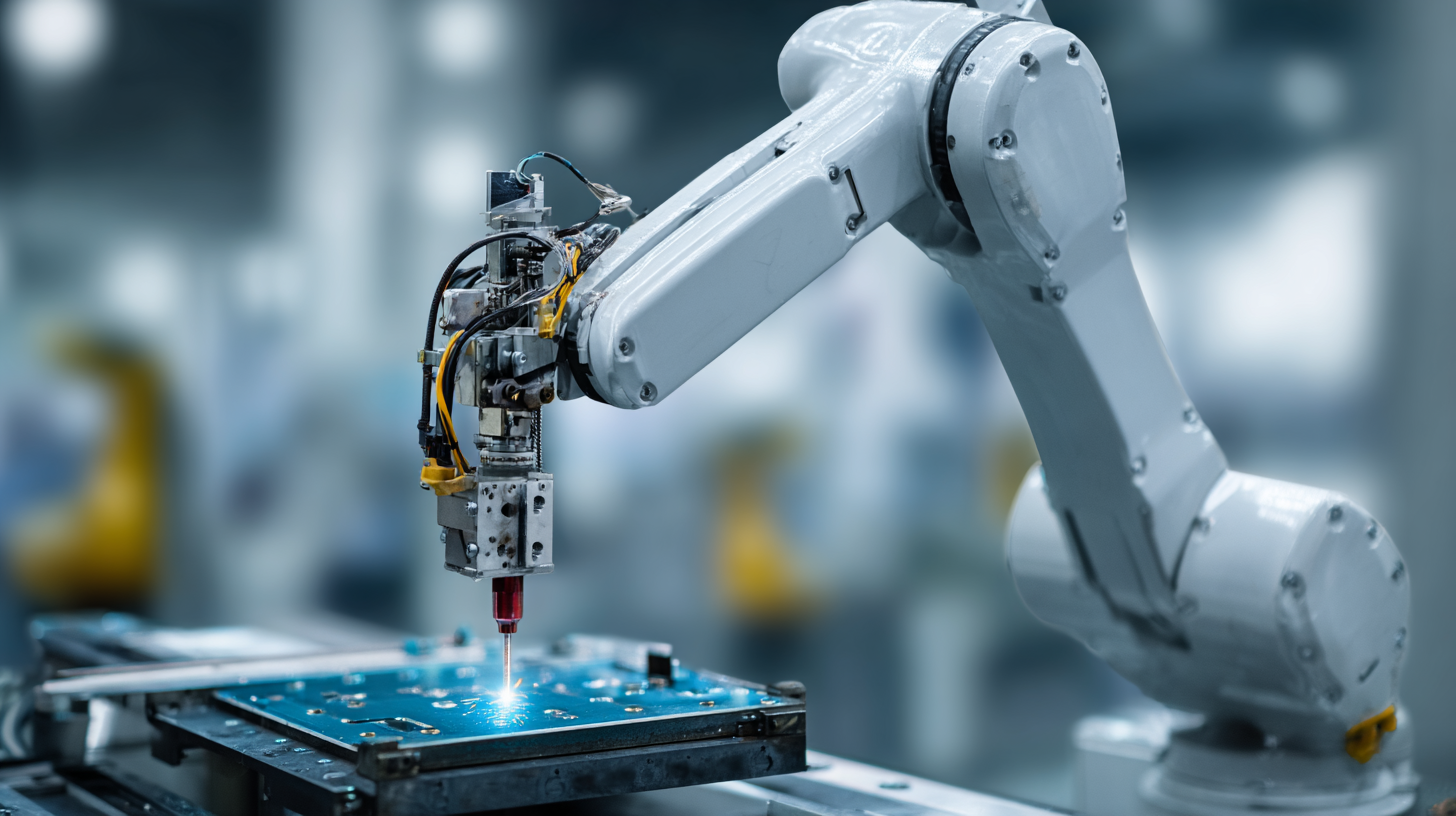

Wisconsin's manufacturing sector is at the forefront of innovative robotics solutions, harnessing the principles of Industry 4.0 to revolutionize production processes. With a strong emphasis on automation, local companies are increasingly integrating advanced robotics systems that enhance efficiency, reduce operational costs, and improve product quality. These emerging solutions not only streamline workflows but also offer unparalleled precision, enabling manufacturers to meet the growing demands for customized products in shorter timeframes.

The collaboration between academic institutions and industry leaders in Wisconsin plays a crucial role in fostering this robotic innovation. Research centers are developing cutting-edge technologies that are quickly adopted by manufacturers, ensuring that the state's industrial landscape remains competitive on a global scale. This synergy between education and industry has led to a surge in skilled workforce development, positioning Wisconsin as a hub for automation expertise. As businesses continue to embrace these advancements, they are actively shaping the future of robotics in manufacturing, setting the stage for a more automated and efficient industrial environment.

Challenges and Opportunities in Implementing Robotics with Industry 4.0

Implementing robotics in manufacturing under the framework of Industry 4.0 presents a range of challenges and opportunities. Manufacturers often face hurdles such as integrating advanced technologies with existing systems, overcoming employee resistance to change, and addressing data security concerns. Moreover, the high initial costs associated with robotic systems can deter small to medium-sized enterprises from making the leap into automation. However, recognizing these challenges allows companies to strategically navigate them, ultimately leading to enhanced efficiency and productivity.

Tip: Start small by piloting robotics in specific areas of your manufacturing process. This approach helps identify potential issues early on and allows your team to adapt gradually.

On the opportunity side, robotics significantly enhance production speed and precision. Industry 4.0 emphasizes real-time data analytics, enabling manufacturers to monitor and optimize operations continuously. This technological synergy not only increases output but also improves product quality, which can lead to higher customer satisfaction and increased market share.

Tip: Invest in training your workforce to understand and operate new robotic systems. Empowering your employees is crucial for successful implementation and maintaining a competitive edge in the evolving market.

Case Studies: Successful Integration of Robotics in Wisconsin Industries

Wisconsin has emerged as a pioneering hub for automation in the manufacturing sector, particularly through the successful integration of robotics. Case studies from various industries within the state showcase how businesses are leveraging Industry 4.0 insights to enhance productivity and efficiency. For instance, a recent report from the American Robotics Association noted that manufacturers who implemented robotic solutions saw productivity increases of up to 30%. This growth is particularly evident in sectors like automotive and food processing, where precision and speed are critical.

In one notable case, a Wisconsin-based automotive manufacturer integrated collaborative robots (cobots) on their assembly line, resulting in a 25% reduction in production time. This transition not only optimized their workflow but also allowed human workers to focus on more complex tasks, reflecting a significant shift in the workplace dynamic. Furthermore, a study by the National Association of Manufacturers indicated that over 80% of manufacturers are considering automation solutions, underlining the growing trend toward robotic integration across various sectors in Wisconsin. These examples illustrate a transformative wave in the manufacturing landscape, driven by innovative robotics technology and strategic insights from Industry 4.0.

Related Posts

-

10 Surprising Ways Automation Machines are Transforming Small Businesses in 2023

-

Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency

-

Exploring the Future of Automation Through Fanuc Robots Advancements in Technology

-

Unlocking Business Efficiency with Robotic Process Automation Software Insights from Recent Industry Trends

-

Exploring the Future of Manufacturing with Robot Industrial Innovations