How to Choose the Right Robotic Welder for Your Manufacturing Needs

In today’s competitive manufacturing landscape, the integration of advanced technologies is pivotal for achieving efficiency and precision. Among these technologies, the adoption of robotic welders has surged, with industry reports indicating that the global market for robotic welding is projected to reach USD 6.8 billion by 2026, growing at a CAGR of 7.5% from 2021. This growth is driven by the need for automation in manufacturing processes, as businesses strive to enhance productivity while maintaining high standards of quality. As highlighted by Dr. Linda Smith, a leading expert in robotic automation, "The right robotic welder can significantly reduce operational costs and improve the quality of welds, empowering manufacturers to meet complex demands."

Choosing the appropriate robotic welder requires careful consideration of various factors, including the specific needs of the production line, the materials being used, and the complexity of welding tasks. Robotic welders come in different configurations, each designed to cater to distinct manufacturing requirements. With advancements in technology, modern robotic welders are equipped with sophisticated sensors and adaptive capabilities that allow for greater flexibility and optimization. As manufacturers look to streamline operations and enhance their competitive edge, understanding the nuances of selecting the right robotic welder becomes essential for success in a rapidly evolving marketplace.

Factors to Consider When Selecting a Robotic Welder

When selecting a robotic welder for your manufacturing needs, several crucial factors must be considered to ensure optimal performance and efficiency. First, assess the type of welding processes involved in your operations. Different robotic welders are designed for specific methods like MIG, TIG, or spot welding. Understanding the primary techniques required will help narrow down your options and ensure compatibility with existing machinery and workflows.

Another important aspect to evaluate is the size and complexity of the parts being welded. The reach and payload capacity of the robotic welder should be matched to the dimensions and weight of the materials. This consideration will not only enhance productivity but also reduce the risk of errors during the welding process. Additionally, look into the software capabilities of the robotic welder, as advanced programming features can facilitate easier setup and modifications for various tasks, leading to greater flexibility in your manufacturing processes.

Types of Robotic Welding Technologies Available

When selecting the right robotic welder for your manufacturing operations, it’s crucial to understand the various types of robotic welding technologies available on the market. The most common forms include arc welding robots, spot welding robots, and laser welding robots. According to a report by IndustryARC, the global robotic welding market is projected to grow at a compound annual growth rate (CAGR) of 8.5% from 2021 to 2026, highlighting the increasing importance of these technologies in modern manufacturing processes.

Arc welding robots are favored for their versatility and ability to perform a range of tasks, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. They are particularly effective in industries such as automotive and construction, where strong welds are essential. On the other hand, spot welding robots are predominantly used in the assembly of sheet metal components, offering faster production speeds and precise welds, making them ideal for high-volume manufacturing. Meanwhile, laser welding robots are gaining traction due to their high precision and ability to create clean, narrow weld seams, suitable for industries requiring minimal post-weld treatment.

As manufacturers strive for greater efficiency and output, understanding these welding technologies is vital. A report by Mordor Intelligence indicates that the increase in automation in the manufacturing sector is pushing the demand for robotic welding solutions, particularly as companies seek ways to enhance productivity and reduce labor costs. Choosing the appropriate robotic welder thus hinges on an in-depth evaluation of these technologies and their suitability for specific manufacturing needs.

Understanding Your Production Volume and Application Requirements

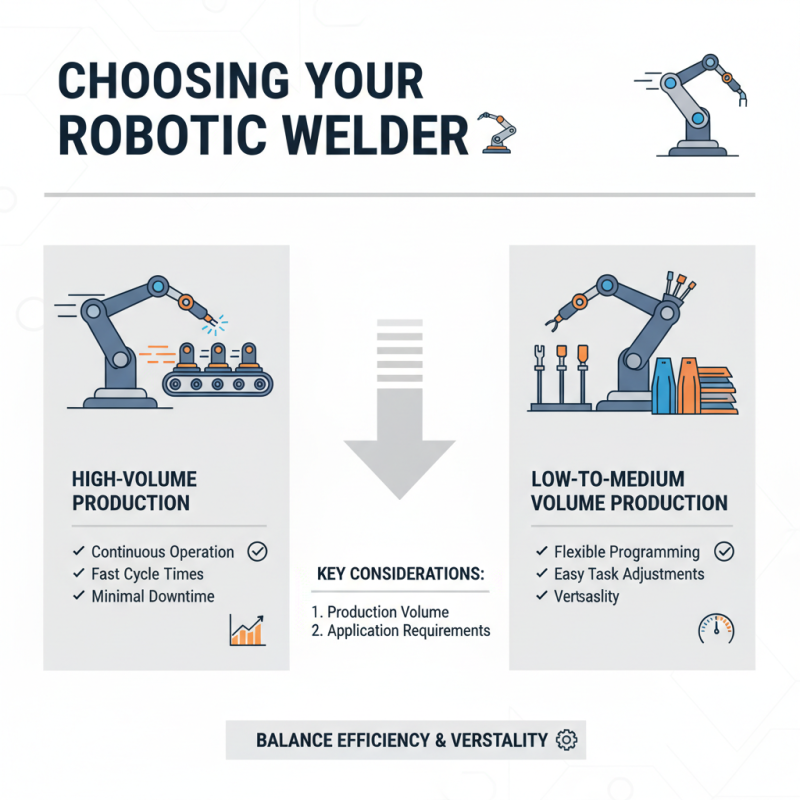

When selecting the right robotic welder for your manufacturing needs, understanding your production volume and application requirements is crucial. Assessing production volume involves evaluating the number of units you plan to produce within a specific timeframe. High-volume production lines often benefit from faster, more efficient robotic systems that can operate continuously with minimal downtime. Conversely, for low to medium volume applications, flexibility in the robot's programming and easy adjustments for different tasks become more important, allowing for a balance between efficiency and versatility.

Moreover, application requirements play a significant role in the selection process. Different welding processes, such as MIG, TIG, or spot welding, may be better suited depending on the materials being joined and the desired weld quality. Consider the type of materials—steel, aluminum, stainless steel, or other composites—as this will influence the choice of welding technology and the necessary equipment features. Additionally, factors like weld joint configuration and accessibility should be taken into account to ensure the robotic welder can perform optimally in your specific production environment. Tailoring the robotic solution to your unique manufacturing context will improve overall productivity and quality.

Evaluating Cost vs. Performance in Robotic Welding Solutions

When evaluating robotic welding solutions, one of the key considerations is the balance between cost and performance. Organizations often face a dilemma: should they invest in higher-end equipment that touts superior efficiency and precision, or opt for a more budget-friendly option that may compromise on some performance metrics? Understanding the specific manufacturing requirements is essential for making an informed decision. For instance, operations that demand high throughput and minimal downtime may find that the initial investment in a more advanced welder pays off through increased productivity and lower long-term costs.

Another critical aspect is the operational flexibility of the robotic welder. Factors such as the range of materials, the type of welding processes it supports, and the complexity of tasks it can handle should weigh heavily in any assessment. A system that can adapt to various projects may save time and costs associated with downtime or reprogramming. Therefore, while the upfront cost is important, it should not overshadow the potential gains in efficiency, flexibility, and overall performance that a well-chosen robotic welding solution can provide. Thoroughly analyzing these aspects will lead to a more effective investment that aligns with your manufacturing needs.

Community and Support Resources for Robotic Welder Users

When investing in a robotic welder, it's essential to recognize the importance of community and support resources that come with it. A strong network of users can provide invaluable insights into best practices, troubleshooting techniques, and innovative applications of robotic welding technology. Online forums, social media groups, and dedicated user communities serve as platforms for sharing experiences and solutions. Engaging with these resources allows users to tap into a wealth of knowledge and fosters connections that can help enhance the effectiveness of their robotic welding operations.

Additionally, many manufacturers and distributors offer support programs that can aid users in maximizing their investment. These programs often include training sessions, user manuals, and access to technical support teams that can guide users through common challenges. By participating in these initiatives, operators can better understand their equipment, improve their skills, and stay abreast of the latest advancements in robotic welding technology. Leveraging such community resources not only boosts individual proficiency but also contributes to overall productivity and efficiency in manufacturing environments.

Robotic Welder Efficiency by Application Type

Related Posts

-

10 Essential Tips for Choosing Robotic Welding Systems for Your Business

-

Unlocking Precision: How Robotic Welders Are Revolutionizing Manufacturing Efficiency

-

Top 10 Benefits of Using Robotic Welders in Modern Manufacturing

-

Top 10 Robotic Automation Solutions Transforming Businesses Today

-

Top 5 Reasons Why Fanuc Robots Lead the Automation Industry with 20 Percent Market Share

-

Exploring the Future of Automation Through Fanuc Robots Advancements in Technology